Baking-free fireproofing brick and preparation method thereof

A technology for refractory bricks and vanadium iron slag, which is applied in the field of unfired refractory bricks and its preparation, and can solve the problems of stacking and pollution of vanadium iron slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

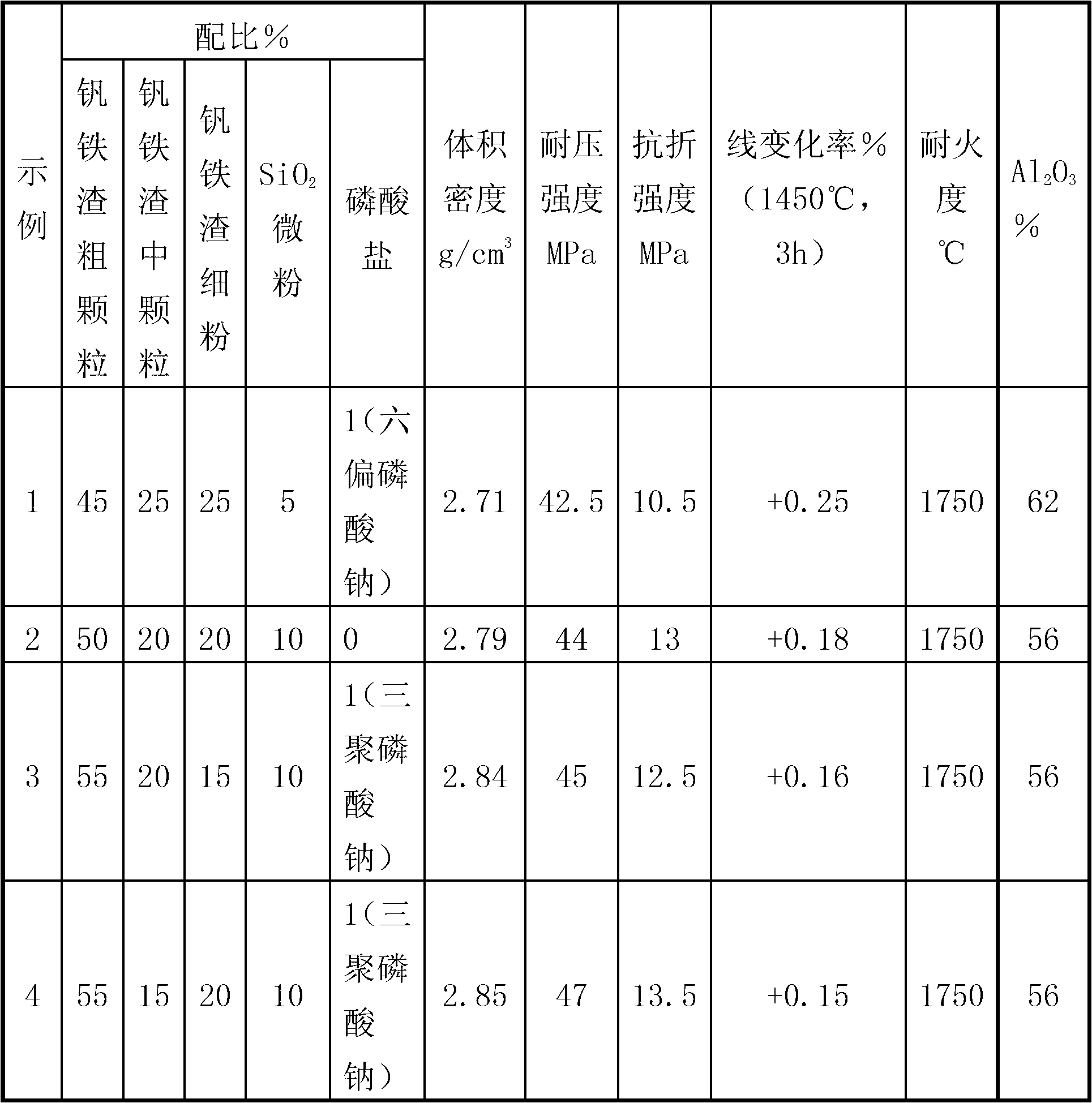

Examples

Embodiment Construction

[0013] Hereinafter, the present invention will be described in detail in combination with specific embodiments. Unless otherwise specified, the percentages mentioned in the present invention are all percentages by weight.

[0014] The main train of thought of the present invention is to utilize vanadium iron slag to match SiO 2 Micropowder is used as the binder of refractory bricks, adding phosphate to improve the mixing and dispersing performance of the material, and then through pressing molding and humidification curing, the binder in the brick adobe is hydrated as much as possible and the strength is generated, and then dried. Burning refractory bricks can achieve the purpose of sintering during use.

[0015] In terms of weight percentage, the unfired refractory brick according to the exemplary embodiment of the present invention includes 90-95% ferrovanadium slag, 5-10% SiO 2 Micropowder and additional phosphate, among which, ferrovanadium slag and SiO 2 The total mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com