Environment-friendly waste cutting fluid circulation treatment method and purification device

A technology of waste cutting fluid and recycling treatment, applied in filtration treatment, multi-stage water treatment, chemical instruments and methods, etc., can solve the problems of increasing the use of waste cutting fluid, reducing the lubricity of cutting fluid, and difficult to control oil quality. , to reduce the economic burden, improve the sterilization rate, and achieve good environmental protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiments.

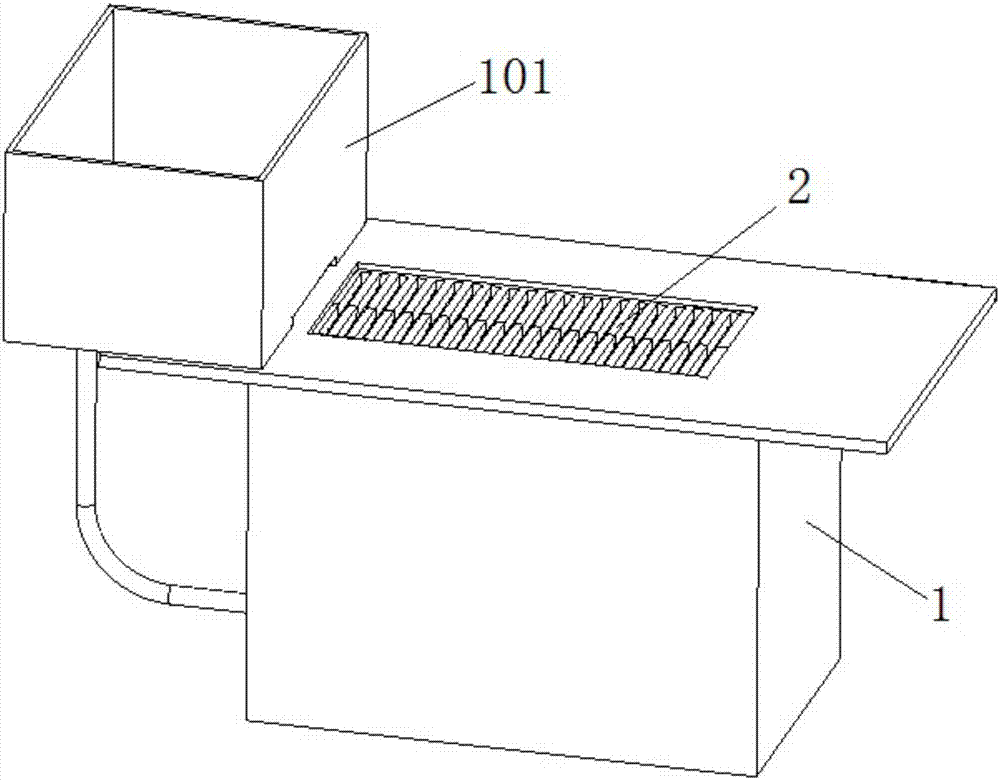

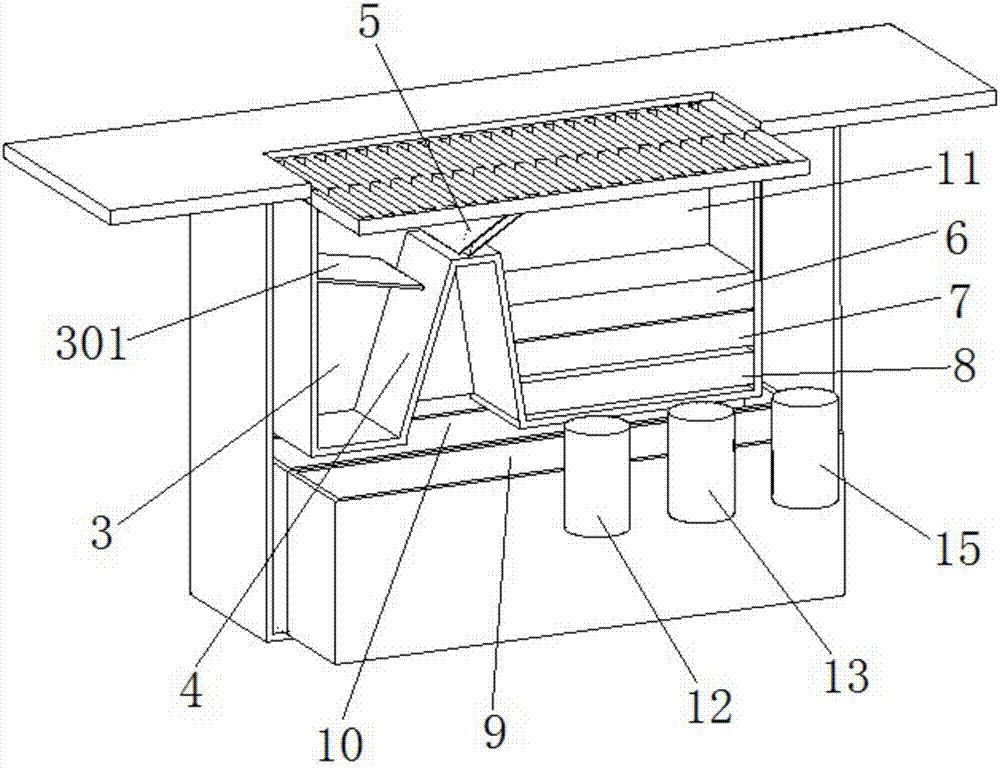

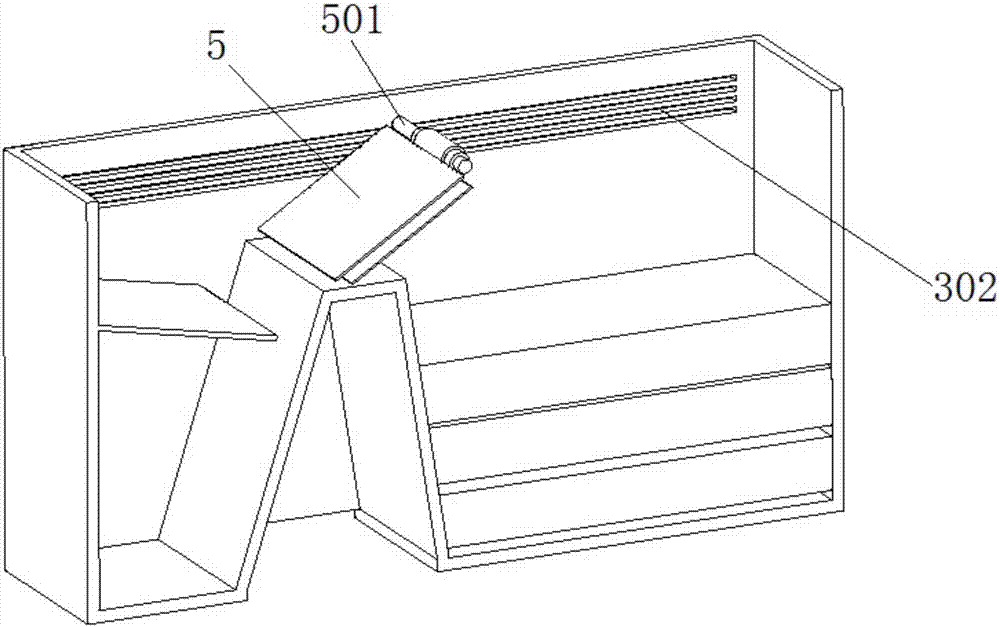

[0033] Such as Figure 1 to Figure 5 as shown,

[0034] An environment-friendly recycling and purification equipment for waste cutting fluid, comprising a body 1, a cutting fluid circulation tank 101 and a liquid inlet 2 arranged on the top of the body 1, an oil-water separation tank, a waste cutting fluid working tank 10 and a cutting fluid The temporary storage tank 9, the cutting fluid circulation tank 101, the oil-water separation tank, the waste cutting fluid working tank 10 and the cutting fluid temporary storage tank 9 are connected in sequence, the oil-water separation tank is located below the liquid inlet 2, and the waste cutting fluid in the cutting fluid circulation tank 101 The liquid first enters the oil-water separation tank, and is then transported by pumping equipment (such as a pump) to the waste cutting fluid working tank 10 and the cutting fluid tempora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com