Jacking transplanting machine

A transplanter and jacking technology, applied in the field of conveyors, can solve the problems of high air pressure requirements, easy inclination of guide posts, easy failures, etc., to ensure horizontal consistency, reduce design volume, and reduce electronic components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

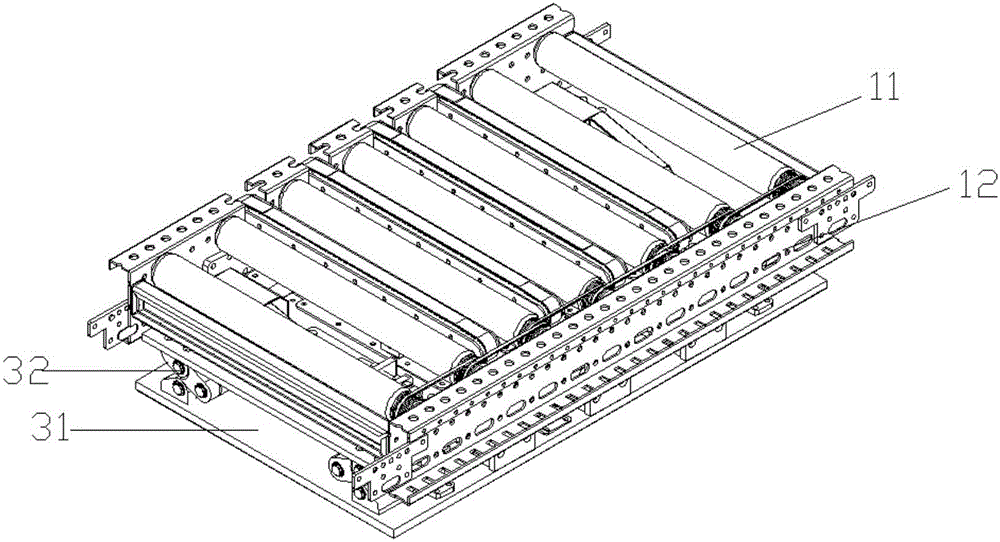

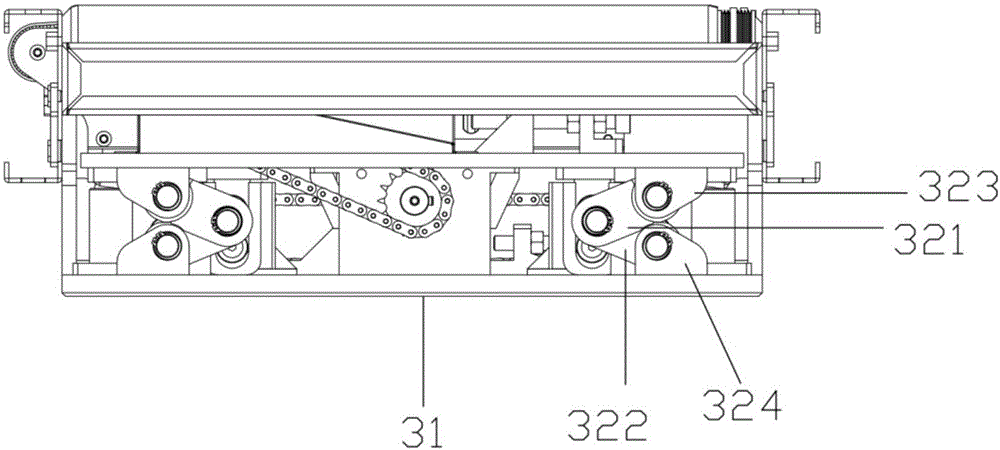

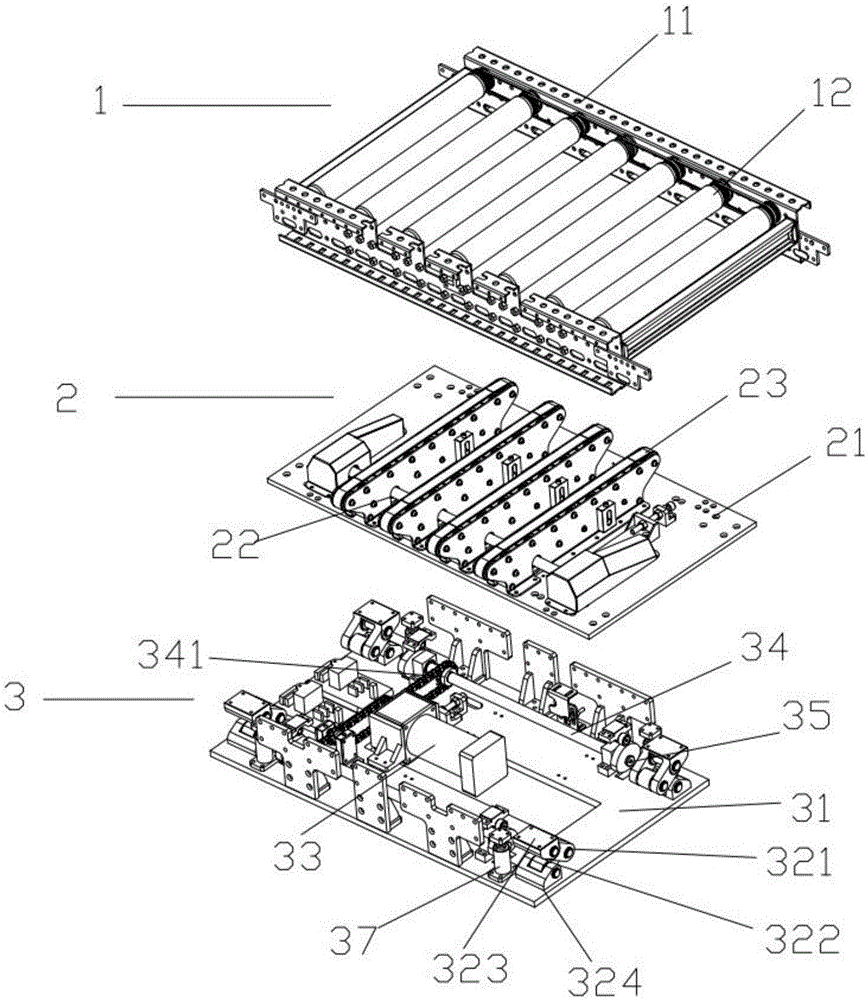

[0023] refer to Figure 1 to Figure 4 As shown, a jacking transplanter of the present invention includes: a first conveying part 1, a second conveying part 2 and a jacking part 3; the first conveying part 1 is consistent with the conveying direction of the main line, and the second conveying part Part 2 intersects with the conveying direction of the main line, and the two are in a vertical direction during the transfer and conveying work;

[0024] The first conveying part 1 comprises: several conveying rollers 11 and side frames 12; the conveying rollers 11 are fixed on the side frames 12 at equal intervals, and the distance between two conveying rollers 11 axes is usually 120mm, according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com