A method to effectively improve the thermal stability of nisin

A thermal stability and emulsion technology, applied in fermentation, food science, food preservation, etc., can solve the problems of bacteriostatic range and pH application range not improving, and achieve thermal stability protection, simplified processing procedures, and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

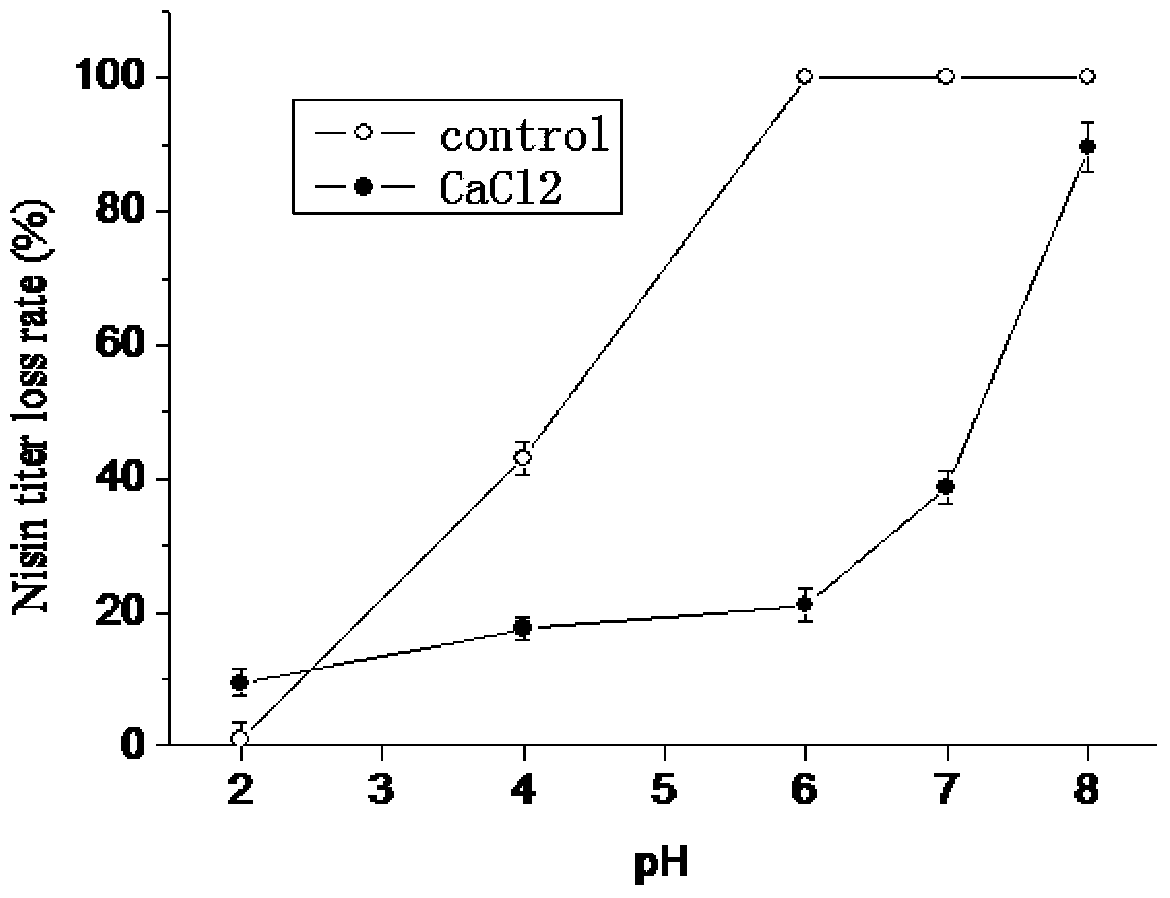

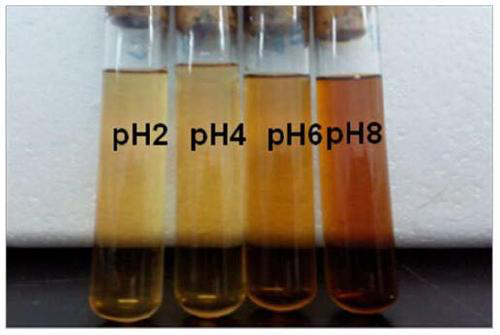

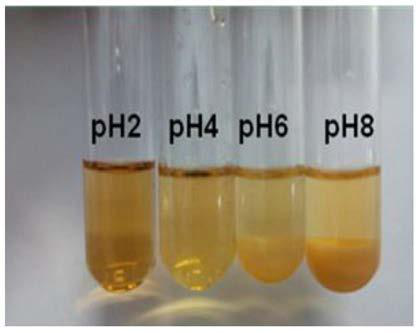

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0042] A method for effectively improving Nisin thermal stability, the steps are as follows:

[0043] (1) After the fermentation is finished, adjust the pH of the fermentation broth to 2.0-2.5 with HCl, then raise the temperature of the fermentation broth to 75-90°C for 20-30 minutes, and then quickly cool it down to room temperature;

[0044] (2) The fermented liquid cooled to room temperature in step (1) is firstly filtered with a filter cloth or membrane to remove large particles, bacteria and incompatible substances to obtain the primary filtrate, and then the primary filtrate is subjected to microfiltration treatment with a microfiltration membrane with a pore size of 0.45 μm , using the ultrafiltration system with a molecular weight cut-off of 1KDa to carry out ultrafiltration on Nisin to remove small molecular substances from the filtrate after microfiltration, and obtain the purified Nisin retentate;

[0045] (3) Pass the Nisin retentate after ultrafiltration and purif...

Embodiment approach 2

[0049] The difference between this embodiment and specific embodiment 1 is: the addition method of calcium chloride

[0050] At the beginning of fermentation, add 0.1-1.0% (g / 100ml) calcium chloride, mix evenly, transfer 1%-6% seed solution, and culture at 30-37°C for 8-15 hours. In the purification process of calcium chloride fermented liquid, first use filter cloth or membrane to filter out large particles, bacteria and incompatible substances to obtain the primary filtrate, and then perform microfiltration on the primary filtrate with a microfiltration membrane with a pore size of 0.45 μm Treatment, without ultrafiltration and nanofiltration desalination operations. Other steps and parameters are the same as those in Embodiment 1. After the same treatment as step (5) of Embodiment 1, the Nisin emulsion is finally obtained.

Embodiment approach 3

[0052] The difference between this embodiment and specific embodiment 1, 2 is: the addition mode of calcium chloride is:

[0053] In the 3rd to 14th hour of the fermentation process, 0.1 to 1.0% (g / 100ml) calcium chloride is added to the fermentation medium, after mixing evenly, the static cultivation is continued until the fermentation is completed. Other steps and parameters are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com