Energy-saving bread maker

A technology of bread machines and bread barrels, which is applied in the direction of roasters/barbecue grids, kitchen utensils, household utensils, etc. It can solve the problems of interlayer overheating, increased cost, low energy efficiency, etc., to reduce the external size, prolong the service life, The effect of improving the energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

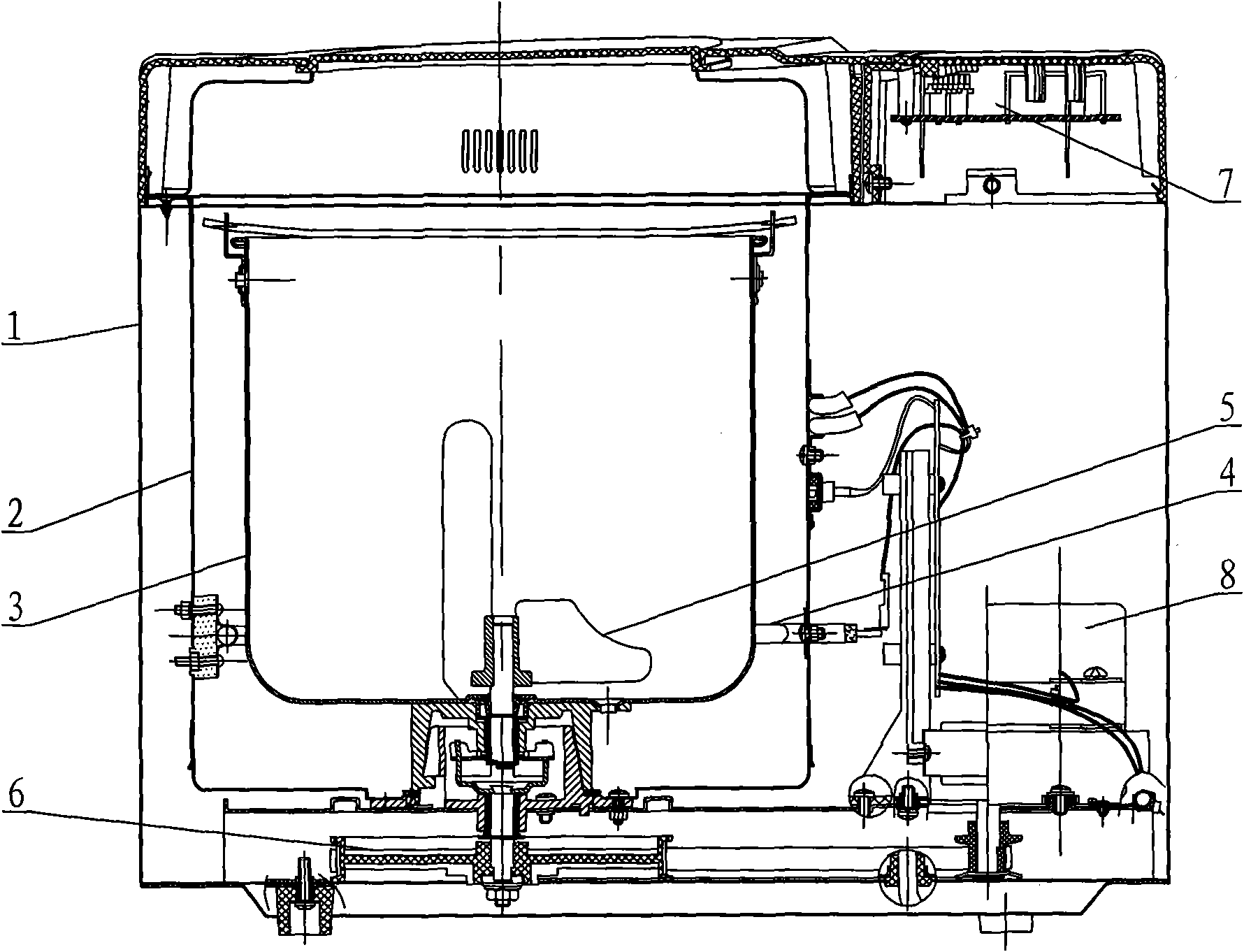

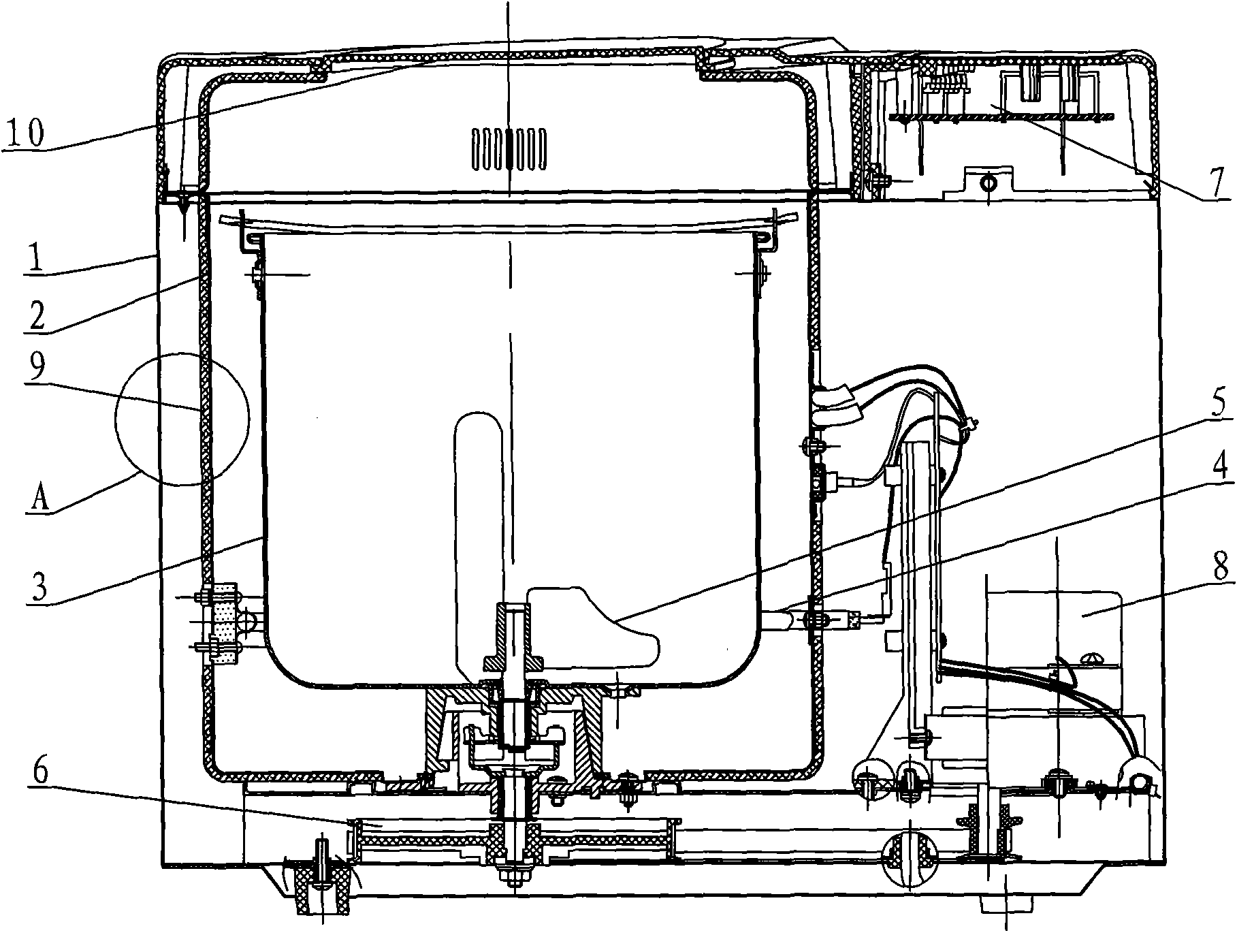

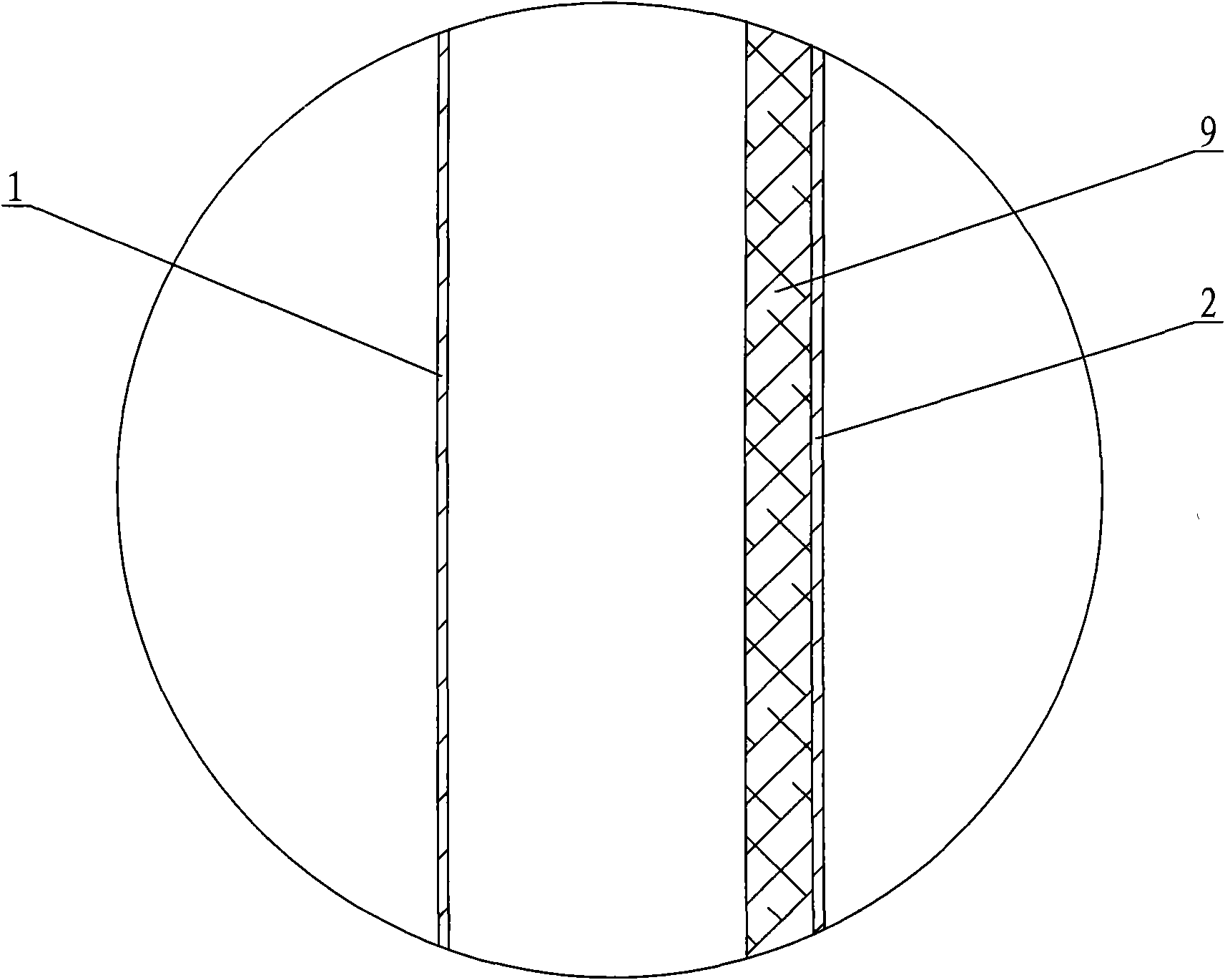

[0013] see Figure 2-Figure 3 , the energy-saving bread machine includes a casing 1, an upper cover 10 is arranged on the left side of the upper part of the casing, a controller 7 is arranged on the right side, a motor 8 is arranged below the casing 1 corresponding to the controller, and an upper cover 10 is arranged between the casing 1 There is a baking room 2, a bread bucket 3 is installed in the baking room, electric heating tubes 4 are evenly distributed between the bread bucket and the baking room 2, a stirring rod 5 is installed at the bottom of the bread bucket 3, and the stirring rod is connected to the motor 8 through the transmission system 6 , the outside of the baking chamber 2 is covered with a thermal insulation material layer 9. The thermal insulation material layer 9 is a non-metallic material with thermal insulation and heat reflectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com