Gas barrier film

A gas barrier and substrate film technology, which is applied to flexible coverings, devices for coating liquid on the surface, containers, etc., can solve the problems of decreased adhesion between the evaporated inorganic oxide layer and the gas barrier layer, and productivity. Eliminates problems such as laminate film layer peeling, and achieves excellent water vapor barrier properties, excellent production adaptability, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

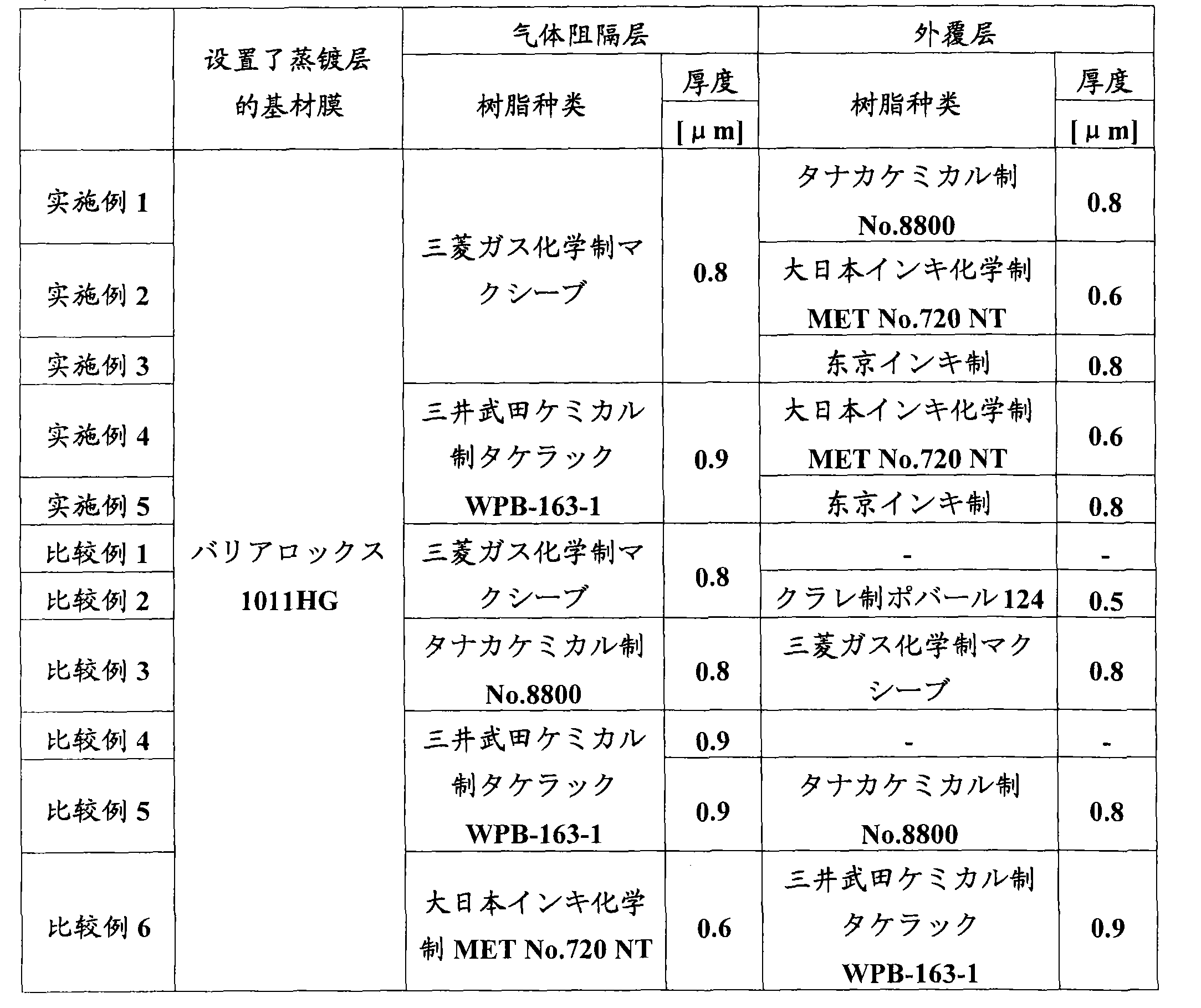

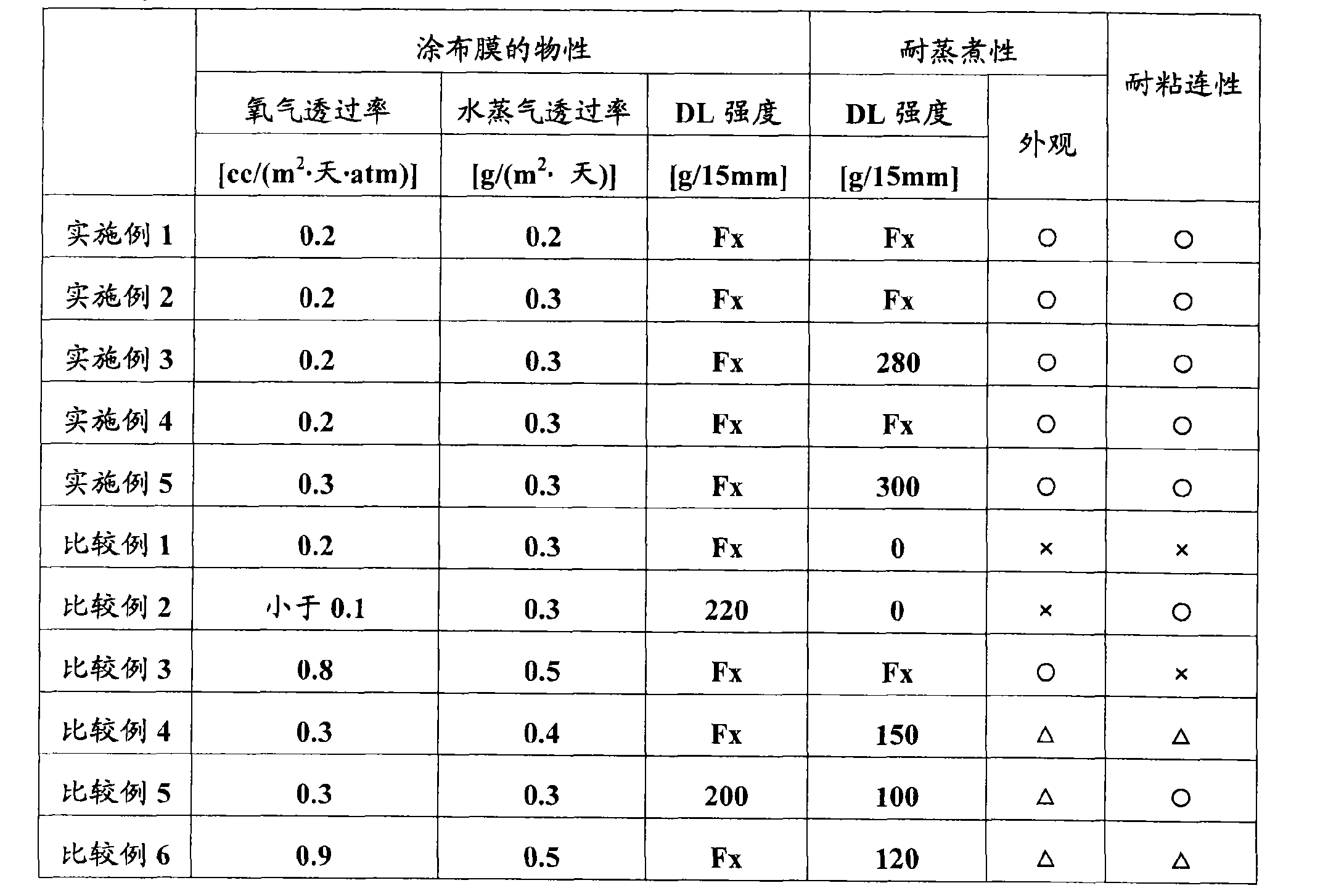

Embodiment 1

[0095] 10.0 parts, 32.1 parts of M-93 (curing agent), 32.1 parts of M-93 (curing agent) and 10.0 parts of polyepoxy resin coating agent Macshi-bu M-100 (main agent) produced by Mitsubishi Gas Chemical Co., Ltd. containing the skeleton structure shown in the above formula (1) 99.2 parts and 12.2 parts of ethyl acetate were stirred for 30 minutes to prepare a gas barrier coating liquid 1 having a solid content concentration of 20% by weight.

[0096] As a substrate film provided with a vapor-deposited layer, a biaxially stretched polyethylene terephthalate film was prepared on one side of a biaxially stretched polyethylene terephthalate film with an aluminum oxide layer by vapor deposition. ) 1011HG. The gas barrier coating liquid 1 was coated on the vapor deposition layer using a wire bar, and dried at 140° C. for 30 seconds to form a polyepoxide having a thickness of 0.8 μm and having a skeleton structure represented by the above formula (1). It is a gas barrier layer formed ...

Embodiment 2

[0103] Weigh 10.0 parts of polyester resin coating agent MET No.720NT manufactured by Dainippon Inki Chemical Industry Co., Ltd., 0.1 part of curing agent KO-55 manufactured by Dainippon Inki Chemical Industry Co., Ltd., and 20.5 parts of ethyl acetate The ester was stirred for 30 minutes to prepare a coating liquid 2 having a solid content concentration of 10% by weight. A coated film 2 and a laminated film 2 were obtained in the same manner as in Example 1, except that the coating liquid 2 prepared as above was used instead of the coating liquid 1 to provide a coating layer made of polyester resin.

Embodiment 3

[0105] For 10.0 parts of polyacrylic resin coating agent LG-VM coating agent B manufactured by Tokyo Inki Co., Ltd., 1.0 parts of curing agent LG-VM curing agent D manufactured by Tokyo Inki Co., Ltd., and 5.0 parts of ethyl acetate Stirring was carried out for 30 minutes to prepare a coating liquid 3 having a solid content concentration of 9.4% by weight. The coated film 3 and the laminated film 3 were obtained in the same manner as in Example 1, except that the coated liquid 3 prepared as described above was used instead of the coated liquid 1 and an overcoat layer made of polyacrylic resin was provided.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com