UV drying curing system added on rotogravure printing machine

A gravure printing machine and drying technology, which is applied to the general parts of printing machinery, printing machines, printing, etc., can solve the problem that the rotogravure printing machine cannot print leather oil, freezing point snowflakes, limit the adaptability of equipment production, and cannot complete special processes, etc. problems, to achieve the effect of expanding production adaptability, saving labor costs, and expanding the scope of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

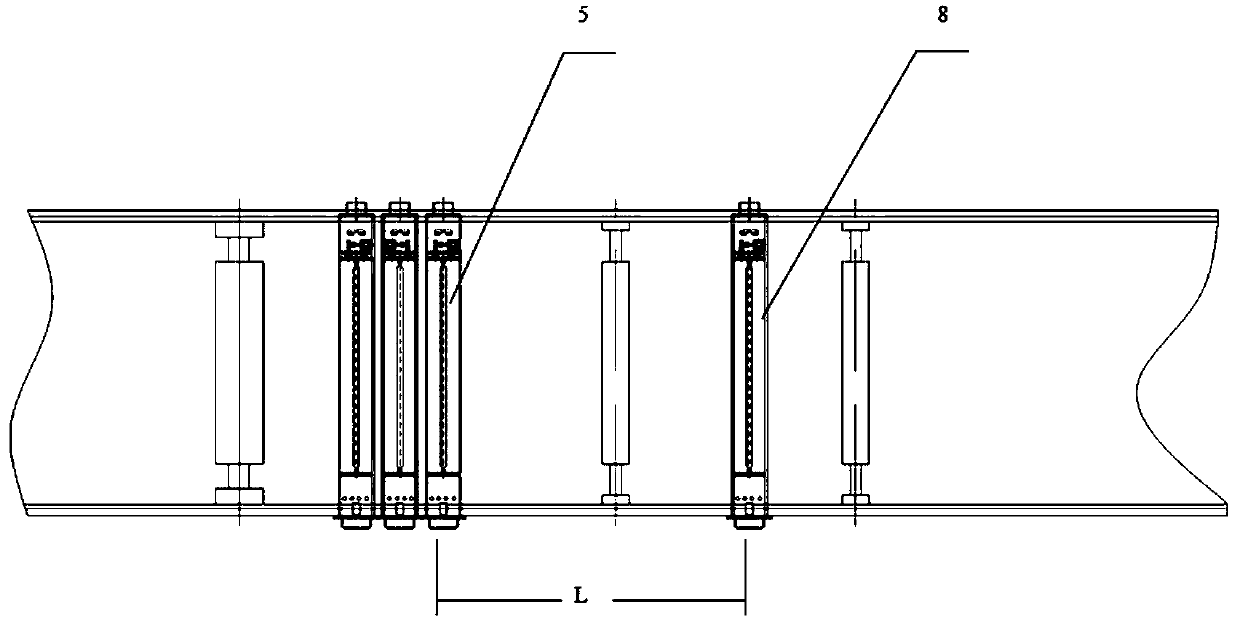

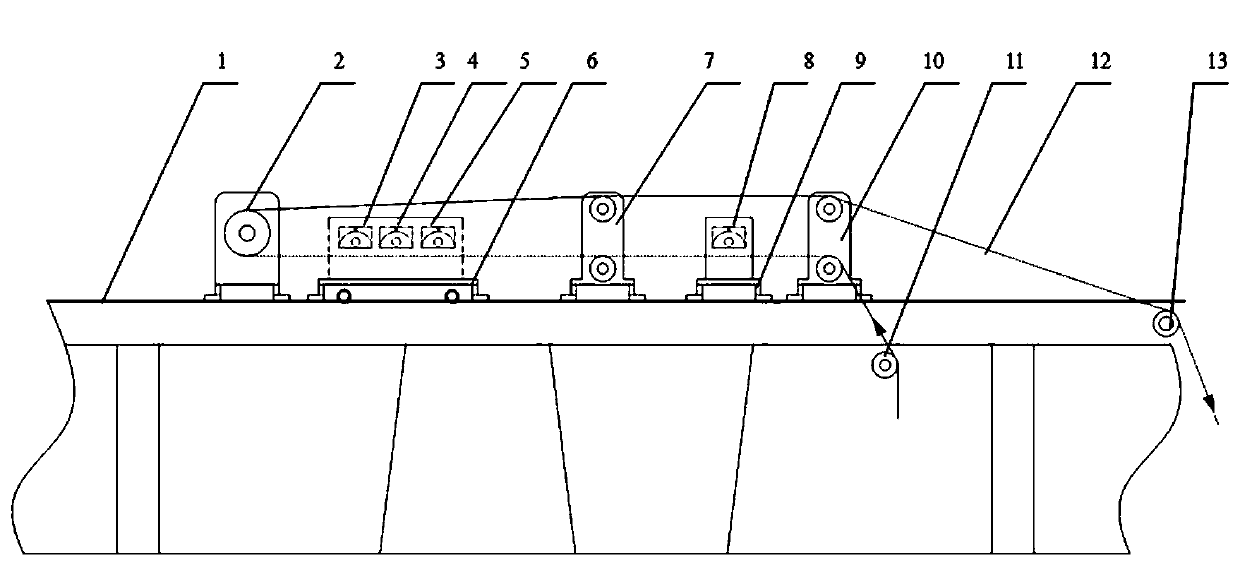

[0019] See figure 1 and figure 2 .

[0020] In this embodiment, a water-cooled shutter-type ultraviolet cold light source drying and curing system is installed on the SAY820C9 type electronic shaft-driven paper gravure printing machine.

[0021] Four sets of ultraviolet cold light sources 3, 4, 5 and 8 are placed on the top of the longitudinal beam 1 of the SAY820C9 electronic shaft transmission paper gravure printing machine. The light source 8 is mounted on a fixed bracket 9 .

[0022] Paper guide rollers 7 and 10 are arranged on the front and rear sides of the fixed support 9 , and the paper cooling roller 2 is arranged behind the movable support 6 .

[0023] The distance between the movable support 6 and the fixed support 9 is 1 to 3 meters, that is, figure 2 The variable range of L in , this range refers to the distance between the ultraviolet cold light sources 5 and 8.

[0024] The paper guide rollers 7 and 10 include two upper and lower rollers, and the paper co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com