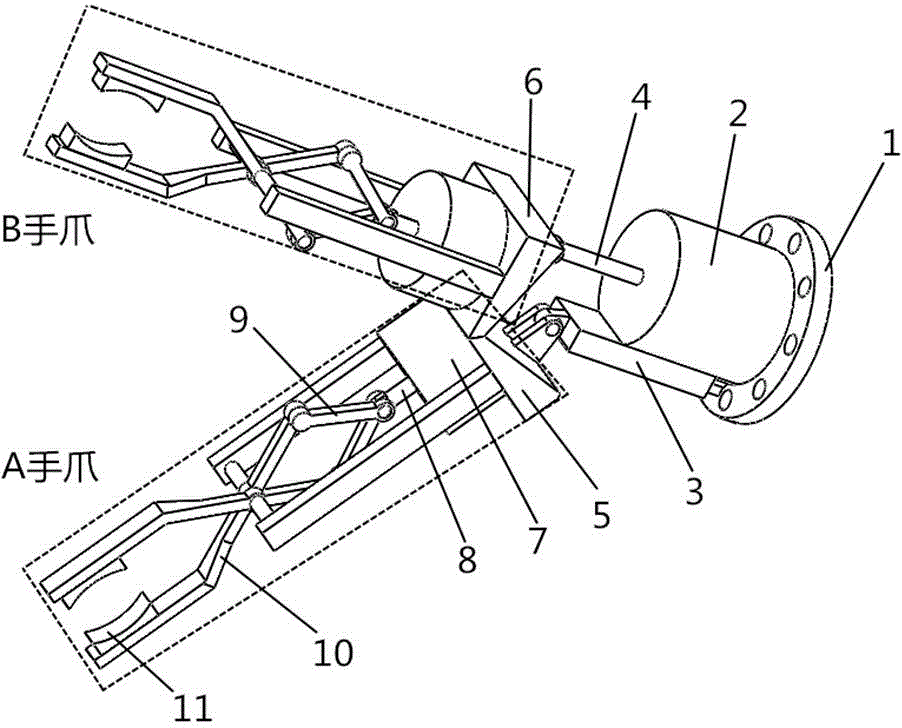

Grabbing pneumatic connecting rod arm with double-paw structure

A connecting rod arm and gripper technology, which is applied in the field of pneumatic connecting rod arm for grasping, can solve the problems of natural cooling time influence, prolonging the processing cycle, affecting production efficiency, etc. The effect of improving production tact and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The use workflow of the present invention is as follows:

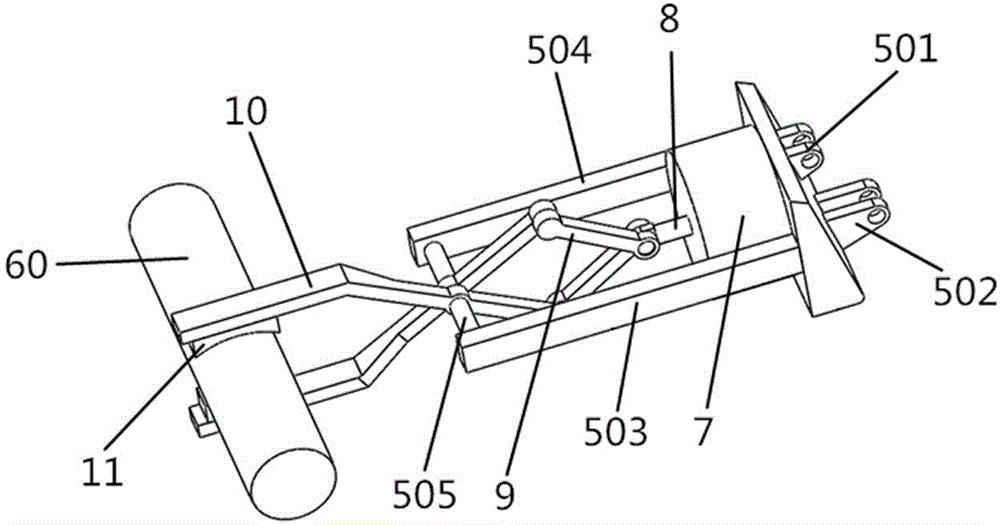

[0030] see figure 1 and 2 . When the claw is clamping the part, the cylinder extension rod extends to push the scissor linkage mechanism to move, so that the opening of the left and right fingers gradually increases, and the opened left and right fingers move to the part, and the cylinder extension rod shrinks , the opening of the left and right hands gradually decreases, and the workpiece is clamped.

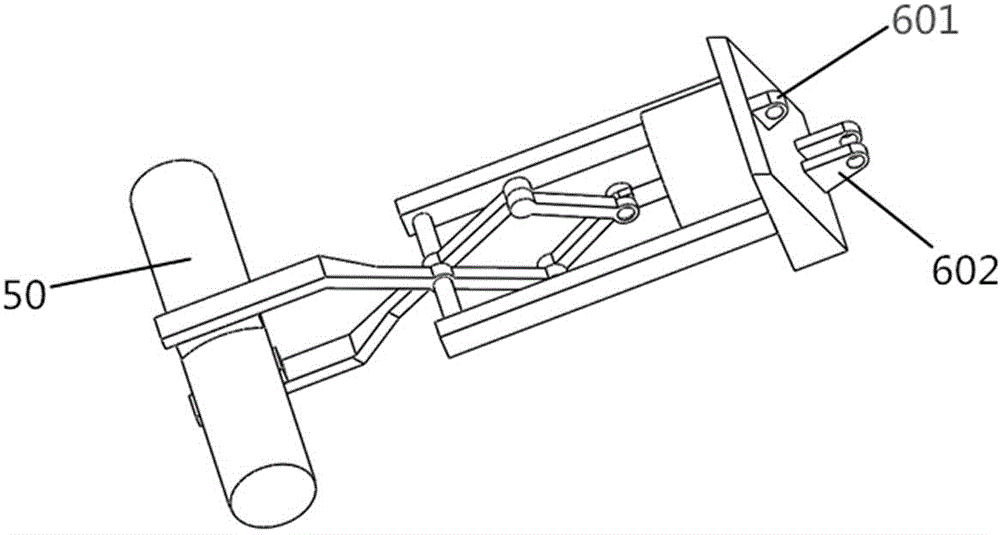

[0031] see figure 1 and 4 . During parts processing, the claw of A grasps the part and waits. After the processing is completed, the extension rod 4 of the claw indexing cylinder is stretched out until the claw of B is level. B claws grab the processed parts.

[0032] see figure 1 and 5 . Claw rotates cylinder extension rod 4 and retracts until A claw is horizontal, and now the axis of the connecting hole connected at three places of the base is still an equilateral triangle.

[0033] During the movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com