Device and method for smelting antimony

The technology of a smelting device and a smelting method, which is applied in the field of antimony smelting devices, can solve the problems of complex process and high energy consumption, and achieve the effects of high safety, large output and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

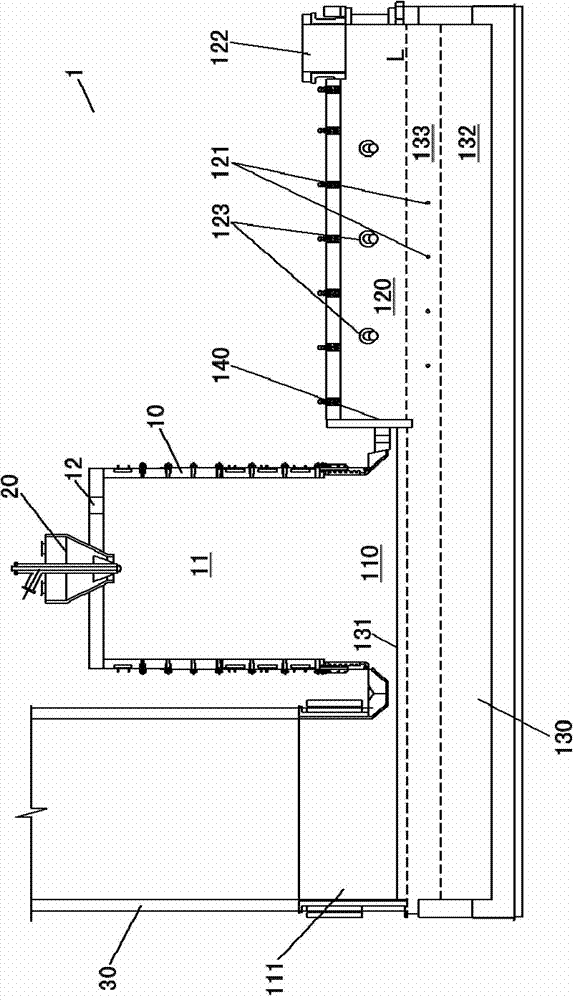

Embodiment 1

[0077] The main chemical composition (dry basis, wt%) of the powdered brittle antimony lead ore is shown in Table 1.

[0078] Table 1

[0079] Element name

Sb

Pb

As

Cu

Bi

Ag

S iO 2

CaO

Fe

S

Zn

Content (g / t)

35.41

9.45

0.31

0.3

0.0055

926

5.13

2.85

5.34

22.4

5.81

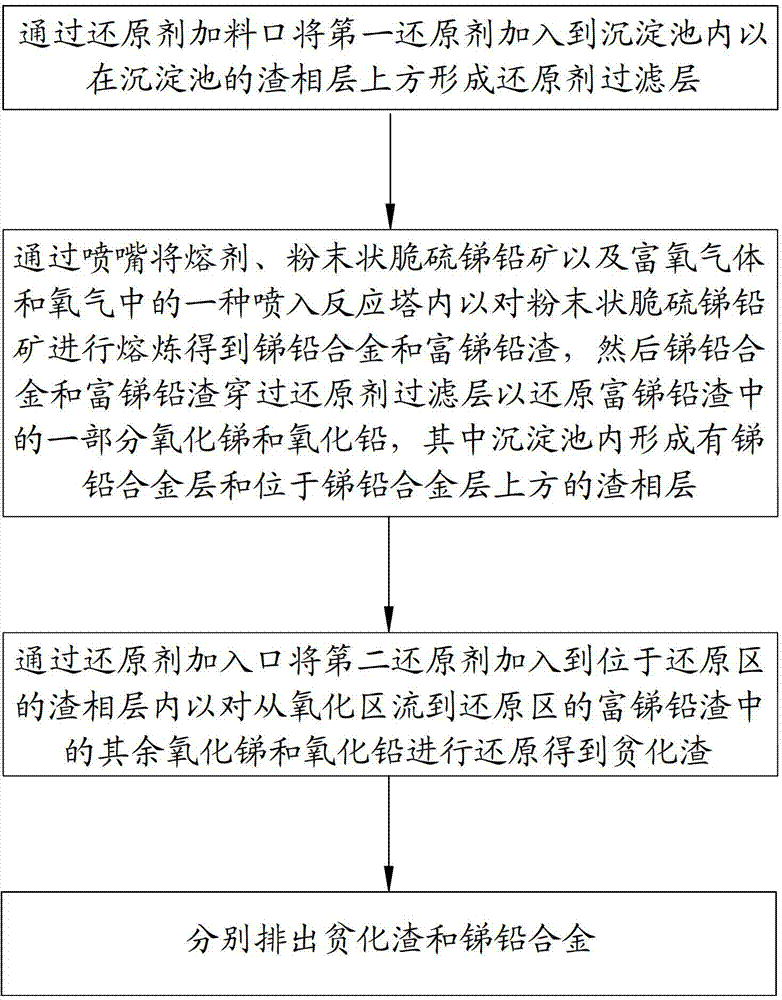

[0080] The coke is fed into the precipitation tank 130 through the reducing agent feeding port to form the reducing agent filtering layer 131. Mix limestone and powdered brittle sulfite with a particle size of no more than 100 microns in a ratio of 1:20 (weight ratio), and then use an oxygen-rich gas with an oxygen content of 40v% to mix limestone and powdered brittle sulfite Spray into the reaction tower 10, and smelt the powdered brittle antimony lead ore at 1100 degrees Celsius to obtain antimony-lead alloy and antimony-rich lead slag. Among them, the water content of limestone and powdered brittle antimony lead ore is not more than 0.3wt%.

[0081] The pulverized coal is added to the slag phase layer 1...

Embodiment 2

[0084] The powdered brittle antimonite used in this example is the same as the powdered brittle antimonite used in Example 1.

[0085] The coke is fed into the precipitation tank 130 through the reducing agent feeding port to form the reducing agent filtering layer 131. Mix pulverized coal, quartz sand and powdered brittle antimony lead ore with a particle size not greater than 80 microns (the weight ratio of quartz sand and powdered brittle antimony lead ore is 1:5), and then use the oxygen content of 99.6v% The oxygen-enriched gas will spray the mixture of powdered coal, quartz sand and powdered brittle antimony lead ore into the reaction tower 10, and smelt the powdered brittle antimony lead ore at 1500 degrees Celsius to obtain antimony lead alloy and Antimony-rich lead slag. Among them, the water content of pulverized coal, quartz sand and powdered brittle antimony lead ore is not more than 1wt%.

[0086] The pulverized coal is added to the slag phase layer 133 located in th...

Embodiment 3

[0089] The powdered brittle antimonite used in this example is the same as the powdered brittle antimonite used in Example 1.

[0090] The coke is fed into the precipitation tank 130 through the reducing agent feeding port to form the reducing agent filtering layer 131. Mix soot, pulverized coal, flux and powdered brittle antimony with a particle size of not more than 60 microns (flux includes limestone and quartz sand and the weight ratio of flux to powdered brittle antimony is 1:2), and then use Oxygen (i.e. pure oxygen) sprays the mixture of soot, pulverized coal, flux and powdered brittle antimony lead ore into the reaction tower 10, and smelts the powdered brittle antimony lead ore at 1300 degrees Celsius to obtain antimony Lead alloy and antimony-rich lead slag. Among them, the water content of pulverized coal, flux and powdered brittle antimony lead ore is not more than 0.5wt%.

[0091] The pulverized coal is added to the slag phase layer 133 located in the reduction zone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com