High-temperature reinforcing refining method of copper-bearing multi-metal material

A high-temperature strengthening and multi-metal technology, applied in the direction of improving process efficiency, can solve the problems of short process cost, high introduction cost, and large flue gas volume, and achieve high comprehensive recovery efficiency, strong raw material adaptability, and production adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

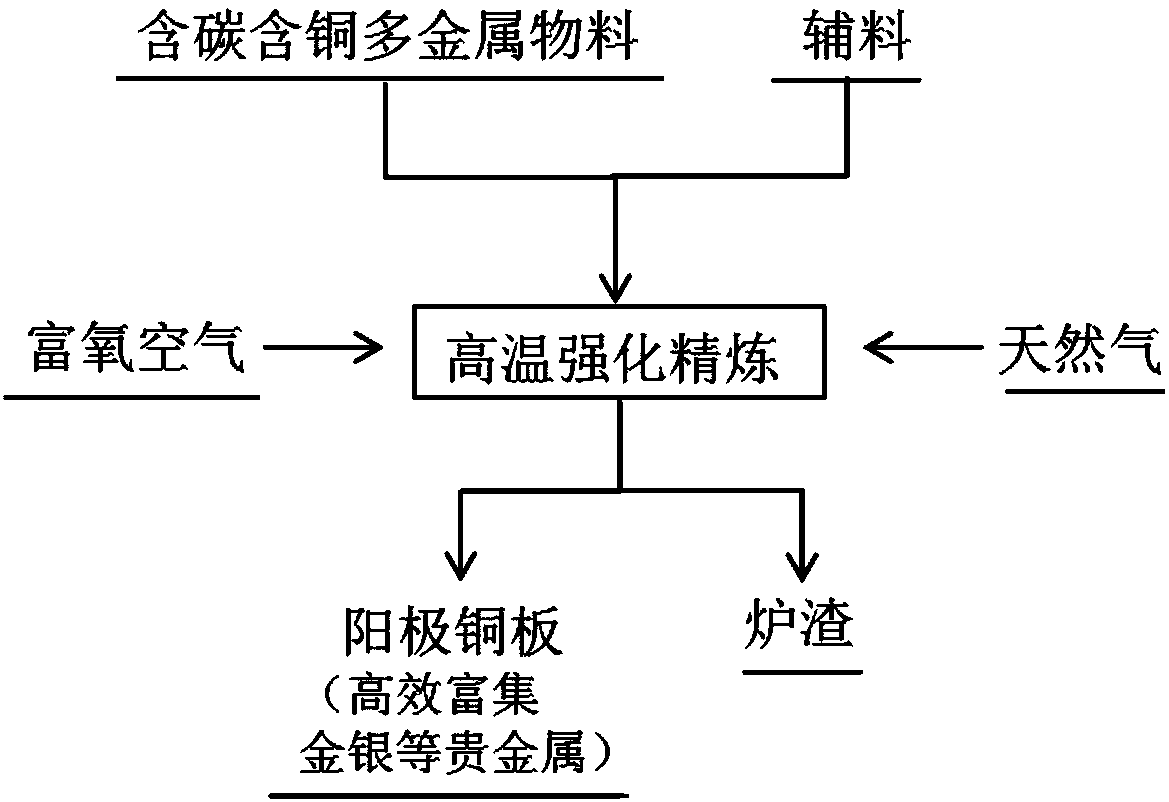

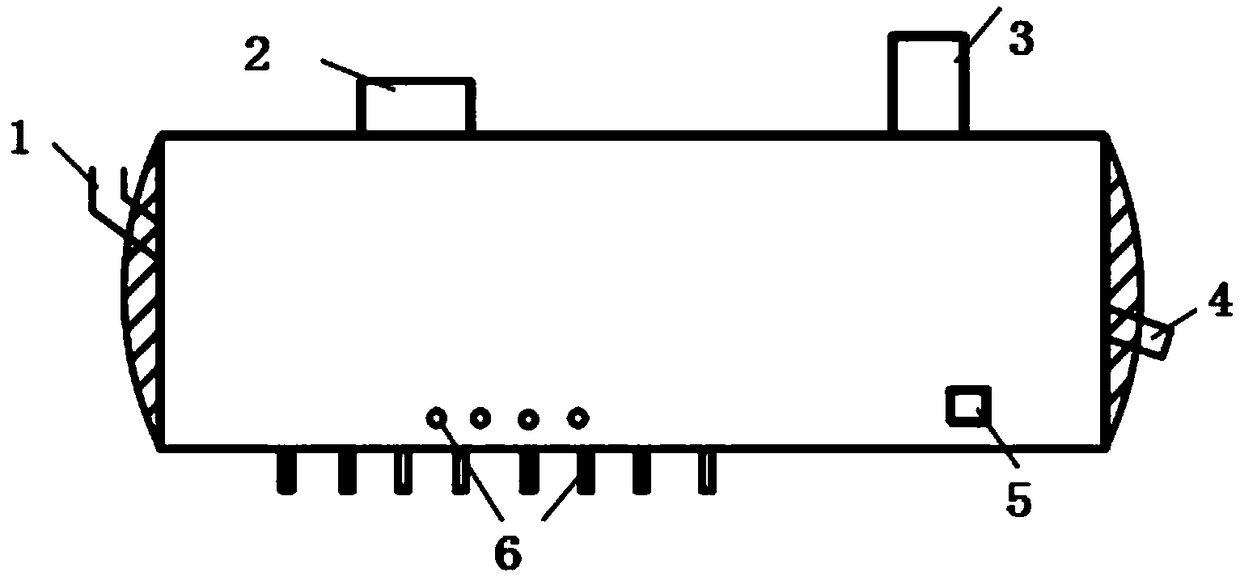

[0042] The refining method of the present embodiment, such as figure 1 As shown, the carbon-containing copper-containing polymetallic materials are put into the high-temperature intensified refining furnace as raw materials, such as figure 2 As shown, the high-temperature intensified refining furnace has a horizontal cylindrical structure, and a circular feeding port 2 is distributed above the furnace body, and secondary materials such as copper-containing carbon-containing multi-metal materials and scrap copper are added through the circular feeding port; A square spare feeding port 1 is arranged on the side end surface, and waste materials such as residual anode and crude copper are added according to the temperature change in the production process; the flue gas is discharged from the flue port 3 and enters the flue gas treatment system; according to the judgment of the liquid level in the furnace, it is respectively passed through the slag discharge port 4 , Copper discha...

Embodiment 2

[0045] The refining method of the present embodiment, such as figure 1 As shown, the carbon-containing copper-containing polymetallic materials are put into the high-temperature intensified refining furnace as raw materials, such as figure 2 As shown, the high-temperature intensified refining furnace has a horizontal cylindrical structure, and a circular feeding port 2 is distributed above the furnace body, and secondary materials such as copper-containing carbon-containing multi-metal materials and scrap copper are added through the circular feeding port; A square spare feeding port 1 is arranged on the side end surface, and waste materials such as residual anode and crude copper are added according to the temperature change in the production process; the flue gas is discharged from the flue port 3 and enters the flue gas treatment system; according to the judgment of the liquid level in the furnace, it is respectively passed through the slag discharge port 4 , Copper discha...

Embodiment 3

[0048] The refining method of the present embodiment, such as figure 1 As shown, the carbon-containing copper-containing polymetallic materials are put into the high-temperature intensified refining furnace as raw materials, such as figure 2 As shown, the high-temperature intensified refining furnace has a horizontal cylindrical structure, and a circular feeding port 2 is distributed above the furnace body, and secondary materials such as copper-containing carbon-containing multi-metal materials and scrap copper are added through the circular feeding port; A square spare feeding port 1 is arranged on the side end surface, and waste materials such as residual anode and crude copper are added according to the temperature change in the production process; the flue gas is discharged from the flue port 3 and enters the flue gas treatment system; according to the judgment of the liquid level in the furnace, it is respectively passed through the slag discharge port 4 , Copper discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com