Fully automatic cutting and forming intelligent control system for brick and tile industry

An intelligent control system, fully automatic technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., to achieve the effect of small fluctuation range, high molding quality and good production adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

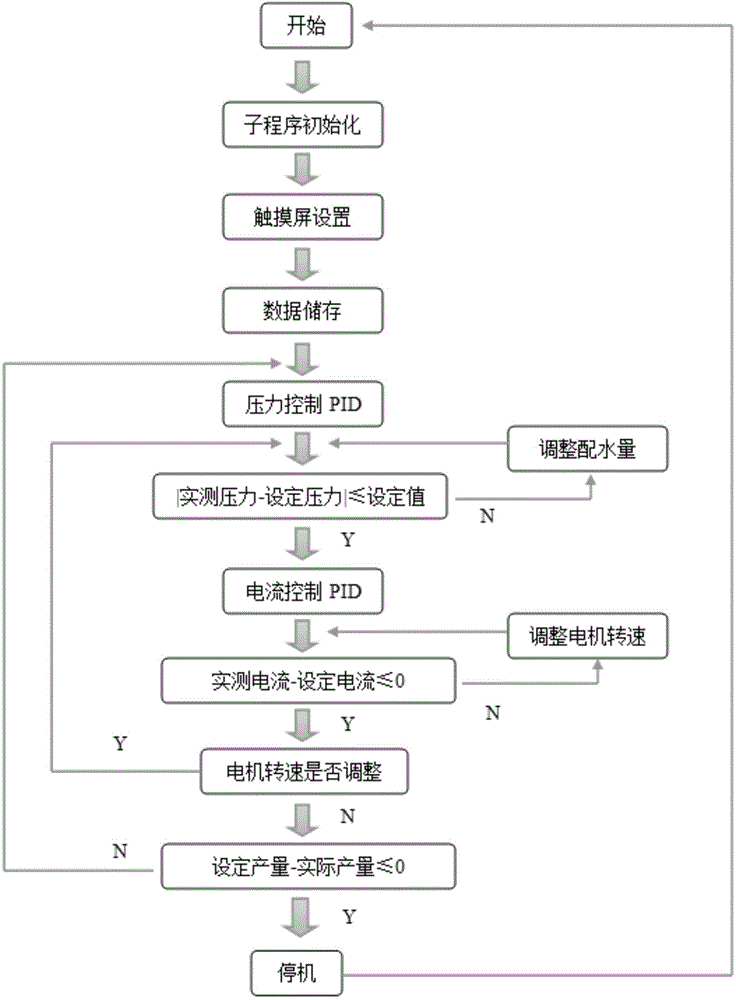

[0042] Example 1: A fully automatic extrusion cutting intelligent control system for the brick and tile industry, including an extruder work control system and an extrusion cutting strip self-diagnosis system. The extruder work control system is composed of an extruder control device and The extruder program control part is composed.

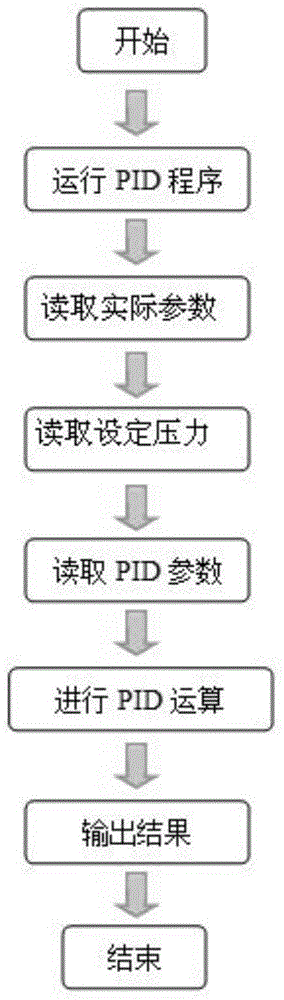

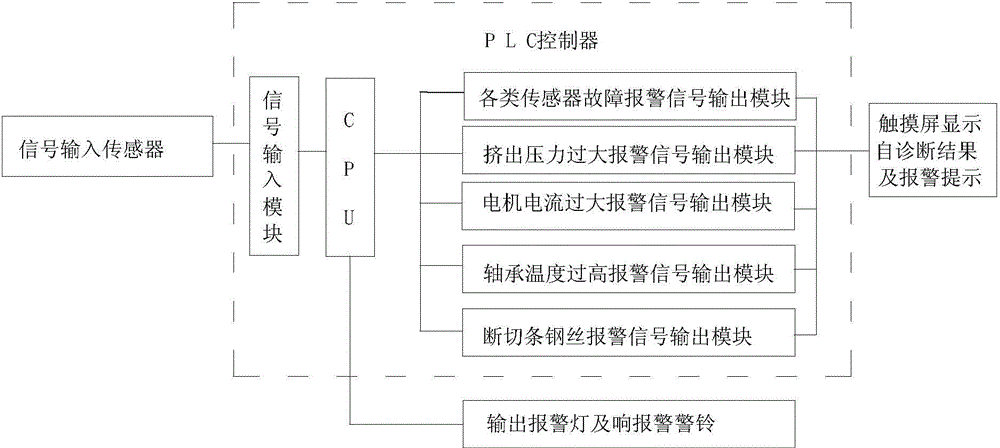

[0043] like Figure 7-Figure 9 As shown, the extruder control device includes a control part, a detection part and an execution part, and the control part includes a control cabinet, and the control cabinet 4 has a PLC controller 44 and a man-machine interface connected to the PLC controller , the human-computer interaction interface is an HMI with a touch screen 41, and the detection part includes an encoder 21 connected to a PLC controller 44 for detecting the speed of the extruder mud bar, and a detection extruder The pressure sensor 110 for the extrusion pressure of the extruder, the current sensor I18 and the current sensor II11 for detect...

Embodiment 2

[0052] Embodiment 2: A fully automatic extrusion cutting forming intelligent control system for the brick and tile industry, including an extruder work control system, an extrusion cutting strip self-diagnosis system, a billet cutting machine work control system and a billet cutter self-diagnosis system, The extruder work control system and the self-diagnosis system for extrusion cutting are the same as those in Embodiment 1.

[0053] The blank cutting machine work control system is composed of a blank cutting machine control device and a blank cutting machine program control part. The blank cutting machine control device includes a control part, a detection part and an execution part. The control part includes a control cabinet The PLC controller inside and the human-computer interaction interface connected with the PLC controller, the detection part includes the mud strip in-position sensor 310 connected with the PLC controller respectively, the pusher head in-position sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com