Sintered flux for 9Ni steel welding and preparation method thereof

A technology of sintering flux and form, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of immature products, etc., and achieve the effect of uniform flux particle size, good processability and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

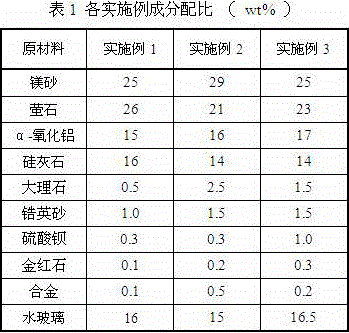

[0033] Design component content according to the present invention, provide three specific examples, prepare experimental flux according to the preparation process described in the present invention, the specific composition ratio of three examples is shown in Table 1, it should be noted that the present invention does not limited to these examples.

[0034]

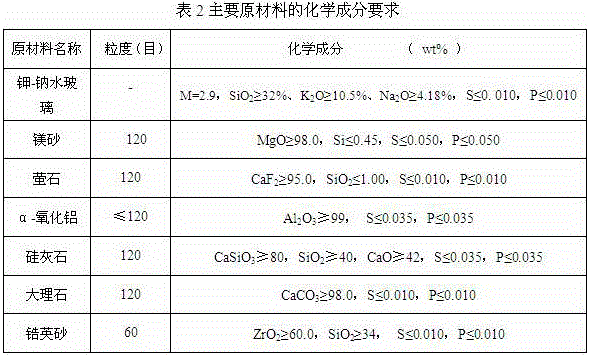

[0035] The chemical composition requirement of the main raw material of flux of the present invention is as follows table 2:

[0036]

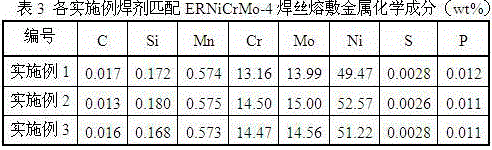

[0037] The fluxes made in the above three embodiments were tested. Before the welding test, the flux was baked at 320~350℃ for 1 hour, and then matched with ERNiCrMo-4 submerged arc welding wire respectively. Taking Φ2.4mm welding wire as an example, the welding process parameters are: welding power supply DC reverse connection, welding current 320~350A, The welding voltage is 28~30V, and the interpass temperature is 100~150℃. The test results are shown in Table 3 and Table 4.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com