Antistatic ceramic prepared from large admixing amount red mud taken as raw material and sintered in roller kiln and preparation method thereof

A roller kiln and anti-static technology, applied in the production of ceramic materials, clay products, other household appliances, etc., can solve the problems of low utilization rate of red mud random stacking, small deformation of anti-static ceramics, limited recycling channels, etc. It is beneficial to large-scale industrial production, the anti-static performance can be adjusted, and the deformation is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

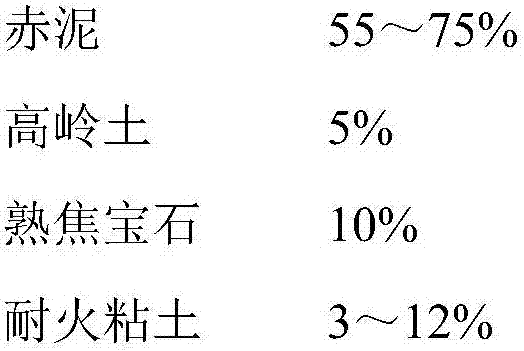

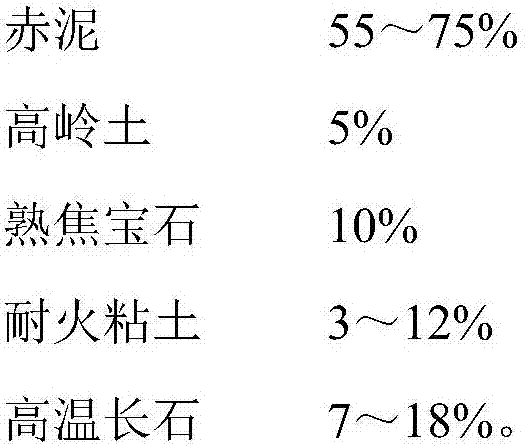

[0022] (1) Dosing according to mass percentage, prepare a mixed material containing 55% red mud, 5% kaolin, 10% burnt gemstone, 12% refractory clay and 18% high-temperature feldspar, according to the mass ratio of water and mixed material is 35 The ratio of :65 is mixed with water, and the slurry is obtained after grinding for 10 minutes on a fast grinder, and the ground slurry is dried to obtain a dry powder, and the ceramic powder is made by a pelletizing machine or by hand;

[0023] (2) Put the ceramic powder prepared by step (1) into the mold, mold it at 200MPa, dry it at 150°C for 1 hour, put it into the roller kiln and burn it at 1160°C, the firing cycle is 70 Minutes, that is, anti-static ceramics.

[0024] After testing, the water absorption rate of the antistatic ceramic obtained in this embodiment is 0.1%, and the flexural strength is 33 MPa. According to the test method stipulated in the national standard GB1410-2006, the surface resistance and volume resistance of...

Embodiment 2

[0026] (1) Dosing according to mass percentage, prepare a mixed material containing 65% red mud, 5% kaolin, 10% burnt gemstone, 7% refractory clay and 13% high-temperature feldspar, according to the mass ratio of water to mixed material is 35 The ratio of :65 is mixed with water, and the slurry is obtained after grinding for 10 minutes on a fast grinder, and the ground slurry is dried to obtain a dry powder, and the ceramic powder is made by a pelletizing machine or by hand;

[0027] (2) Put the ceramic powder prepared by step (1) into a mold and mold it at 200MPa, dry it at 150°C for 1 hour, put it into a roller kiln and burn it at 1155°C, and the firing cycle is 70 minutes , That is, anti-static ceramics.

[0028] After testing, the water absorption rate of the antistatic ceramic obtained in this embodiment is 0.4%, and the flexural strength is 29 MPa. According to the test method stipulated in the national standard GB1410-2006, the surface resistance and volume resistance ...

Embodiment 3

[0030](1) Dosing according to mass percentage, prepare a mixed material containing 75% red mud, 5% kaolin, 10% burnt gemstone, 3% refractory clay and 7% high-temperature feldspar, according to the mass ratio of water to mixed material is 35 The ratio of :65 is mixed with water, and the slurry is obtained after grinding for 10 minutes on a fast grinder, and the ground slurry is dried to obtain a dry powder, and the ceramic powder is made by a pelletizing machine or by hand;

[0031] (2) Put the ceramic powder prepared by step (1) into a mold and mold it at 200MPa, dry it at 150°C for 1 hour, put it into a roller kiln and burn it at 1150°C, and the firing cycle is 70 minutes , That is, anti-static ceramics.

[0032] After testing, the water absorption rate of the antistatic ceramic obtained in this embodiment is 0.9%, and the flexural strength is 25 MPa. According to the test method stipulated in the national standard GB1410-2006, the surface resistance and volume resistance of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com