Vertical reduction jar

A reduction tank, vertical technology, applied in the field of vertical reduction tank, can solve the problems affecting the service life of the reduction tank, potential safety hazards, structural damage around the weld, etc., to achieve the effect of convenient maintenance, prolonging the service life and reducing the impact of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

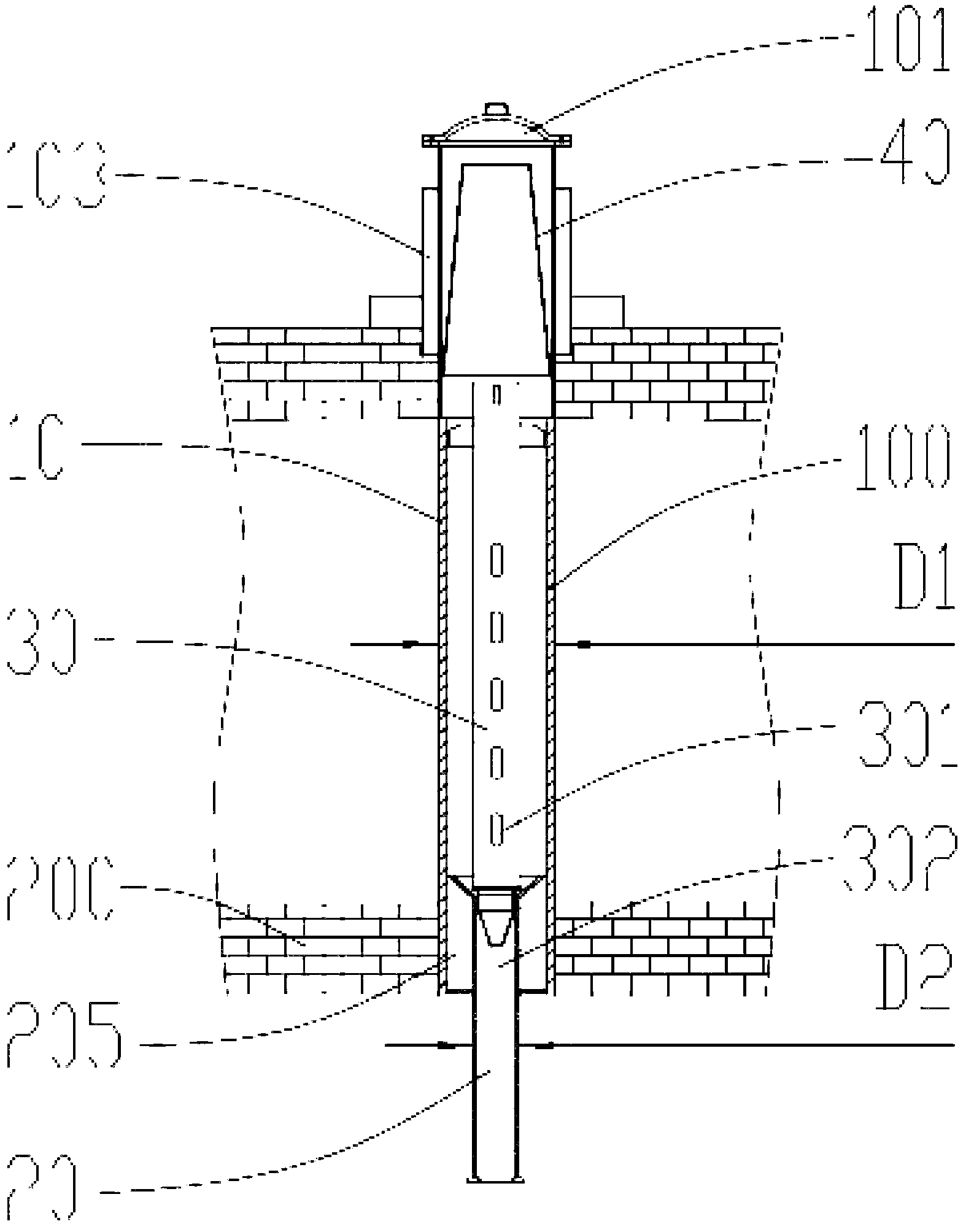

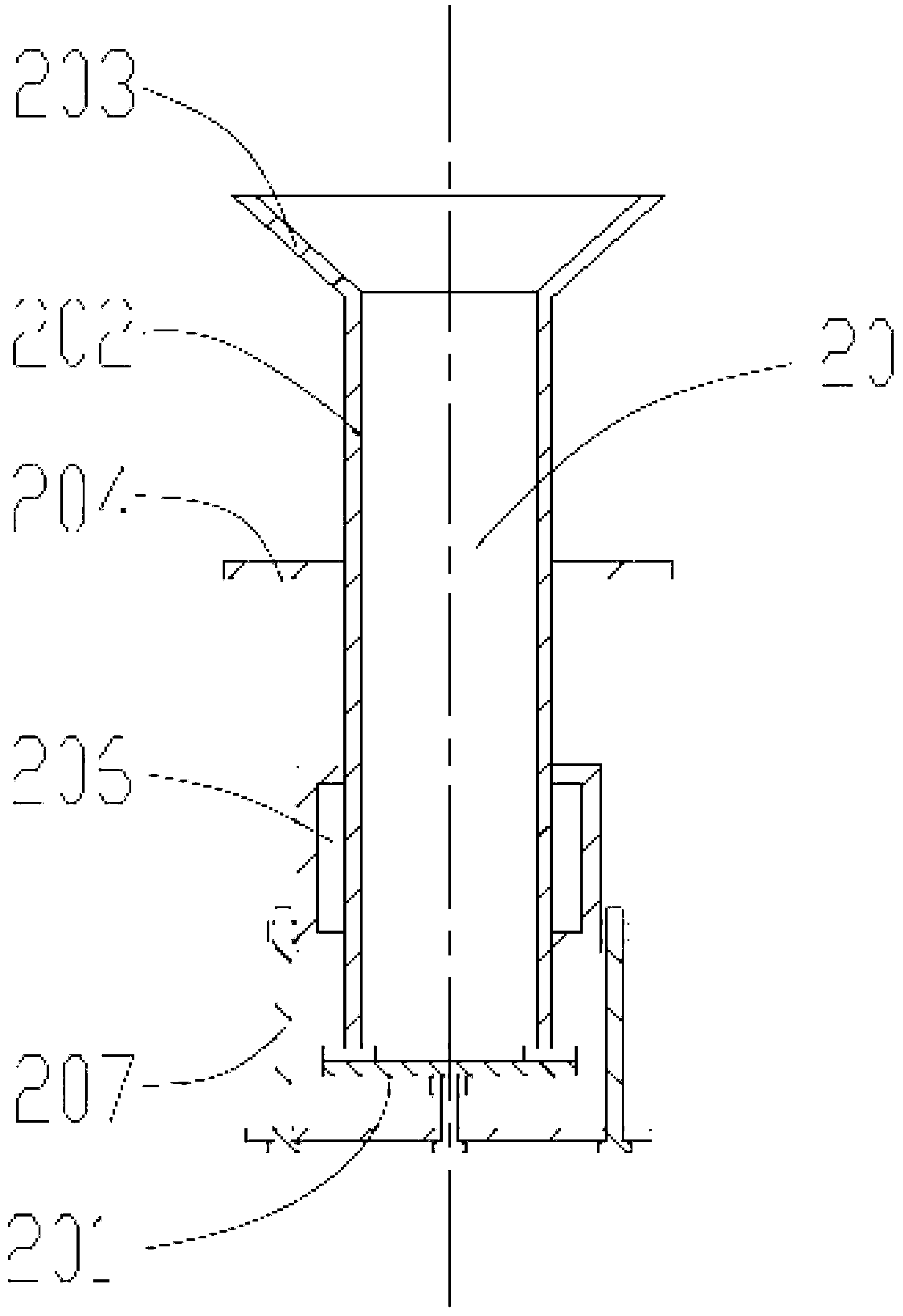

[0019] see figure 1 with figure 2 , the vertical reduction tank 100 of the present invention is further specifically described below in conjunction with the accompanying drawings as follows, figure 1 In order to make the lines clear and concise, the lower cooling water jacket and the lower sealing cover of the discharge part are omitted. For details, please refer to figure 2 .

[0020] The vertical reduction tank 100 of the present invention runs through the furnace (not shown) surrounded by the partition wall 200, and includes a main tank body 10, an upper sealing cover 101 for sealing the upper edge of the main tank body 10, and a discharge part 20. , the lower sealing cover 201 sealing the lower edge of the discharge part 20 and the central pipe 30 pierced in the vertical reduction tank 100 . The main tank 10 has a first diameter D1, and the discharge part 20 includes a discharge cylinder 202, a bowl 203 connected to the upper edge of the discharge cylinder 202, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com