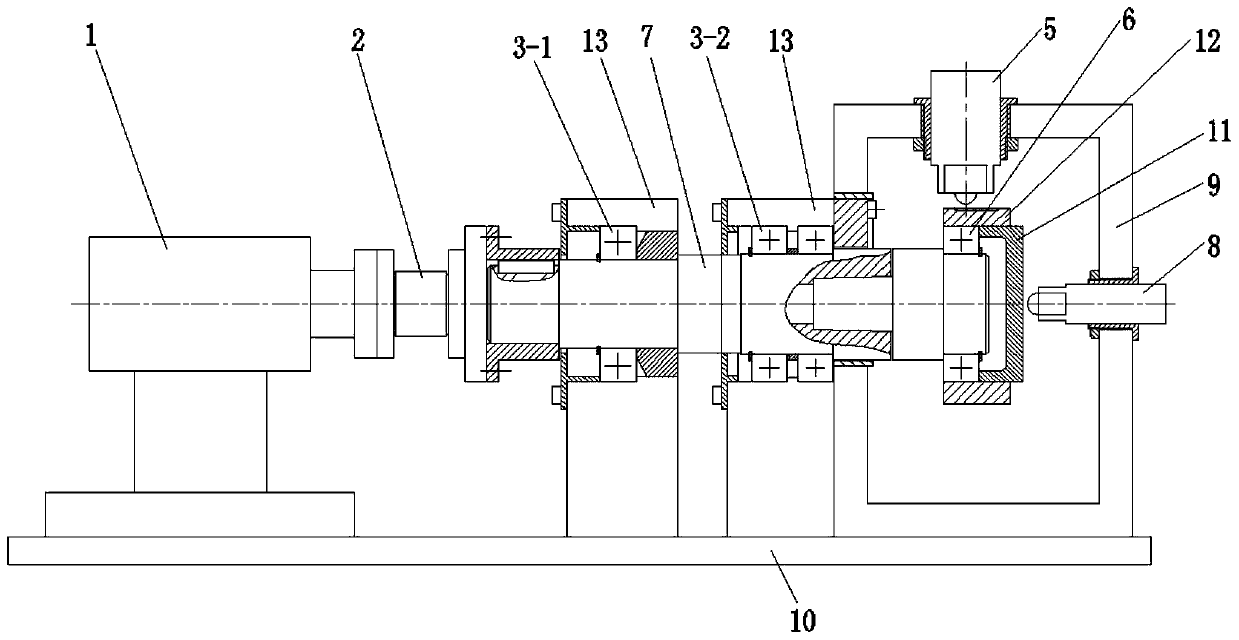

Device and method for testing performance of cold-hot cavity short-distance isolated heavy-load ultrahigh-temperature bearing

A bearing performance and testing device technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as incomplete calculation of life and reliability, uncertainty of bearing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

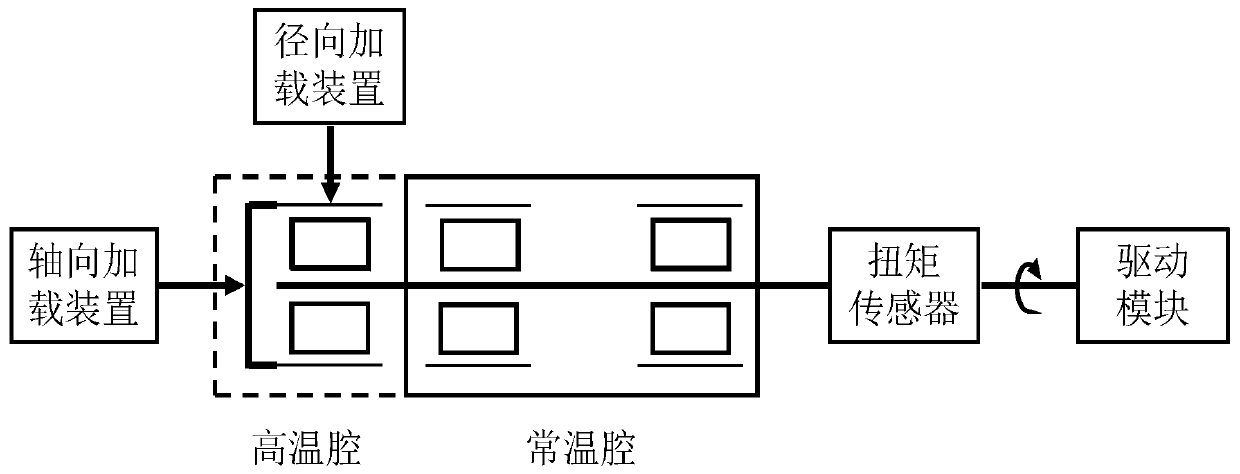

Method used

Image

Examples

Embodiment 1

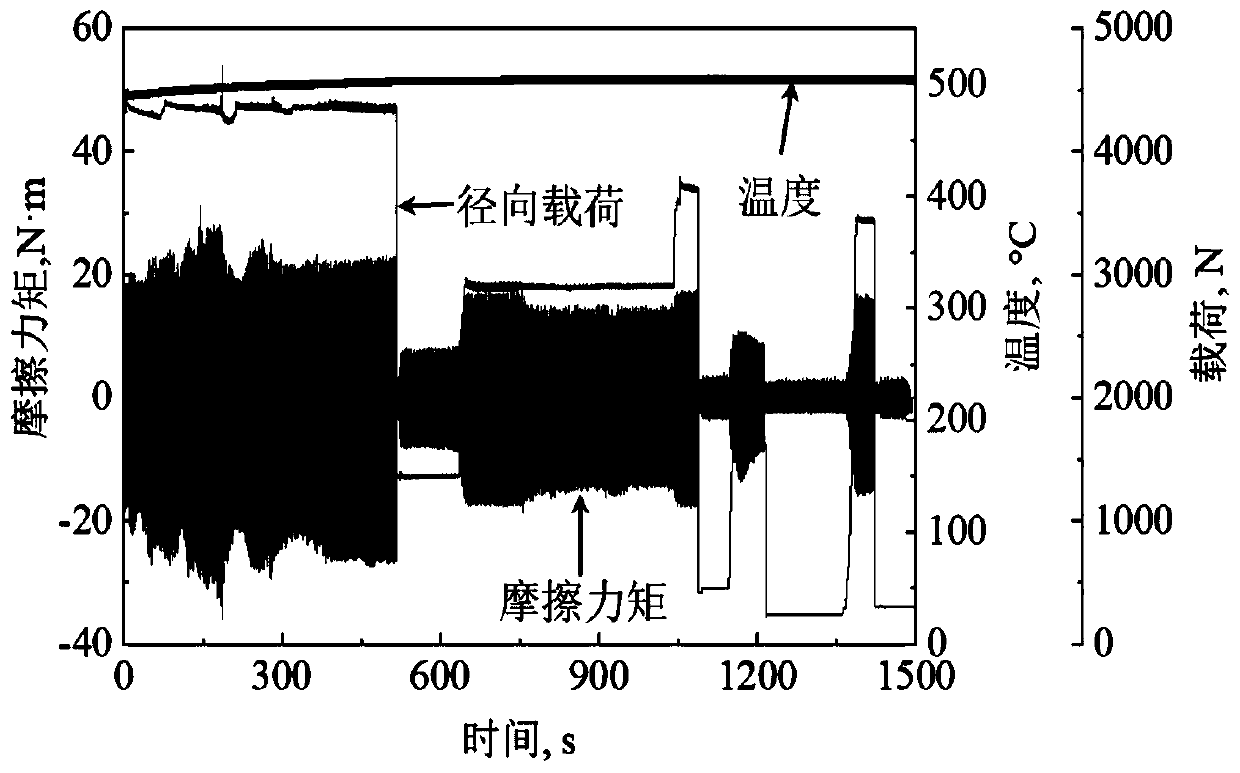

[0035] Example 1: The tested bearing 6 is 32018X, the test temperature is room temperature -600°C, the radial load is 20-60kN, the axial load is 10-25kN, the motion mode of the bearing is reciprocating swing, and the swing angular velocity is 600° / s. The friction torque of the test bearing 6 is about 0-230N·m.

Embodiment 2

[0036] Example 2: The tested bearing 6 is 6207, the test temperature is from room temperature to 300°C, the radial load is 50-300N, and the axial load is 100-1150N. The friction torque of the test bearing 6 is about 0-3N·m.

Embodiment 3

[0037] Example 3: The tested bearing 6 is 71910C, the test temperature is room temperature -500°C, the radial load is 3-7.3kN, the axial load is 0.3-0.5kN, the bearing motion mode is reciprocating swing, and the swing angular velocity is 120° / s. The friction torque of the tested bearing is about 0-7N·m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com