A method of manufacturing a mems element

A technology of components and micro-electromechanical components, which is applied in the field of manufacturing electronic devices, can solve the problem of difficulty in controlling the removal of sacrificial layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

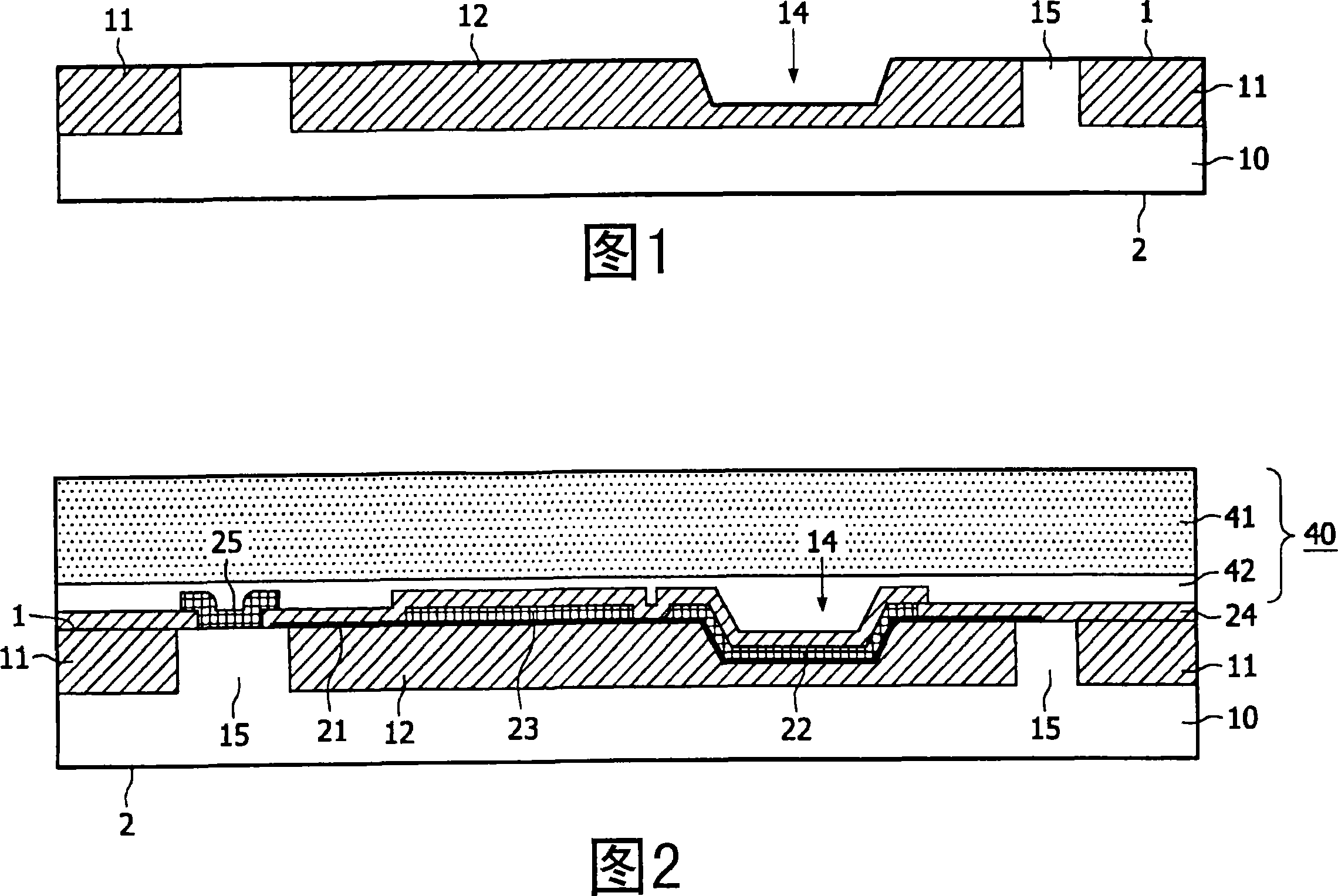

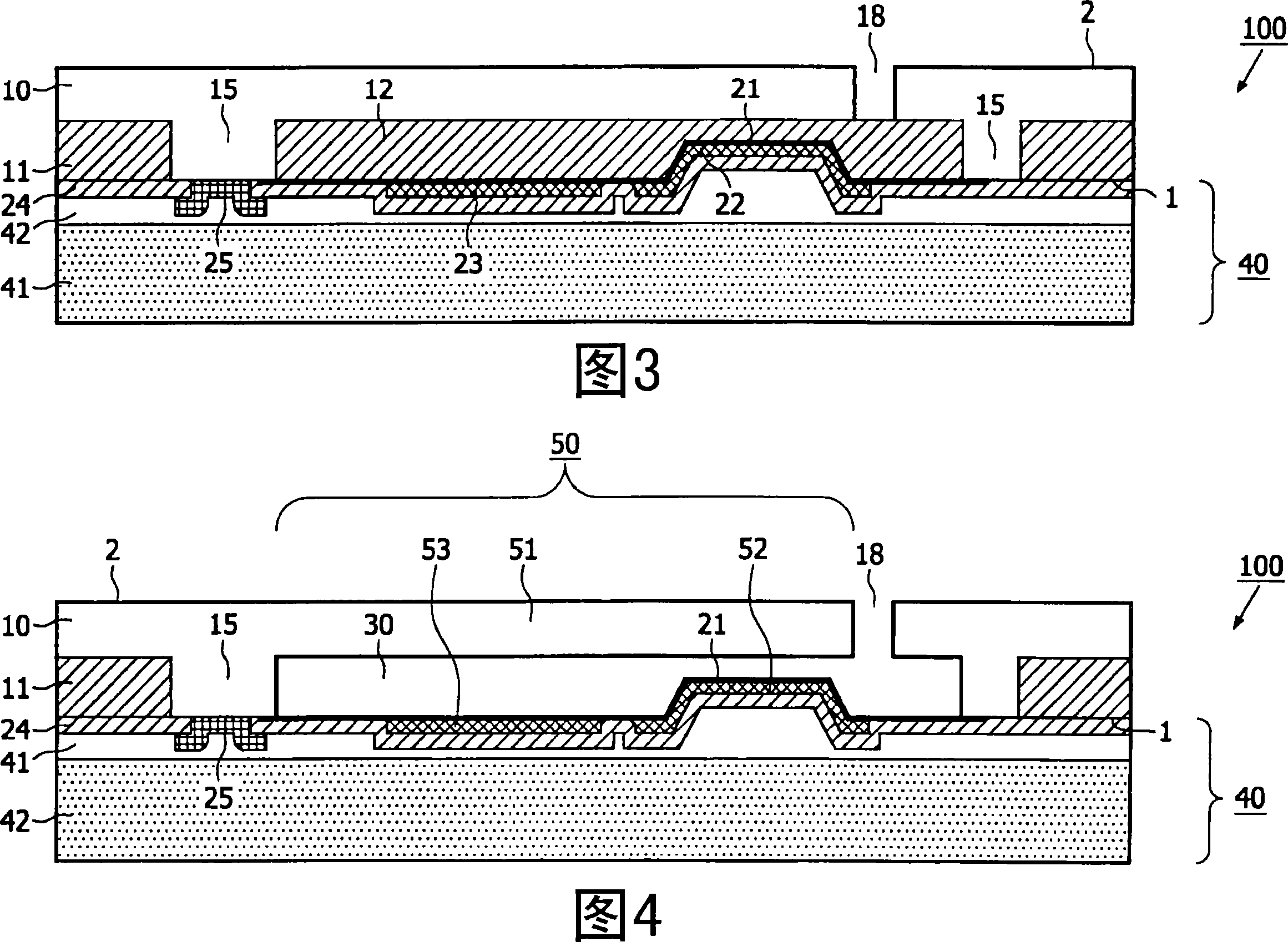

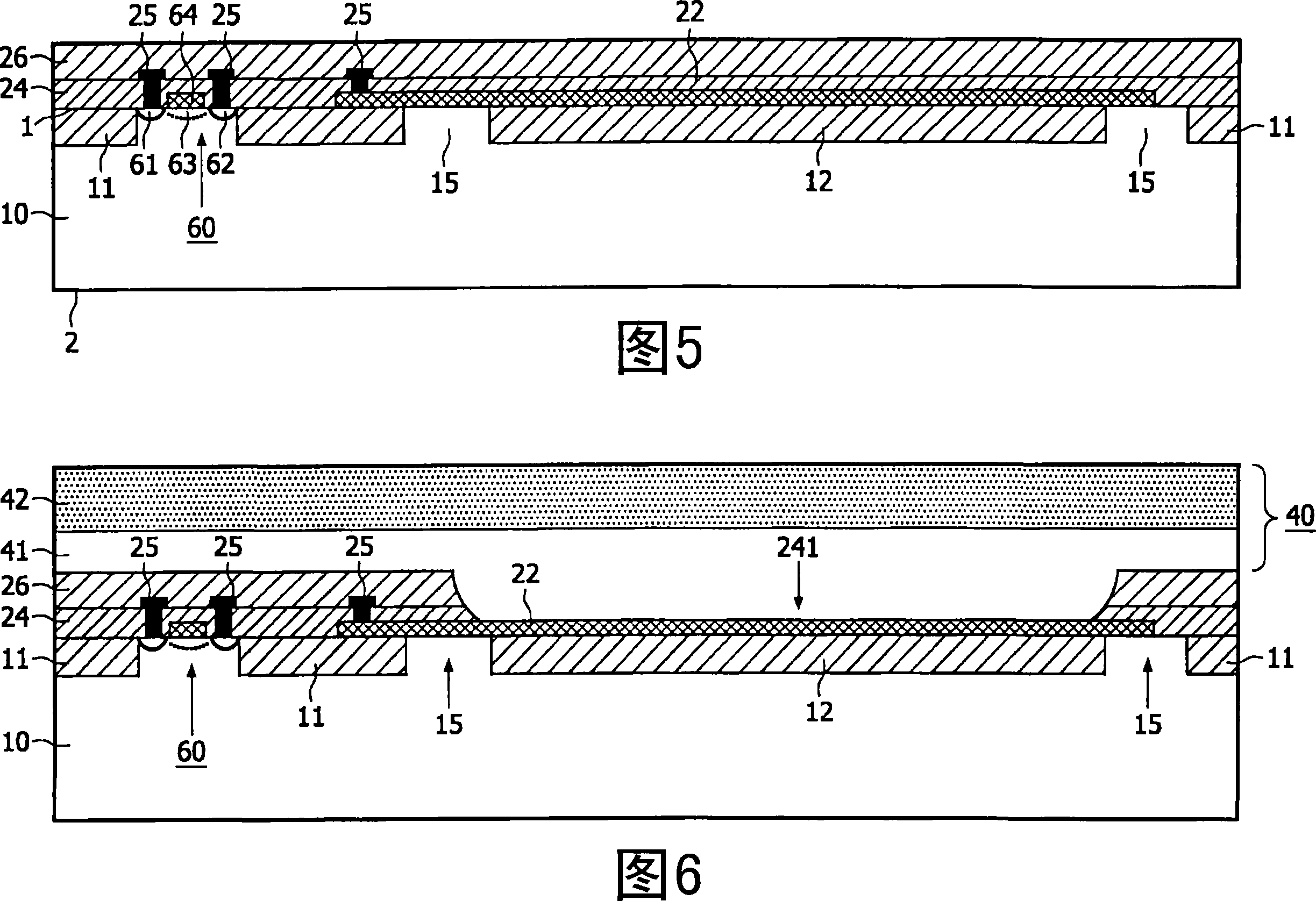

[0043] 1-4 show a first embodiment of the method of the invention in cross-sectional view.

[0044] FIG. 1 shows a substrate 10 having a first surface 1 , and a second surface 2 . In this case, the substrate 10 is a silicon substrate, which is doped n-type or p-type so as to be sufficiently conductive. The dopants extend in particular to a depth of 10-20 microns. On the first surface 1 , the substrate 10 has been locally oxidized and at least one pillar 15 , the sacrificial layer 12 and other parts of the oxide layer 11 have been formed. This oxidation is performed by a process known as shallow trench oxidation as described in S.M. Sze, Semiconductor Physics and Technology, in this example the MEMS element is formed with first and second gaps as shown in the other figures. For this purpose, sacrificial layer 12 is structured again to form recesses 14 . Although not shown here, the substrate 10 may also include any other components, in particular transistors and diodes.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com