Main oil pressure electromagnetic valve maintenance tool and using method thereof

A solenoid valve, main oil pressure technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of the main oil pressure solenoid valve shell can not be reused, high cost, waste of resources, etc., to achieve easy completion of the flaring process, expansion Round mouth and easy insertion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

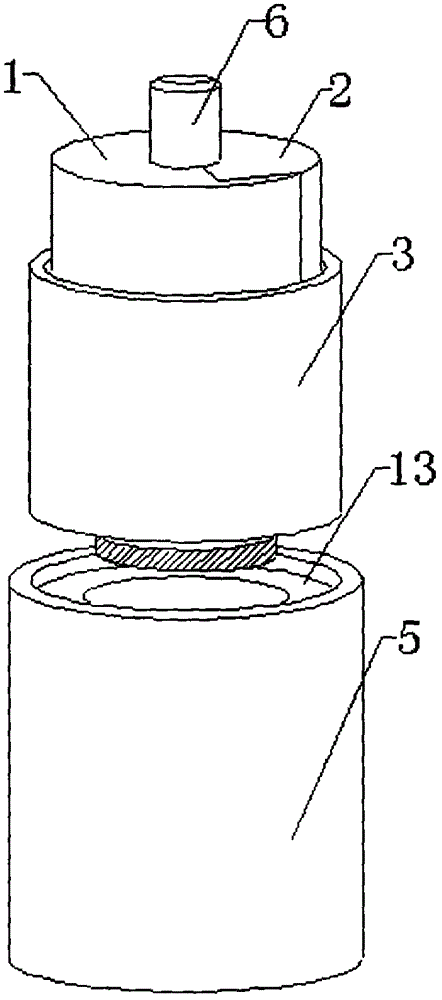

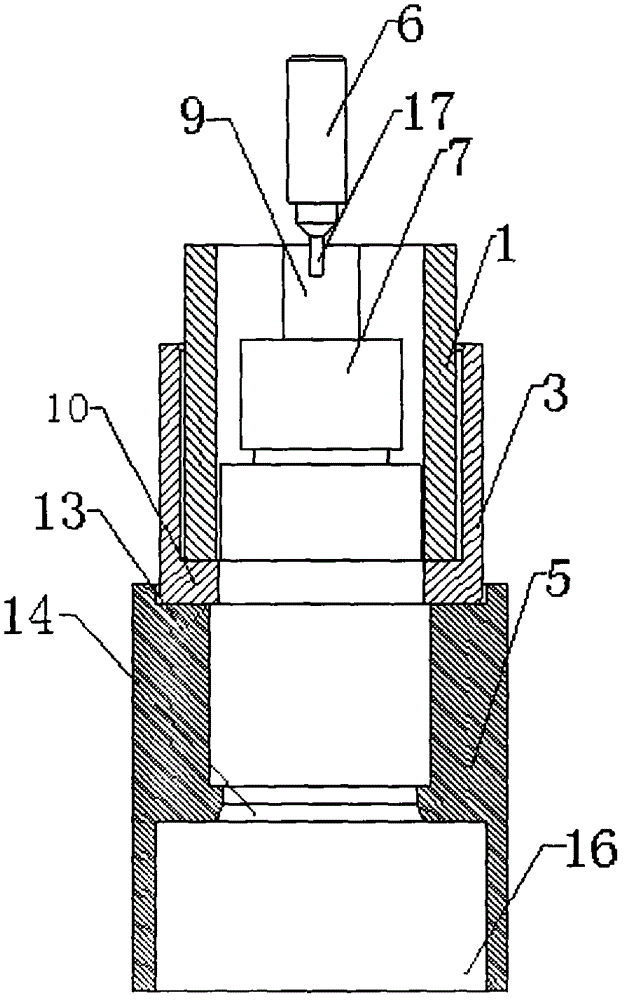

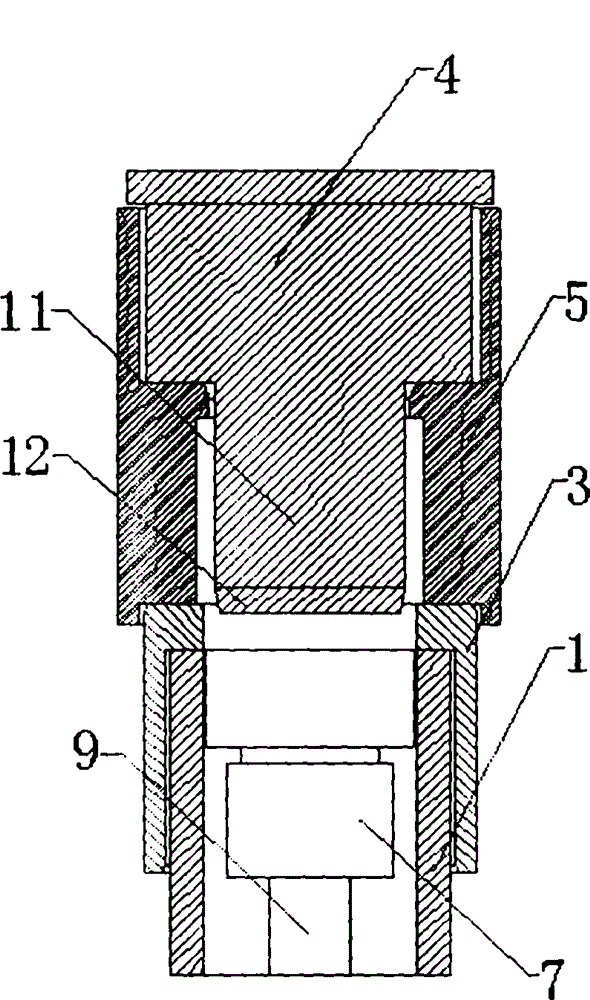

[0031] Such as Figure 1-12 As shown, a main oil pressure solenoid valve maintenance tool, which includes a valve fixing seat A1 for fixing the main oil pressure solenoid valve, a valve fixing seat B2 for fixing the main oil pressure solenoid valve, and a valve fixing seat A1 for fixing the main oil pressure solenoid valve. and valve fixing seat B2 quick release sleeve 3, expansion shaft for expanding the opening of the main oil pressure solenoid valve casing 4, for raising the valve fixing seat A1, valve fixing seat B2 and for adjusting the main oil pressure solenoid valve casing The necking sleeve 5 for tightening the opening, the core rod 6 for ejecting the internal components of the main oil pressure solenoid valve, the valve fixing seat A1 is provided with a valve fixing groove A7 inside, and the valve fixing seat B2 is provided inside There is a valve fixing groove B8, the valve fixing seat A1 and the valve fixing seat B2 are buckled and connected, the buckling structure...

Embodiment 2

[0042] Such as Figure 1-12 As shown, a main oil pressure solenoid valve maintenance tool, which includes a valve fixing seat A1 for fixing the main oil pressure solenoid valve, a valve fixing seat B2 for fixing the main oil pressure solenoid valve, and a valve fixing seat A1 for fixing the main oil pressure solenoid valve. and valve fixing seat B2 quick release sleeve 3, expansion shaft for expanding the opening of the main oil pressure solenoid valve casing 4, for raising the valve fixing seat A1, valve fixing seat B2 and for adjusting the main oil pressure solenoid valve casing The necking sleeve 5 for tightening the opening, the core rod 6 for ejecting the internal components of the main oil pressure solenoid valve, the valve fixing seat A1 is provided with a valve fixing groove A7 inside, and the valve fixing seat B2 is provided inside There is a valve fixing groove B8, the valve fixing seat A1 and the valve fixing seat B2 are buckled and connected, the buckling structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com