A device and dehydrogenation method for fluidized dehydrogenation of titanium hydride powder

A titanium hydride powder and fluidization technology, which is applied in the field of metal powder preparation, can solve the problems of difficult industrial production, long process flow, high vacuum degree, etc., and achieve the effects of short dehydrogenation time, easy control of impurity content, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

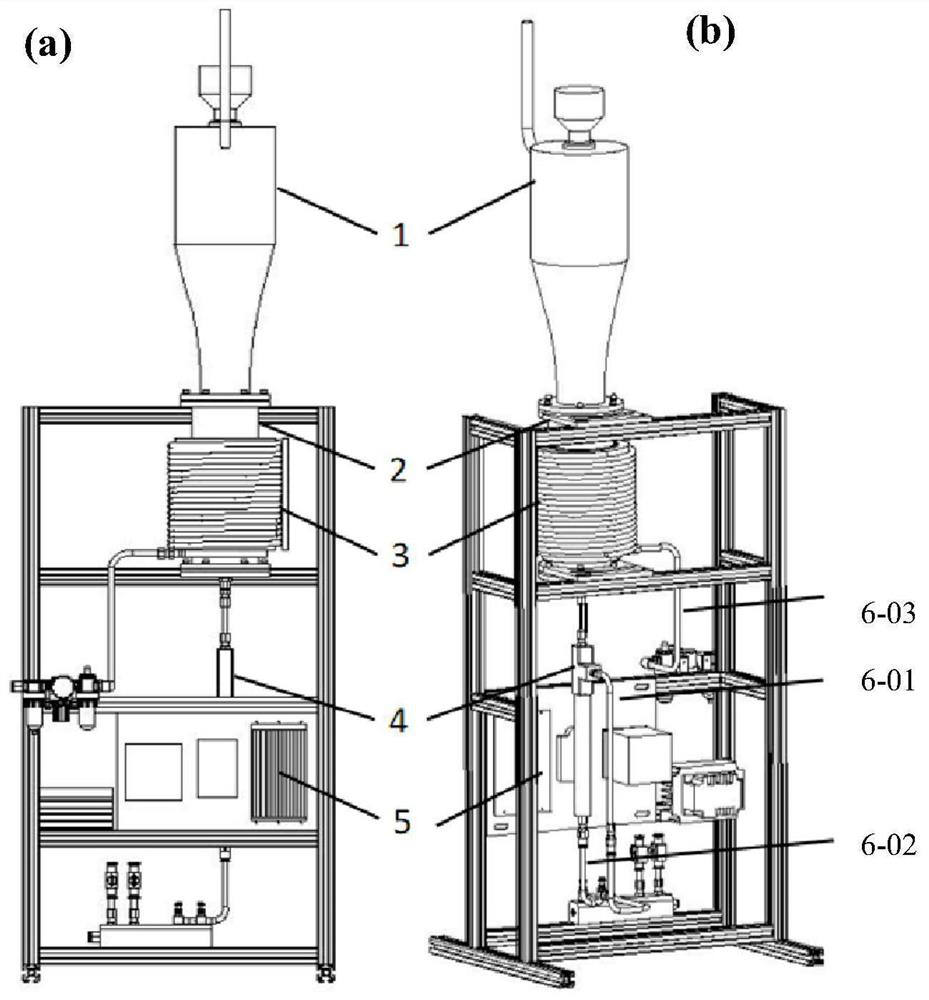

[0044] Such as figure 1 As shown, the present invention provides a device for fluidized dehydrogenation of titanium hydride powder, which includes a cyclone powder gas separation chamber 1, a fluidized reactor 2, a mica electromagnetic induction coil 3, an industrial heat gun 4 and a temperature control panel 5.

[0045]The fluidized reactor 2 is also provided with a first ventilation pipeline 6-01 and a second ventilation pipeline 6-02, and an industrial heat gun 4 is also arranged on the pipeline connected between the second ventilation pipeline 6-02 and the fluidized reactor 2 , the first ventilation pipe 6-01 is used to directly pass cold argon into the fluidized reactor 2, and the second ventilation pipe 6-02 is used to heat the incoming argon gas into the fluidized reactor 2 after being heated by the industrial heat gun 4 Inside.

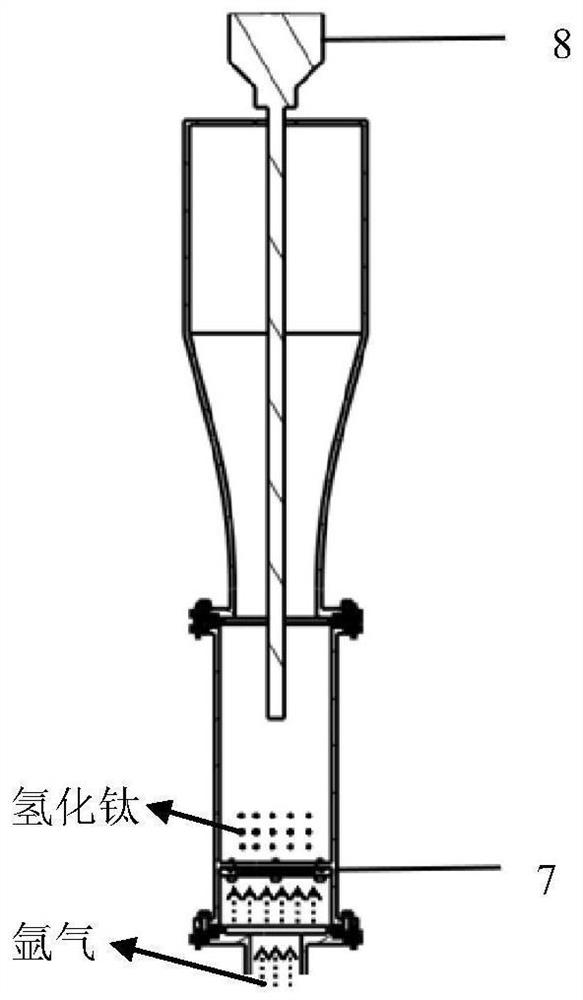

[0046] A fluidized disc 7 is arranged at the lower part of the inner cavity of the fluidized reactor 2 .

[0047] A method for dehydrogena...

Embodiment 2

[0050] A device for fluidized dehydrogenation of titanium hydride powder, same as embodiment 1.

[0051] A method for dehydrogenating titanium hydride powder provided in this embodiment, the method uses the device for fluidized dehydrogenation of titanium hydride powder described in Example 1, and the steps are as follows:

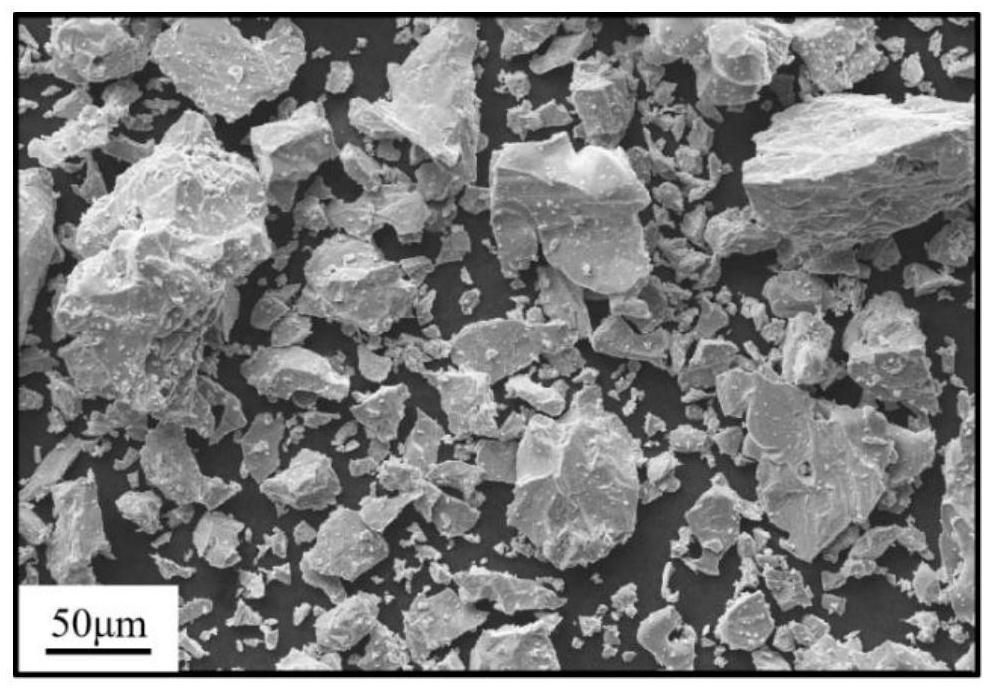

[0052] Weighing 600g average particle diameter is 75 μ m, and the titanium hydride powder that purity is 99.8% is placed on the fluidized disc 7 in the fluidized reactor 2, and bed ratio is 0.2 (the ratio of particle layer thickness and fluidized reactor height is bed ratio).

[0053] After closing the device, argon gas was introduced from bottom to top through the first ventilation pipe 6-01. After 2 minutes, the exhaust gas was detected, and it was found that the exhaust gas was all argon, indicating that the fluidized dehydrogenation of titanium hydride powder had been exhausted. air in the device.

[0054] Close the first ventilation pipe 6-01, open ...

Embodiment 3

[0057] A device for fluidized dehydrogenation of titanium hydride powder, the schematic diagram of which is shown in figure 1 with figure 2 , the device specifically includes a cyclone powder-air separation chamber 1, a fluidized reactor 2, a mica electromagnetic induction coil 3, an industrial heat gun 4 and a temperature control panel 5;

[0058] The lower end of the cyclone powder-gas separation chamber 1 is connected with a fluidized reactor 2, the outer circumference of the cylinder wall of the fluidized reactor 2 is provided with a mica electromagnetic induction coil 3, and the lower part of the inner chamber of the fluidized reactor 2 is provided with a fluidized disk 7;

[0059] The fluidized reactor 2 communicates with argon through the first ventilation pipe 6-01 arranged below it;

[0060] The fluidized reactor 2 communicates with the argon gas through the second ventilation pipeline 6-02 arranged below it, and an industrial heat gun 4 is arranged on the second ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com