Swiveling jetting device for removing hydrogen from aluminum melt

A technology of rotary injection and aluminum melt, applied in the field of rotary injection device, can solve the problems of inability to obtain bubbles, insufficient ability of three bosses to crush bubbles, limited stirring ability, etc., to reduce hydrogen absorption and improve hydrogen removal. Efficient and efficient crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

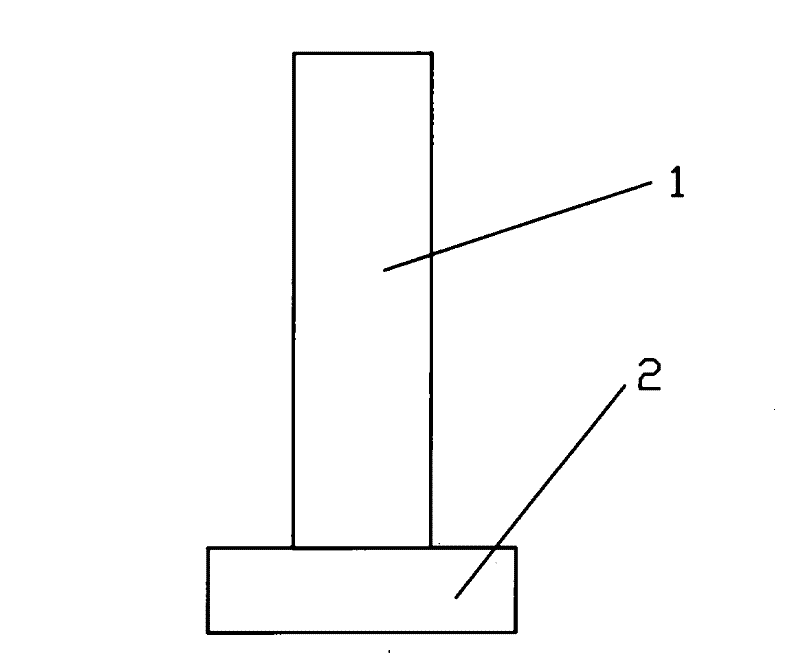

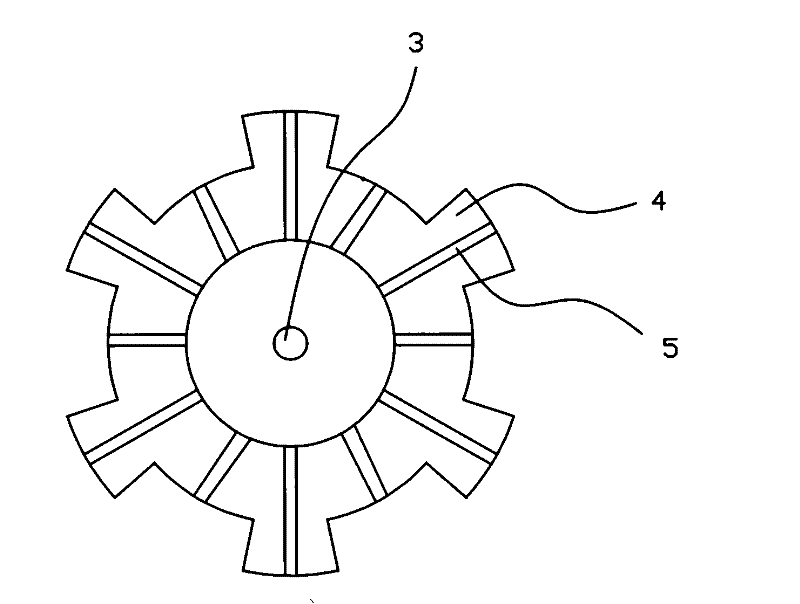

[0031] A rotary blowing device for dehydrogenation of aluminum melt, comprising a gas pipe 1 and a gas nozzle 2, the gas nozzle 2 is threadedly connected to the lower end of the gas pipe 1, and the center of the gas nozzle 2 is provided with an air hole 3 communicating with the gas pipe 1 , the diameter of the gas hole 3 is 5-8mm; 6-10 side teeth 4 are evenly distributed on the circumference of the gas nozzle 2, and each side tooth 4 and the body of the gas nozzle 2 between the adjacent two side teeth 4 form a radial concave Groove 5, the width of the groove 5 is 3-5mm, the gas in the air duct 1 diffuses around after passing through the air hole 3, is broken by the groove 5, and then moves along the groove 5.

[0032] Rotate and blow inert gas under the nozzle of the present invention, the gas reaches the gas nozzle 2 through the air guide pipe 1, diffuses to the surrounding after passing through the air hole 3, and as the linear velocity increases, the bubbles are first broken...

Embodiment 2

[0034] Use the existing common rotary blowing device and the rotary blowing device of the present invention to carry out dehydrogenation of the aluminum melt under the same ventilation flow rate, the rotary blowing time is equal, and take the aluminum melt at four times after the blowing is completed. The body casting test bar was tested, and the mechanical properties of the products were compared as shown in the following table:

[0035] Table 1: Hydrogen removal by blowing with existing common rotary nozzles:

[0036]

[0037] Table two: Utilize the rotary injection device of the present invention to carry out injection dehydrogenation:

[0038]

[0039] It can be seen from Table 1 and Table 2 that the aluminum melt casting test rod obtained after the rotary blowing device of the present invention is blown and dehydrogenated is obviously better than the existing common rotary spraying in terms of tensile strength and elongation after fracture. The aluminum melt obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com