Preparation method of high-temperature resistance degradable PVC tablecloth

A technology of high temperature resistance and PVC film, which is applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc. The effect of small thermoplastic deformation and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

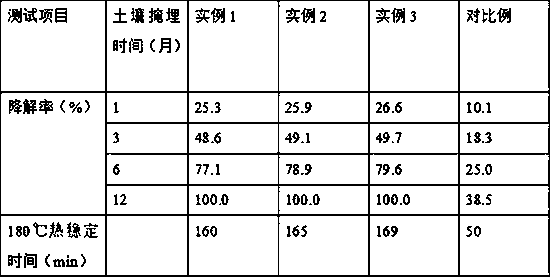

Examples

example 1

[0025]In parts by weight, add 2 parts of sodium lauryl sulfate, 3 parts of polyethylene glycol octyl phenyl ether, 8 parts of sodium bicarbonate and 80 parts of deionized water into the Place the four-necked flask in a water bath, heat up to 80°C, start the stirrer, and stir at a speed of 500r / min until the solid content in the four-necked flask is completely dissolved to obtain a dispersion solvent ; Methyl methacrylate and butyl acrylate are mixed to obtain mixed monomers, and the configuration mass fraction is 40% ammonium persulfate aqueous solution as initiator, by parts by weight, by dropping funnel at a rate of 3mL / min Add 14 parts of mixed monomers to the four-necked flask, stir for 2 minutes, add 2 parts of initiator to the four-necked flask, react for 10 minutes, mix 30 parts of mixed monomers with 4 parts of initiators, To obtain the mixed solution, use the dropping funnel to add the mixed solution dropwise to the four-necked flask at a rate of 5 mL / min, keep the te...

example 2

[0027] In parts by weight, add 3 parts of sodium lauryl sulfate, 4 parts of polyethylene glycol octyl phenyl ether, 9 parts of sodium bicarbonate and 85 parts of deionized water into the Place the four-necked flask in a water bath, heat up to 83°C, start the stirrer, and stir at a speed of 525r / min until the solid content in the four-necked flask is completely dissolved to obtain a dispersion solvent ; Methyl methacrylate and butyl acrylate are mixed to obtain mixed monomers, and the configuration mass fraction is 40% ammonium persulfate aqueous solution as an initiator, and in parts by weight, drop by dropping funnel at 4mL / min Acceleration rate Add 15 parts of mixed monomers to the above-mentioned four-necked flask first, after stirring for 3 minutes, add 2 parts of initiator to the four-necked flask, and after 11 minutes of reaction, mix 31 parts of mixed monomers with 5 parts of initiators, To obtain the mixed solution, use the dropping funnel to drop the mixed solution in...

example 3

[0029] In parts by weight, add 4 parts of sodium lauryl sulfate, 5 parts of polyethylene glycol octylphenyl ether, 10 parts of sodium bicarbonate and 90 parts of deionized water into the Place the four-necked flask in a water bath, heat up to 85°C, start the stirrer, and stir at a speed of 550r / min until the solid content in the four-necked flask is completely dissolved to obtain a dispersion solvent ; Methyl methacrylate and butyl acrylate are mixed to obtain mixed monomers, and the configuration mass fraction is 40% ammonium persulfate aqueous solution as an initiator, in parts by weight, by dropping funnel at a rate of 5mL / min Acceleration rate Add 16 parts of mixed monomers to the four-necked flask, stir for 4 minutes, add 3 parts of initiator to the four-necked flask, and react for 12 minutes, mix 33 parts of mixed monomers with 6 parts of initiator, To obtain the mixed solution, use the dropping funnel to drop the mixed solution into the four-necked flask at a dropping r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com