Pipe segment diameter adjustable hard rock tunneling machine adopting double-layer supporting mode and construction method thereof

A technology of hard rock roadheader and construction method, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve problems such as not solving the problem of stuck shield from the root, and achieve saving time and labor, reasonable structural design, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

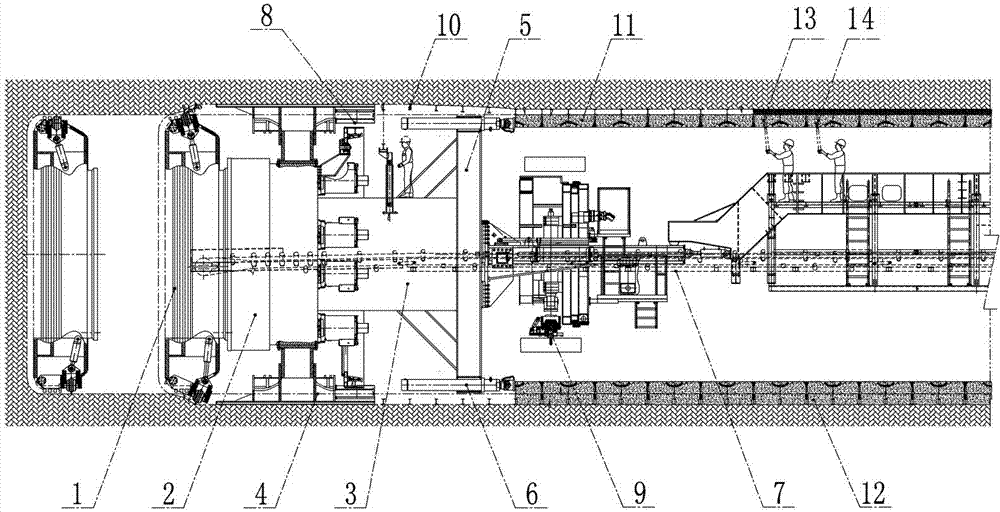

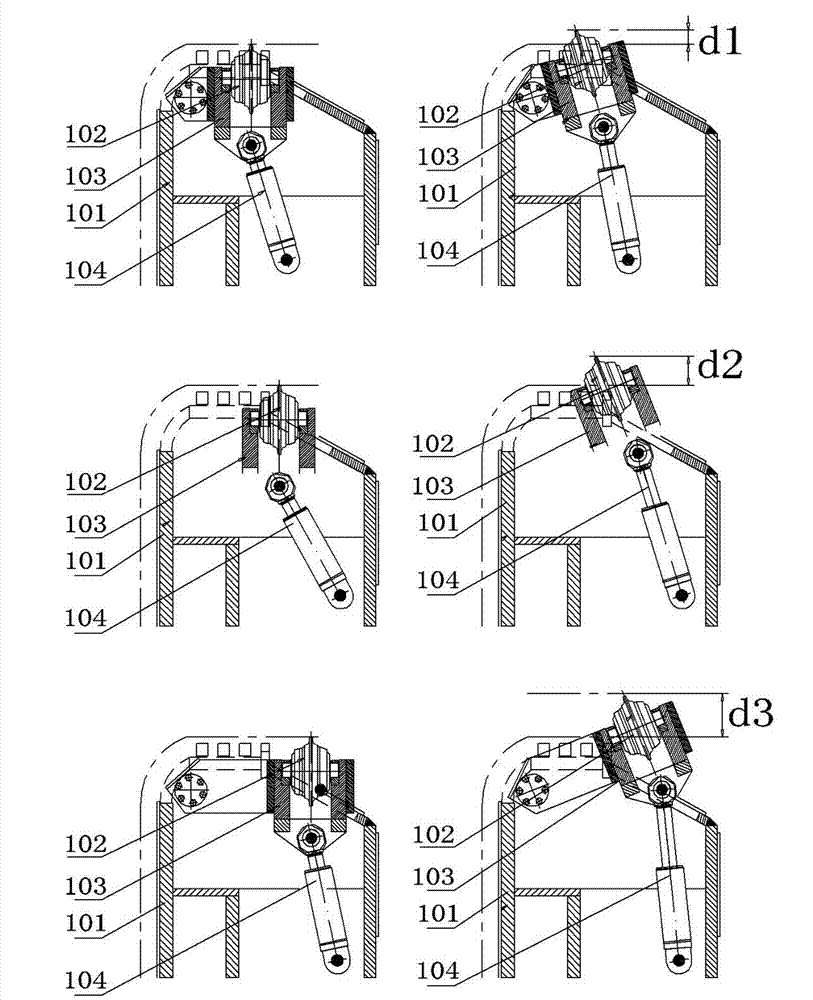

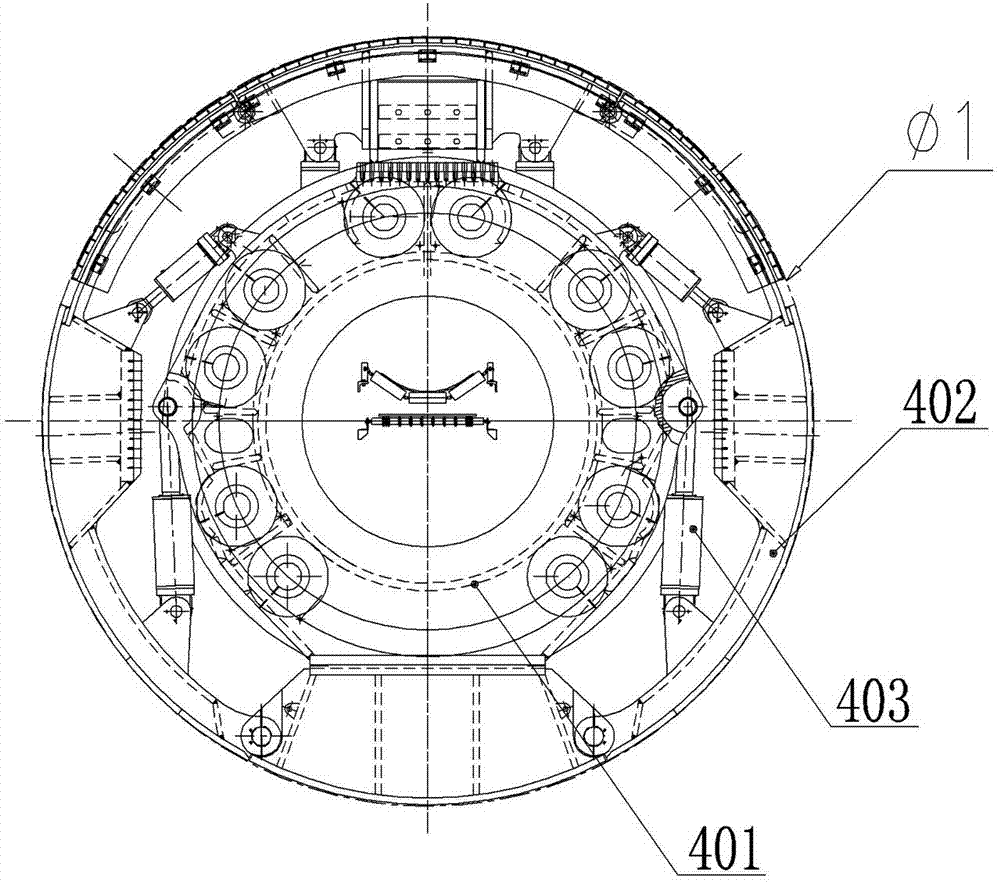

[0030] Embodiment one: see Figure 1-Figure 4 , a hard rock tunneling machine with double-layer support and variable segment diameter, including an expansion cutterhead 1, a main drive 2 for driving the expansion cutterhead 1 to excavate, and a main girder connected to the rear end of the main drive 2 3. Temporary support and radially retractable circular shield 4. The connecting box 5 and the sliding girder 7 that support the main propulsion cylinder 6 and the sliding girder 7 are arranged behind the main girder 3, and a flexible steel arch is arranged on the main girder 3 Frame assembly machine 8, the sliding girder 7 is provided with a segment assembly machine 9, the expanded excavation cutterhead 1 includes an expanded excavation cutterhead body 101 and a different angle around the expansion cutterhead body 101 A series of digging hobs 102, the said hob 102 is set on the digging cutter body 101 through the digging hob seat 103, the hob seat 103 is hinged with the digging c...

Embodiment 2

[0036] Embodiment two: see Figure 1-Figure 4 , a construction method using a hard rock roadheader with double-layer support and variable segment diameter, for the tunnel construction section with large deformation of surrounding rock and easy collapse, prefabricated by flexible steel arch frame and rigid concrete The construction is carried out in the double-layer support method with the mutual cooperation of the segments. The diameter of the excavation section is φ1=8000mm when the non-expanding excavation is required. When the double-layer support is required, the diameter of the expansion excavation is increased to φ2=8600mm to meet the double-layer support standard. As an example, it includes the following steps:

[0037] ①Through advanced detection technology, the rock and soil stress in front of the excavated tunnel support face is detected and analyzed, and it is determined that the pre-construction section needs double-layer support work;

[0038] ②Adjust the 3 expan...

Embodiment 3

[0043] Embodiment three: see Figure 1-Figure 4 , the method of this embodiment is aimed at another situation existing in the tunnel excavation process in the second embodiment, that is, in step ①, when the detection and analysis results show that the deformation of the surrounding rock in the pre-construction section is small, no double-layer When the support operation requires only a small amount of excavation to satisfy the stress release of the surrounding rock, the expansion of the excavation cutter head can be reduced by adjusting the expansion cylinder of the expansion cutter head, and at the same time, the prefabricated segment Appropriately adjust the outer diameter size, and directly assemble the prefabricated segments, so that there is a certain size difference between the tunnel excavation diameter and the outer diameter of the prefabricated segments and form a stress relief cavity, which serves as the surrounding rock convergence point Need space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com