A double-furnace sealed and heat-insulating structure for a spherical wafer automatic production line

An automatic production line and wafer cake technology, which is applied in applications, food ovens, baked hollow foods, etc., can solve the problems of waste of heat resources, large energy consumption, and long baking time, so as to reduce the impact of high temperature and prolong the baking time. The effect of service life and energy-saving output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

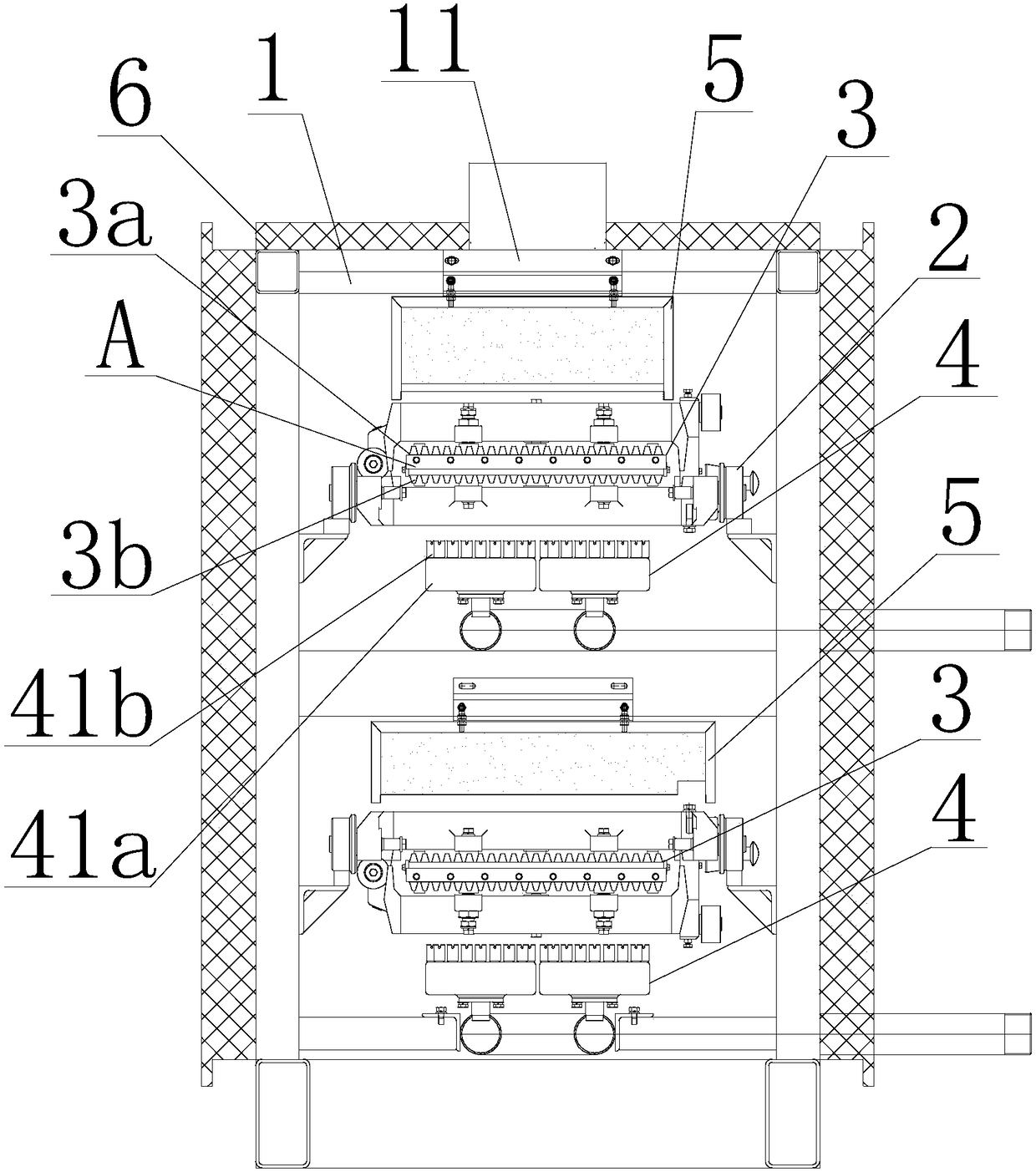

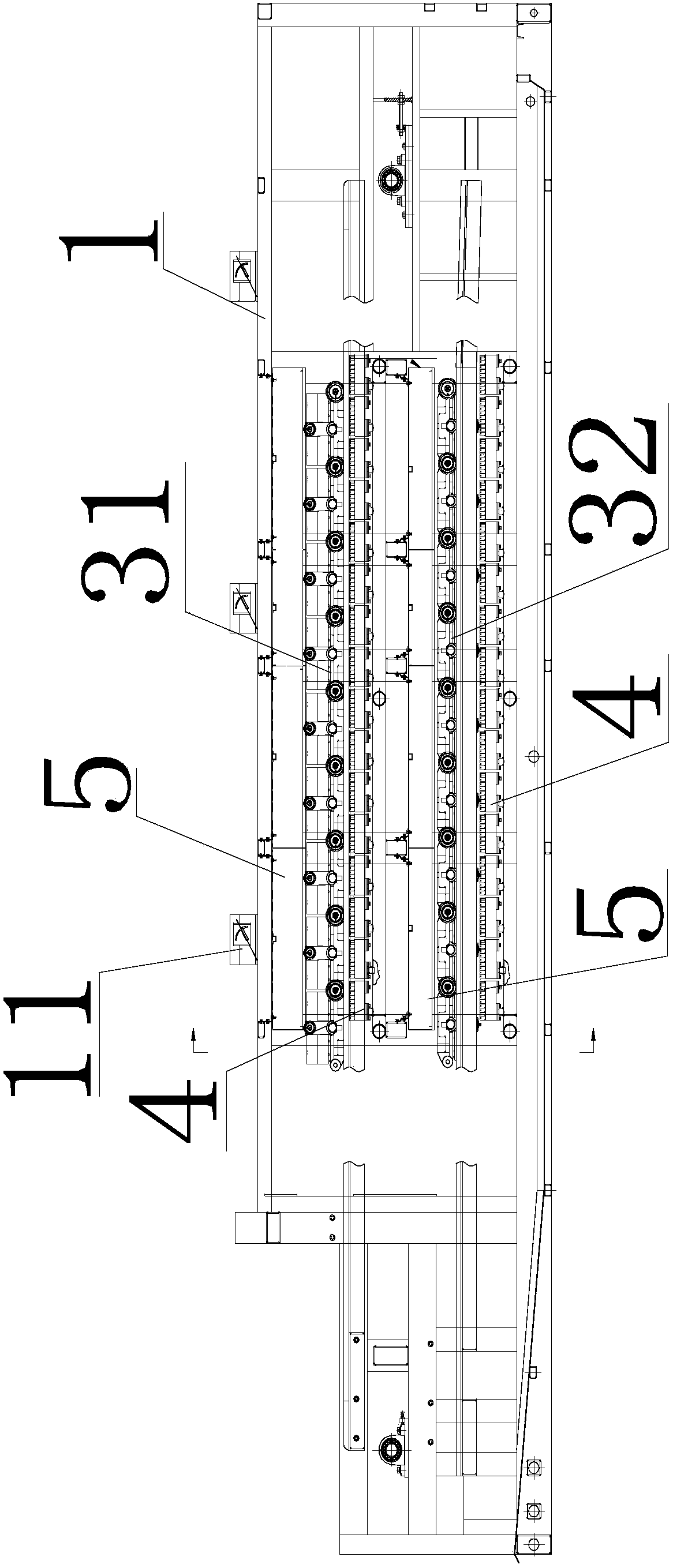

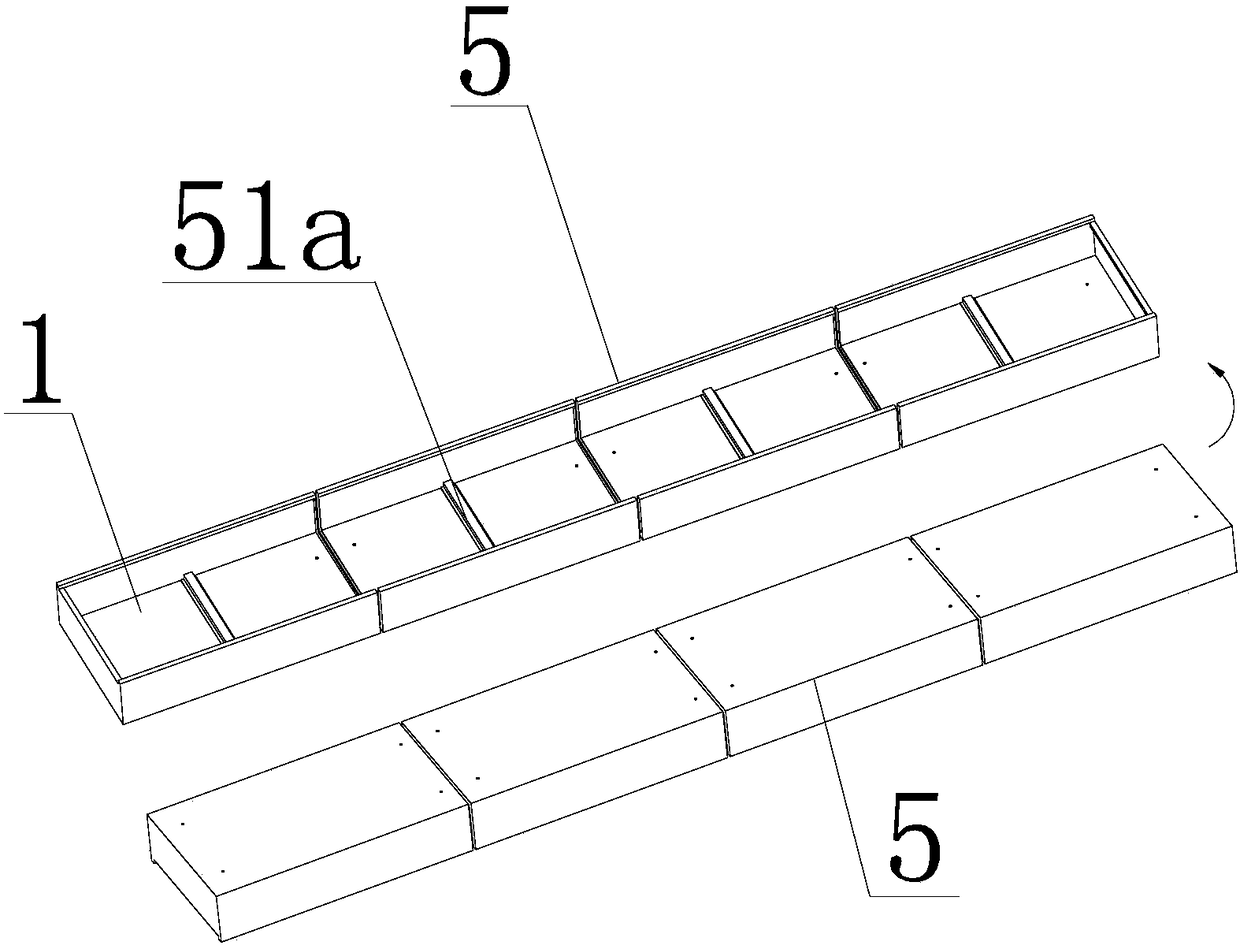

[0018] Such as Figure 1 to Figure 3 As shown, the spherical wafer automatic production line of the present invention uses a double-furnace sealed heat preservation structure, including a closed box 1, and a heat dissipation outlet 11 is arranged on the top of the closed box 1, wherein a circulating transmission is arranged in the closed box 1 chain 2, a plurality of molds 3 are arranged along the running track on the circular transmission chain 2 to form upper and lower mold conveying lines 31, 32, and below the upper and lower mold conveying lines 31, 32 are respectively provided with 4 pairs of baking ovens. The molds 3 are baked, and heat preservation covers 5 are provided above the upper and lower mold conveying lines 31 and 32 to reflect the baking hot air flow back to each mold 3; a plurality of molds 3 are equidistantly arranged and fixed on the circulating transmission chain 2 The mold 3 includes an upper template 3a and a lower template 3b, and the upper and lower te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com