Sintered flux for LPG ship welding and preparation method and application thereof

A technology of sintered flux and form, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of late start and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

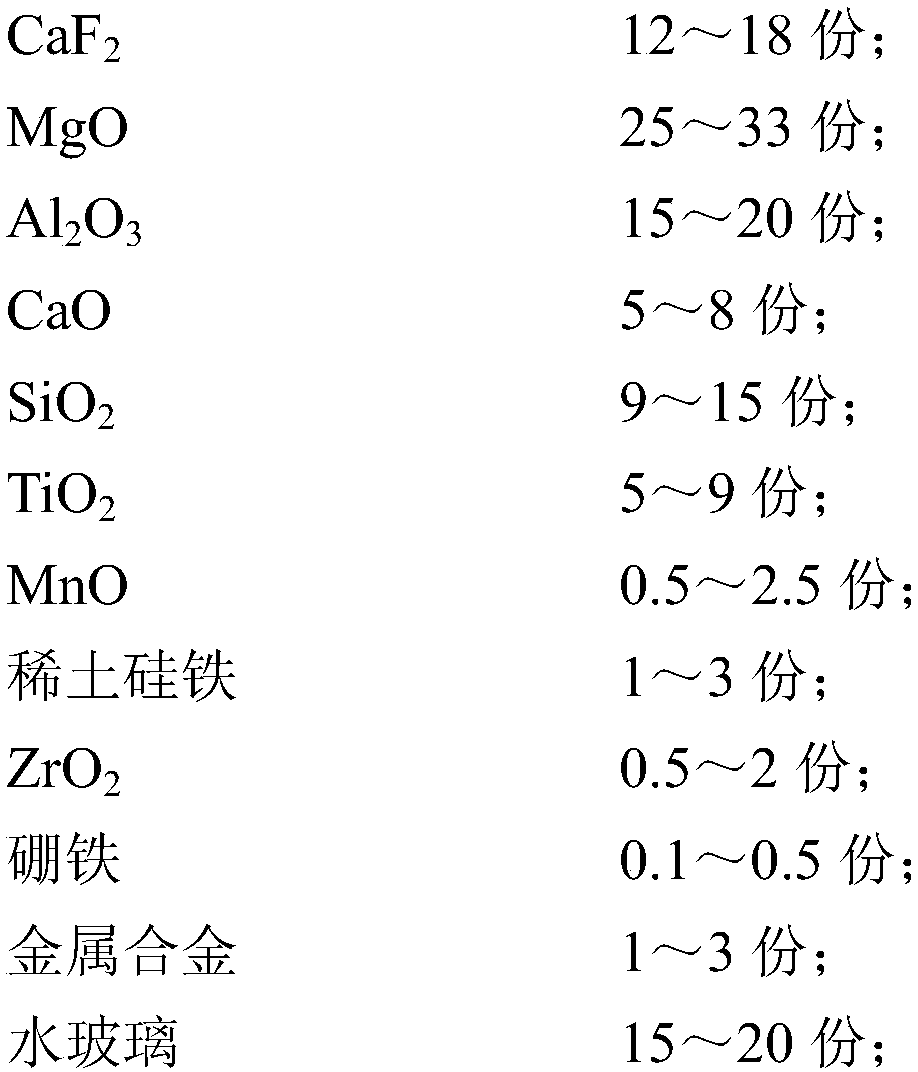

[0066] A sintered flux for LPG ship welding is a fluorine-alkaline sintered flux, and the main slag system is mainly composed of CaF 2 -MgO-Al 2 o 3 -CaO-SiO 2 System composition, comprising the following components by mass parts:

[0067]

[0068] The preparation method of described LPG ship welding sintered flux, comprises the steps:

[0069] (1) each component of the sintered flux used for LPG ship welding is carried out batching except potassium-sodium water glass and dry-mixed to obtain a mixture;

[0070] (2) wet mixing the mixture prepared by step (1) with potassium-sodium water glass to obtain a wet mixture;

[0071] (3) The wet mixture prepared in step (2) is granulated in a granulation tray, dried at 350°C, and sintered at a high temperature of 700°C to obtain sintered flux for LPG ship welding, wherein the particle size of the sintered flux for LPG ship welding is 12 to 40 mesh.

Embodiment 2

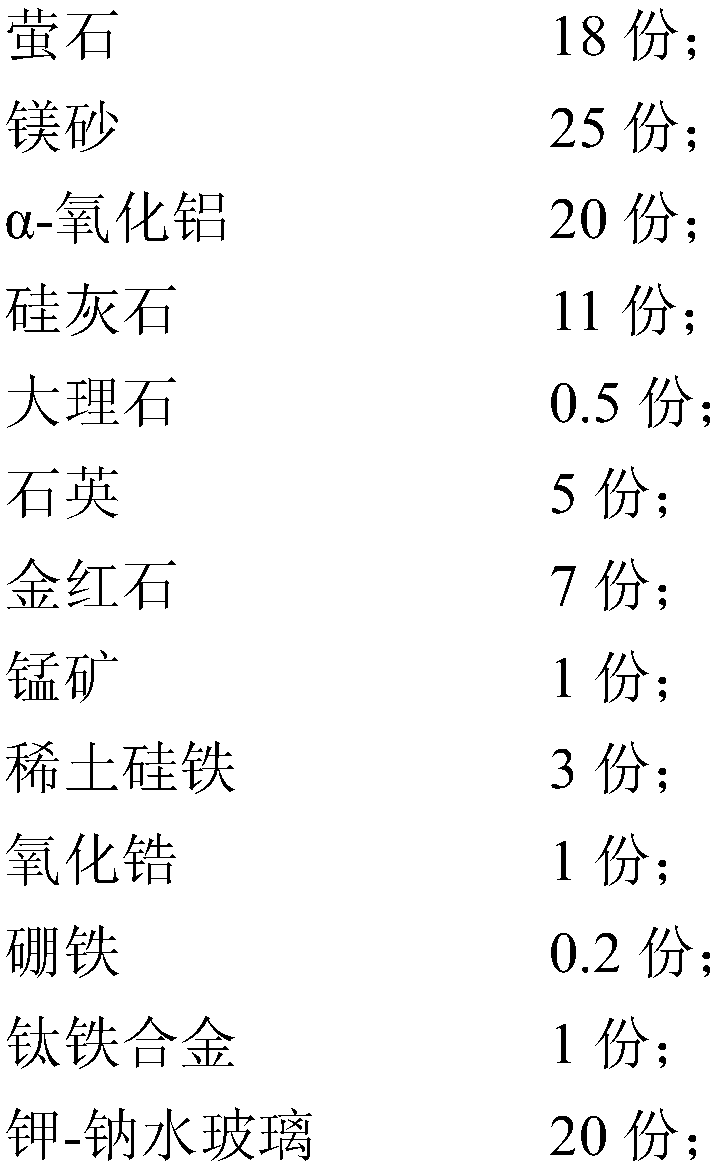

[0073] A sintered flux for LPG ship welding is a fluorine-alkaline sintered flux, and the main slag system is mainly composed of CaF 2 -MgO-Al 2 o 3 -CaO-SiO 2 System composition, comprising the following components by mass parts:

[0074]

[0075] The preparation method of described LPG ship welding sintered flux, comprises the steps:

[0076] (1) each component of the sintered flux used for LPG ship welding is carried out batching except potassium-sodium water glass and dry-mixed to obtain a mixture;

[0077] (2) wet mixing the mixture prepared by step (1) with potassium-sodium water glass to obtain a wet mixture;

[0078] (3) Granulate the wet mixture obtained in step (2) in a granulation tray, dry at 300°C, and sinter at a high temperature of 660°C to obtain sintered flux for LPG ship welding, wherein the particle size of the sintered flux for LPG ship welding is 12 to 40 mesh.

Embodiment 3

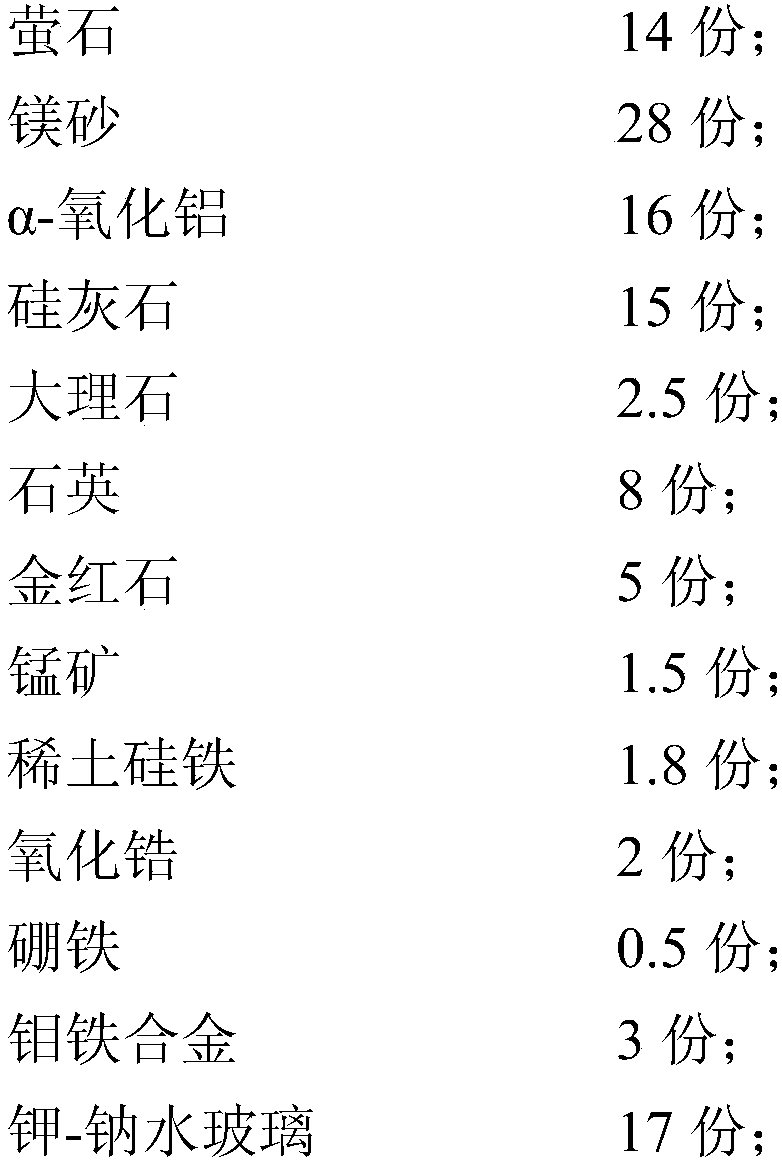

[0080] A sintered flux for LPG ship welding is a fluorine-alkaline sintered flux, and the main slag system is mainly composed of CaF 2 -MgO-Al 2 o 3 -CaO-SiO 2 System composition, comprising the following components by mass parts:

[0081]

[0082]

[0083] The preparation method of described LPG ship welding sintered flux, comprises the steps:

[0084] (1) each component of the sintered flux used for LPG ship welding is carried out batching except potassium-sodium water glass and dry-mixed to obtain a mixture;

[0085] (2) wet mixing the mixture prepared by step (1) with potassium-sodium water glass to obtain a wet mixture;

[0086] (3) The wet mixture obtained in step (2) is granulated in a granulation tray, dried at 400°C, and sintered at a high temperature of 750°C to obtain sintered flux for LPG ship welding, wherein the particle size of the sintered flux for LPG ship welding is 12 to 40 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com