Preparation method of nano-composite hydrogel and application of nano-composite hydrogel in promoting healing of diabetic wounds

A nano-composite, wound-healing technology, applied in pharmaceutical formulations, prostheses, bandages, etc., can solve the problems of no breakthrough in chronic wound treatment, low delivery efficiency, low immunogenicity, etc., and achieve broad market application prospects and good consumption Action, selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

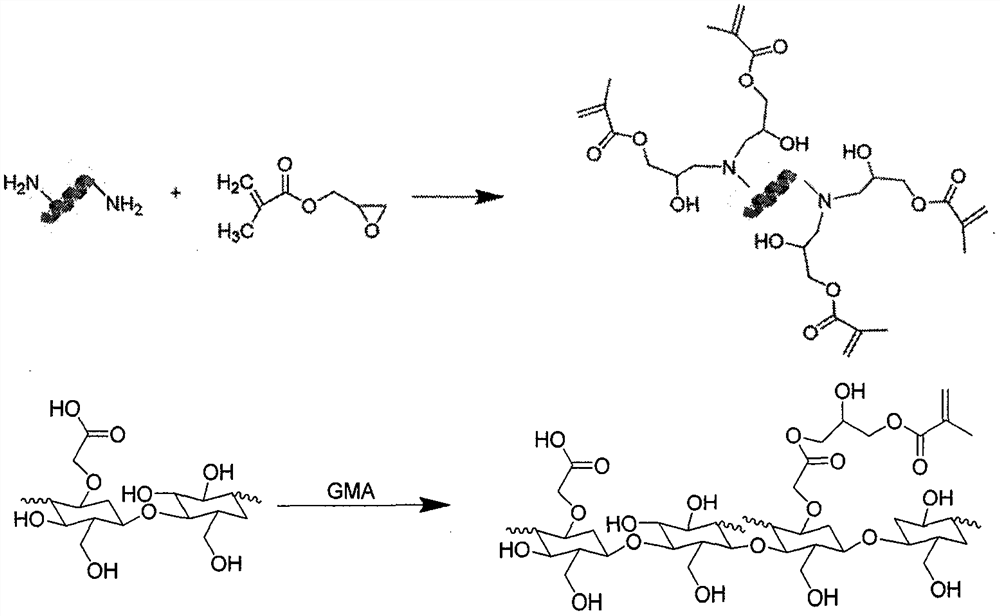

[0055] A kind of preparation method of nanocomposite hydrogel is as follows (material modification method such as figure 1 shown):

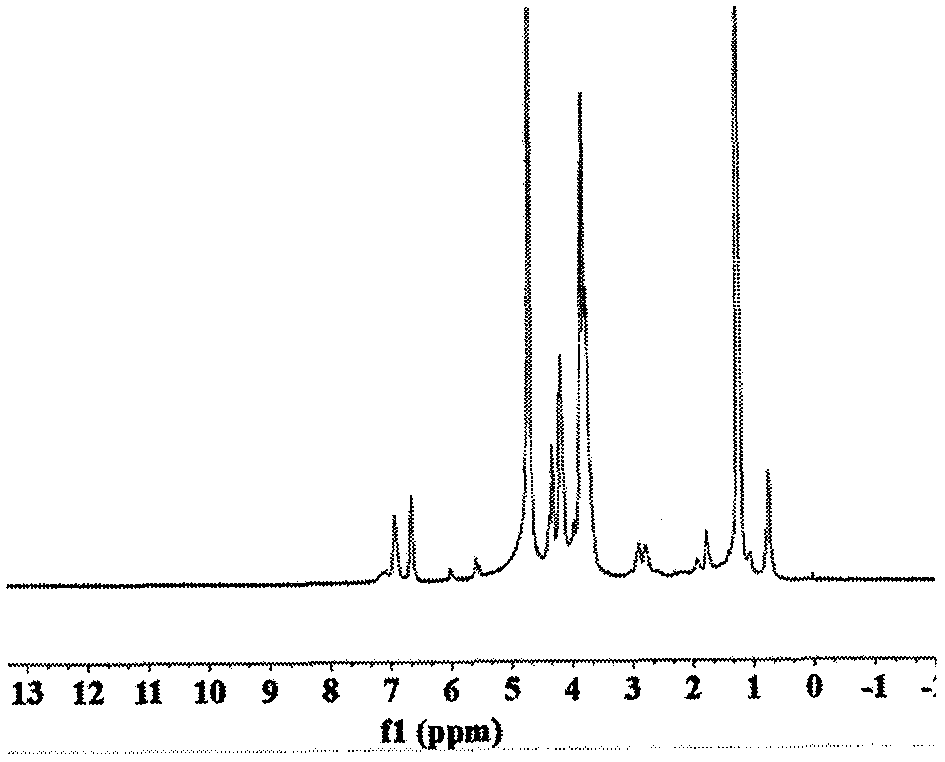

[0056](1) Add soluble silk fibroin (molecular weight: 2,000 to 10,000 Daltons) powder in deionized water to make a 10g / L silk fibroin aqueous solution. Under the conditions, 0.5 equivalent of glycidyl methacrylate (GMA) was added and stirred to dissolve, and the reaction was continued for 6 hours. After the reaction, the reaction solution was transferred to a dialysis bag and dialyzed in deionized water for 3 days. The purified solution obtained after dialysis was lyophilized to obtain glycidyl methacrylate modified silk fibroin polymer (SF-GMA), and the lyophilized sample was dissolved and characterized by hydrogen nuclear magnetic resonance spectrometer to obtain the sample. 1 H-NMR spectrum as figure 2 shown.

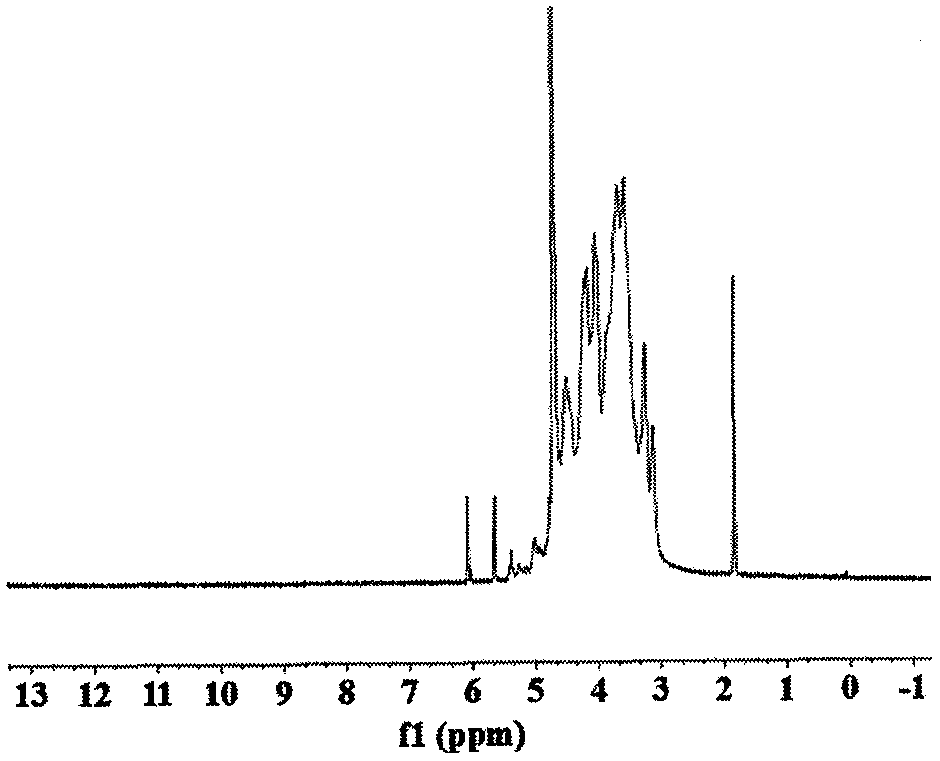

[0057] (2) Add carboxymethyl cellulose (molecular weight: 90,000 Daltons) powder into deionized water to make a 10g / L carboxymeth...

Embodiment 2

[0062] (1) Add soluble silk fibroin (molecular weight: 2,000 to 10,000 Daltons) powder in deionized water to make a 10g / L silk fibroin aqueous solution. After it is completely dissolved, adjust the pH to 4.7. Under the conditions, 1.0 equivalent of glycidyl methacrylate (GMA) was added and stirred to dissolve, and the reaction was continued for 6 hours. After the reaction, the reaction solution was transferred to a dialysis bag and dialyzed in deionized water for 3 days. The purified solution obtained after dialysis was freeze-dried to obtain glycidyl methacrylate-modified silk fibroin polymer (SF-GMA).

[0063] (2) Add carboxymethyl chitosan (carboxylation degree 80%) powder to deionized water to make 20g / L carboxymethyl chitosan aqueous solution, after completely dissolving, adjust the pH to 5.0, Add 1 equivalent of glycidyl methacrylate (GMA) under the condition of ℃ and stir to dissolve, and continue to react for 8h. After the reaction, the reaction solution was transfer...

Embodiment 3

[0067] (1) Add gelatin (molecular weight: 50,000 to 100,000 Dalton) particles in deionized water, dissolve at 40°C to make a 50g / L gelatin aqueous solution, and after completely dissolving, add 1 equivalent of formazan at a reaction temperature of 50°C Acrylic anhydride (MA) was stirred and dissolved, and the reaction was continued for 2h. After the reaction, the reaction solution was transferred to a dialysis bag and dialyzed in deionized water for 3 days. The purified solution obtained after dialysis was freeze-dried to obtain methacrylic anhydride-modified gelatin polymer (GelMA).

[0068] (2) Add carboxymethyl cellulose (molecular weight: 90,000 Dalton) powder into deionized water to make 20g / L carboxymethyl cellulose aqueous solution. After it is completely dissolved, adjust the pH to 5.0, Under the conditions, 1.5 equivalents of glycidyl methacrylate (GMA) was added and stirred to dissolve, and the reaction was continued for 6 hours. After the reaction, the reaction so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com