Hexagonal flange type nut conveyor

A flange type, conveyor technology, applied in the direction of conveyors, conveyor objects, vibrating conveyors, etc., can solve the problems that affect the normal production, are not suitable for conveying hexagonal flange nuts, and are prone to overlap and sticking. To achieve the effect of convenient inspection and dredging, full automation and prevention of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

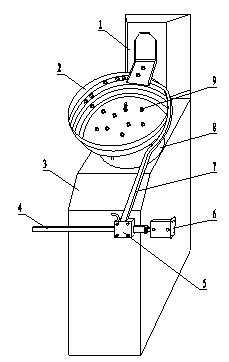

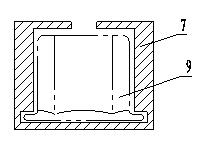

[0017] see figure 1 , the present invention mainly includes a hopper 1, a vibrating plate 2, a profiling pipe 7 and a distributor 5.

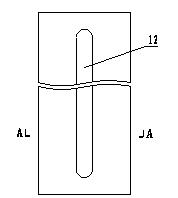

[0018] The vibrating plate adopts a traditional structure: on the inner wall of the vibrating plate 2, there is a spiral track with a width slightly larger than the width of a single nut, and an electromagnet 8 is arranged on the lower part of the vibrating plate. When the electromagnet 8 drives the vibrating plate 2 to vibrate, the material discharged from the hopper 1 The nuts that slide into the vibrating plate 2 move in the same direction along the spiral track, and finally enter the profiling tube 7 in sequence. In order to keep the nut in the same posture when it enters the profiling tube 7, four barriers for adjusting the posture of the nut are arranged in the vibrating plate 2: the first barrier is set on the second circle of the helical track, and the barrier The block is used to lay the upright nuts flat; the second block is set in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com