Intelligent temperature control type high-precision burr-proof stamping mold

An intelligent temperature control, stamping die technology, applied in the field of stamping equipment, can solve the problems of burrs, sheet cracks, increased stamping gap, etc., to delay the aging of the die, prolong the service life, and improve the processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

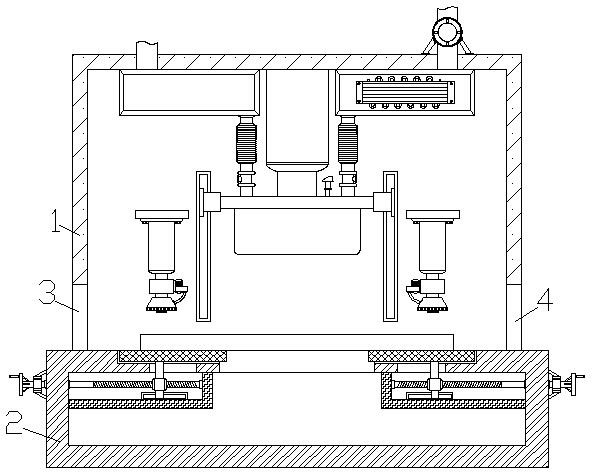

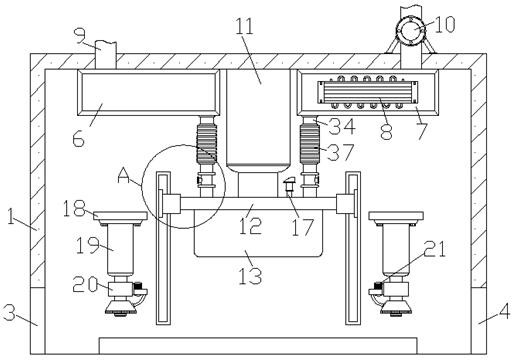

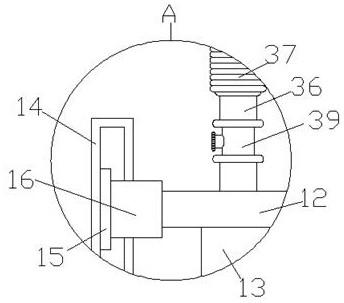

[0044] Such as Figure 1-8 As shown, an intelligent temperature-controlled high-precision anti-burr stamping die includes an upper mold base 1 and a lower mold base 2, the bottom of the upper mold base 1 is fixedly connected to the top of the lower mold base 2, and the inner walls on both sides of the upper mold base 1 are respectively opened. There is a material inlet 3 and a material outlet 4, the material inlet 3 and the material outlet 4 are used for feeding and discharging, the front of the upper mold base 1 is provided with a PLC controller 5, and the PLC controller 5 is used to control the water pump 10 , the switch of air pump 21, condenser 8 and electronic valve 39, the first water tank 6 and the second water tank 7 are fixedly installed on the inner top wall of the upper mold base 1, and are used for cooling water. The second water tank 7 A condenser 8 is arranged on the front side to exchange heat for the water in the second water tank 7, reduce the temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com