Nitric acid recycling system

A technology of nitric acid and dilute nitric acid, applied in the directions of nitric acid, nitrogen oxides/oxyacids, etc., can solve the problems of substandard waste liquid, waste of acid resources, pollution of the environment, etc., and achieve full recycling, saving production costs and investment costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

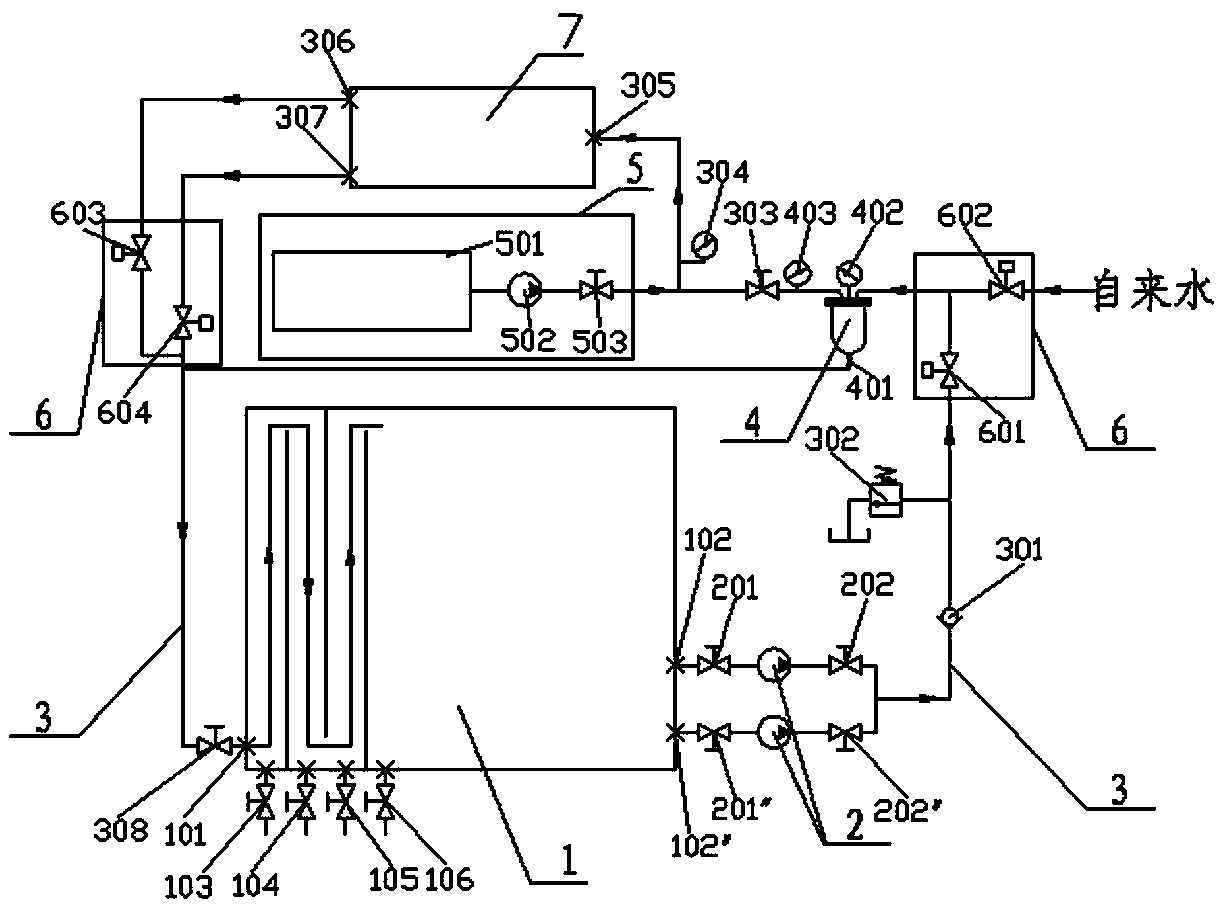

[0027] Such as figure 1 As shown, it consists of dilute nitric acid recovery deposition storage tank 1, stainless steel magnetic pump 2, stainless steel pipeline for conveying and recovery 3, stainless steel filter device 4, concentrated nitric acid automatic liquid replenishment device 5, and electrical automatic control device 6;

[0028] The dilute nitric acid recovery deposition storage box 1 is welded by stainless steel plates, and is provided with an acid return port 101, an acid outlet 102, and an acid outlet 102"; the dilute nitric acid recovery deposition storage tank 1 is provided with four return partitions area, and at the bottom of each partition area, there are stainless steel ball valve a 103, stainless steel ball valve b 104, stainless steel ball valve c 105, stainless steel ball valve d 106;

[0029] Described stainless steel magnetic force pump 2 is that two stainless steel magnetic force pumps 2 are respectively connected with the acid outlet 102 and the aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com