No-axle spiral conveyer

A shaftless screw conveying and casing technology, applied in packaging and other directions, can solve the problem that bearings and reducers are easily affected by high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

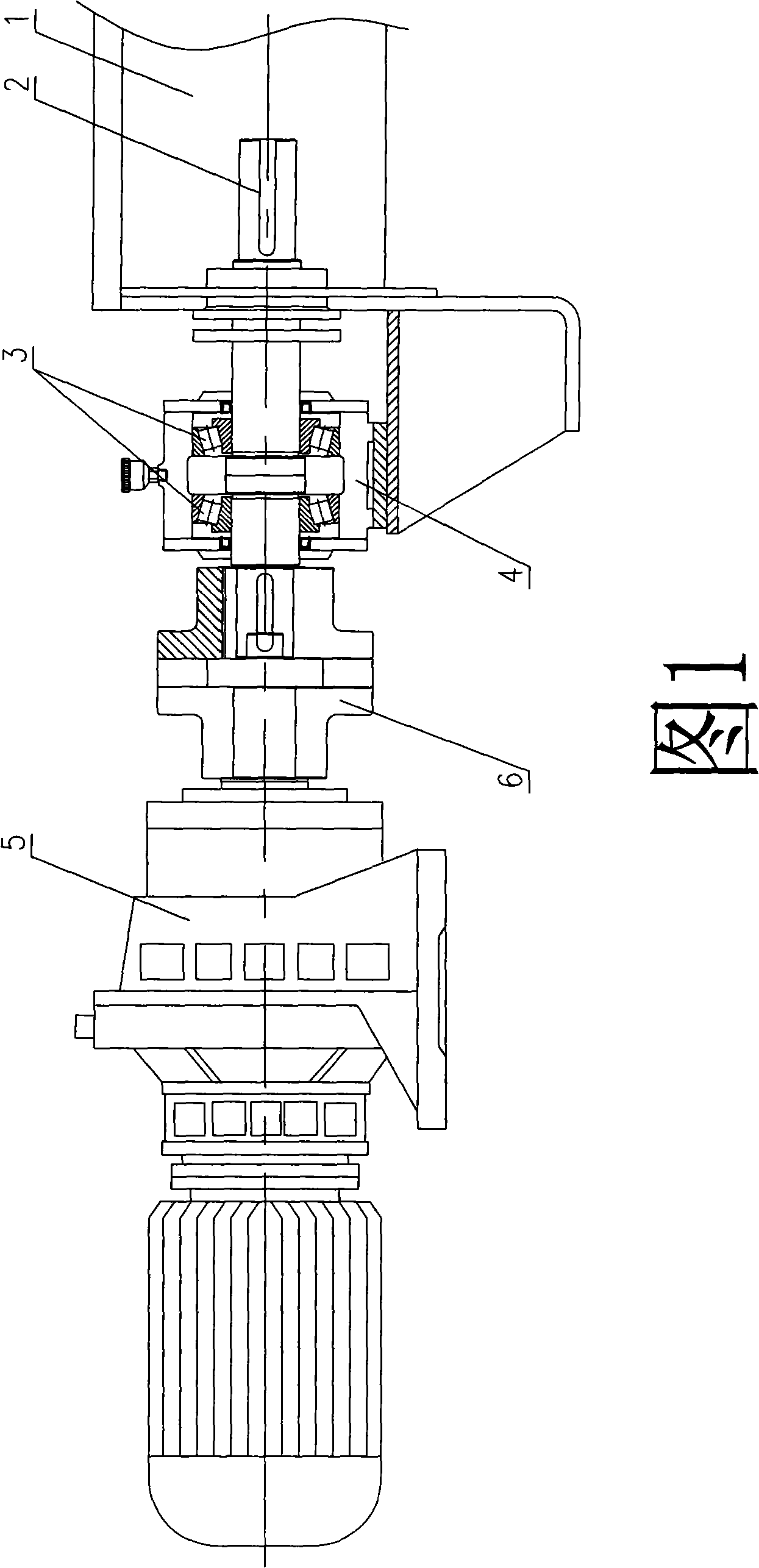

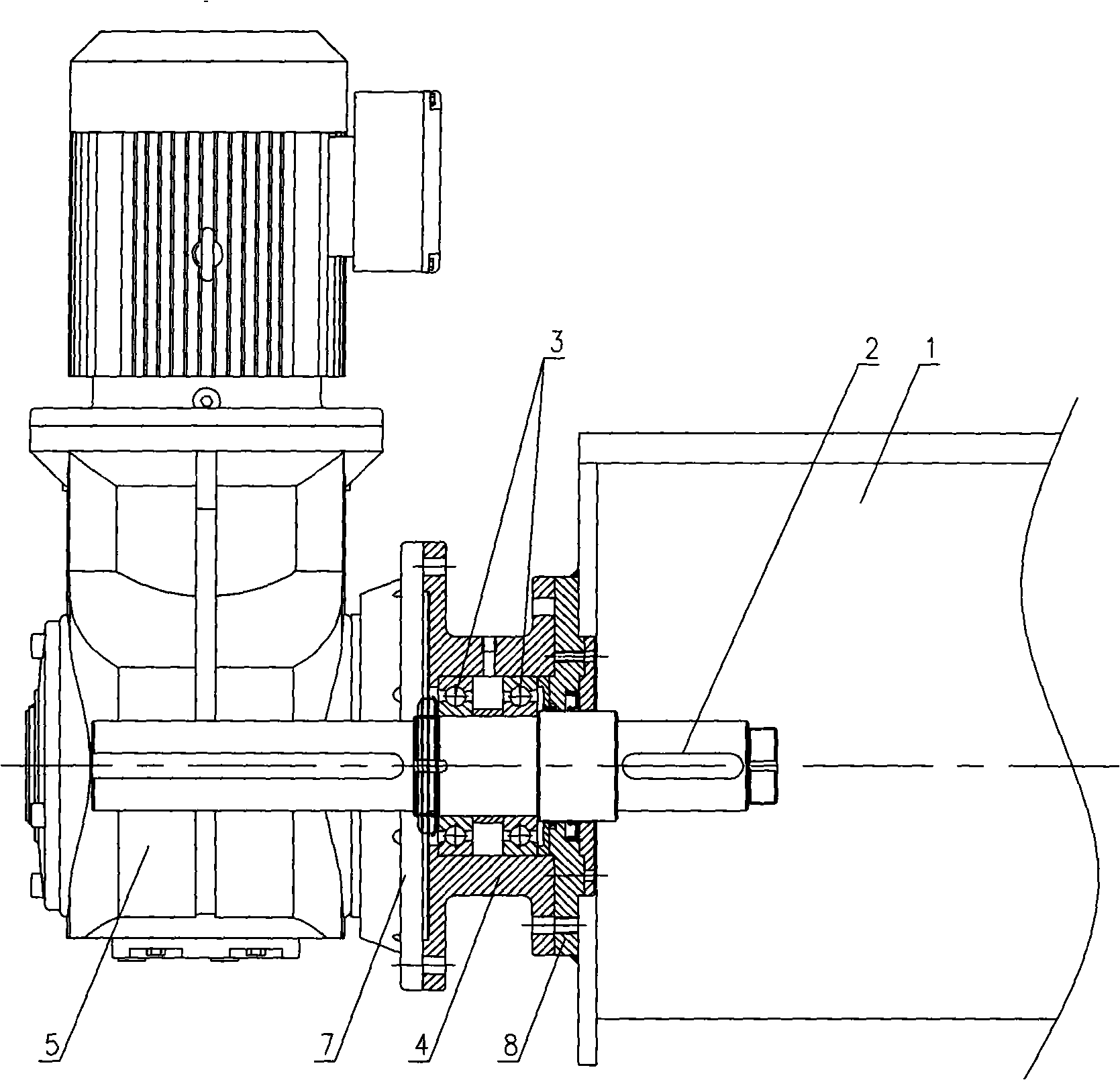

[0011] A shaftless screw conveyor of the present invention comprises a casing 1, a transmission shaft 2 pierced on the casing 1, a head bearing 3 installed in a bearing seat 4 and a reducer 5, the head bearing 3 is set On the transmission shaft 2 protruding out of the casing.

[0012] As shown in Figure 1, it is embodiment 1, the transmission shaft 2 and the reducer 5 are connected by a coupling 6, and the head bearing 3 is installed on the transmission shaft 2 outside the casing, wherein the head bearing 3 is a pair For radial roller bearings, there are bearing baffles and oil seals at both ends of the bearing.

[0013] Such as figure 2 Example 2 is shown, the reducer 5 is connected to the bearing seat 4 through the flange 7, and the bearing seat 4 is connected to the casing 1 through the flange 8, wherein the head bearing 3 is a pair of radial ball bearings. The structure also has sealing and dust-proof functions, and is suitable for conveying materials with high water con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com