Pin-forming mold for integrated circuits

A technology for forming molds and integrated circuits, which is applied in the field of integrated circuit compression molding, can solve the problems of mandrel and roller sticking, changing back to sliding friction forming, and rollers cannot roll, etc., to achieve convenient molding size, improve quality, and avoid sticking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

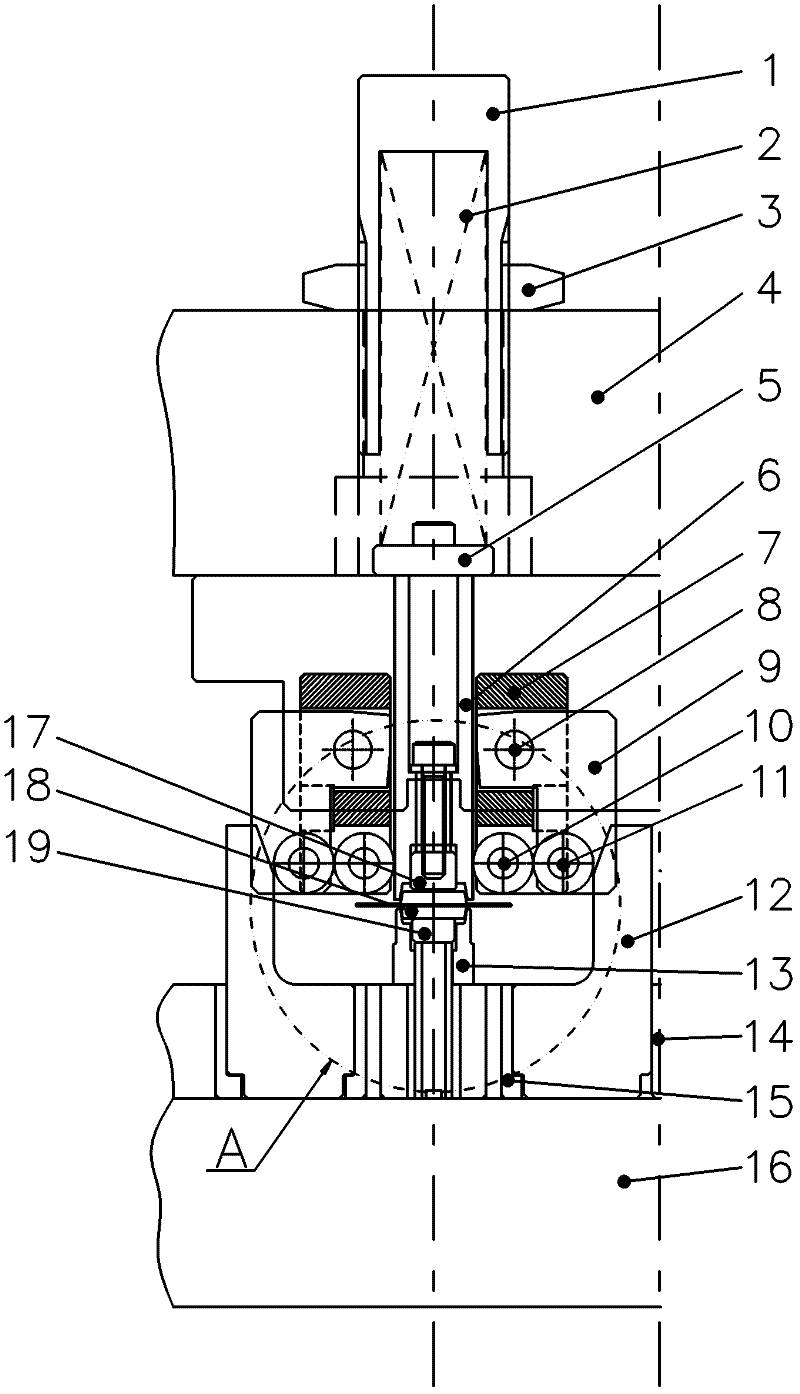

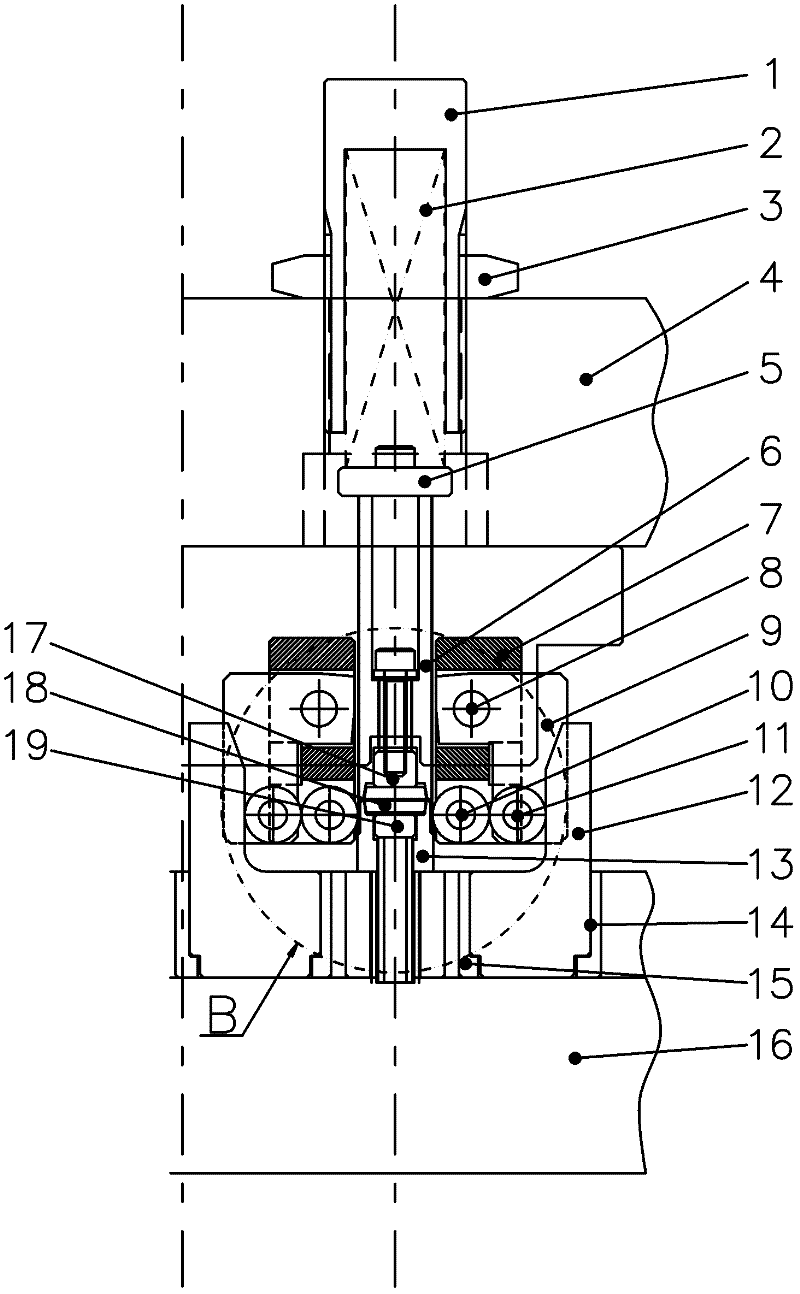

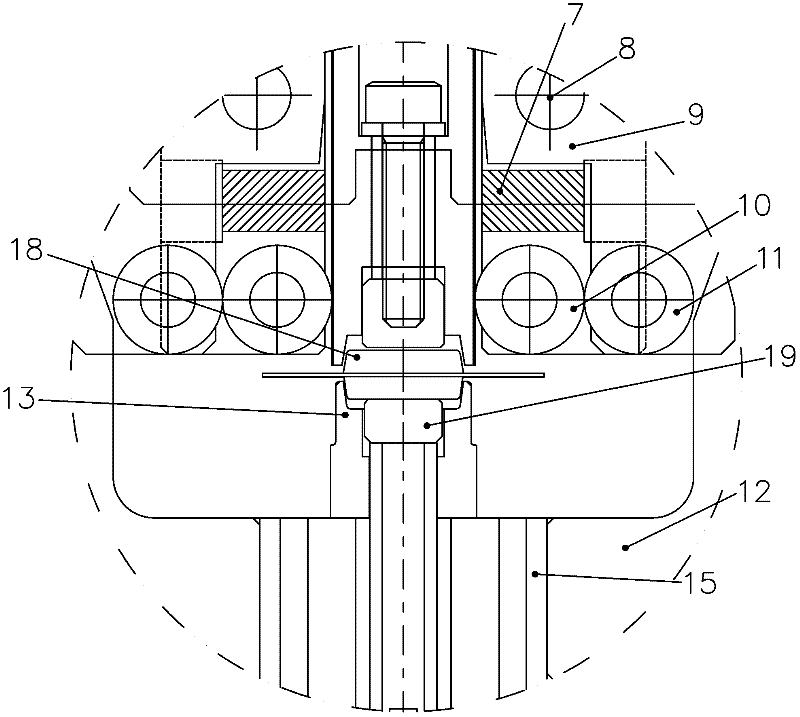

[0030] Such as Figure 1~4 As shown, a pin molding die for integrated circuits, this mold includes a fixing device for pressing the product 18 and its pins to be formed, and the two sides of the fixing device are provided with pins for forming the pins A conjugate roller device, the side of the conjugate roller device away from the fixing device is provided with a wedge device for guiding the conjugate roller device to work.

[0031] Preferably, the fixing device includes a forming concave film 13 for erecting the product to be formed 18, and also includes a pressing block 17 pressed against the upper side of the product to be formed 18 and a top material against the lower side of the product to be formed 18 Block 19; the binder block 17 is penetrated in the binder plate 6, and the binder block 17 forms a sliding fit with the binder plate 6; the lower side of the binder plate 6 is provided with a leg pressed against the pin ; The upper side of the pressing plate 6 extends upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com