Processing system for amorphous alloy magnetic core belt material of mutual inductor

An amorphous alloy and processing system technology, applied in the field of amorphous alloy transformer magnetic core strip processing system, can solve the problems of high maintenance workload and cost, burns and waste of collection operators, and achieve production reliability and safety High performance, reduced aging rate, and reduced waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

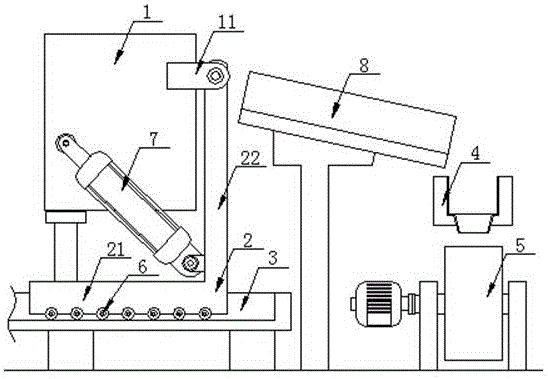

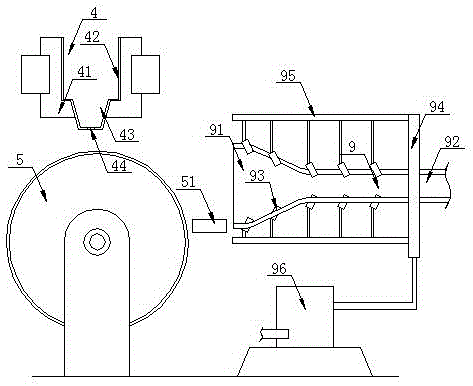

[0018] refer to figure 1 with figure 2 , figure 1 with figure 2 It is a structural schematic diagram of a specific embodiment of the present invention.

[0019] Such as figure 1 with figure 2 As shown, an amorphous alloy transformer magnetic core strip processing system includes an amorphous alloy melting furnace 1, a melting furnace movable support 2 arranged at the bottom of the amorphous alloy melting furnace 1, and a movable support 2 arranged at the bottom of the melting furnace. The melting furnace sliding guide rail 3 at the bottom of the support 2, the amorphous alloy pouring container 4 arranged at one end of the melting furnace sliding guide rail 3, the amorphous alloy strip cooling roll 5 arranged at the bottom of the amorphous alloy pouring container 4, the The amorphous alloy melting furnace 1 is fixedly arranged on the movable support 2 of the melting furnace, and the bottom of the movable support 2 of the melting furnace is provided with some movable rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com