Super energy-saving and safe intelligent electric heater

An electric heater and super energy-saving technology, applied in electric heating systems, space heating and ventilation details, heating methods, etc., can solve the problems of reducing the service life of the controller, arc oxidation at the circuit connection, and high power consumption, reaching The effect of improving heat dissipation efficiency, avoiding safety accidents and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

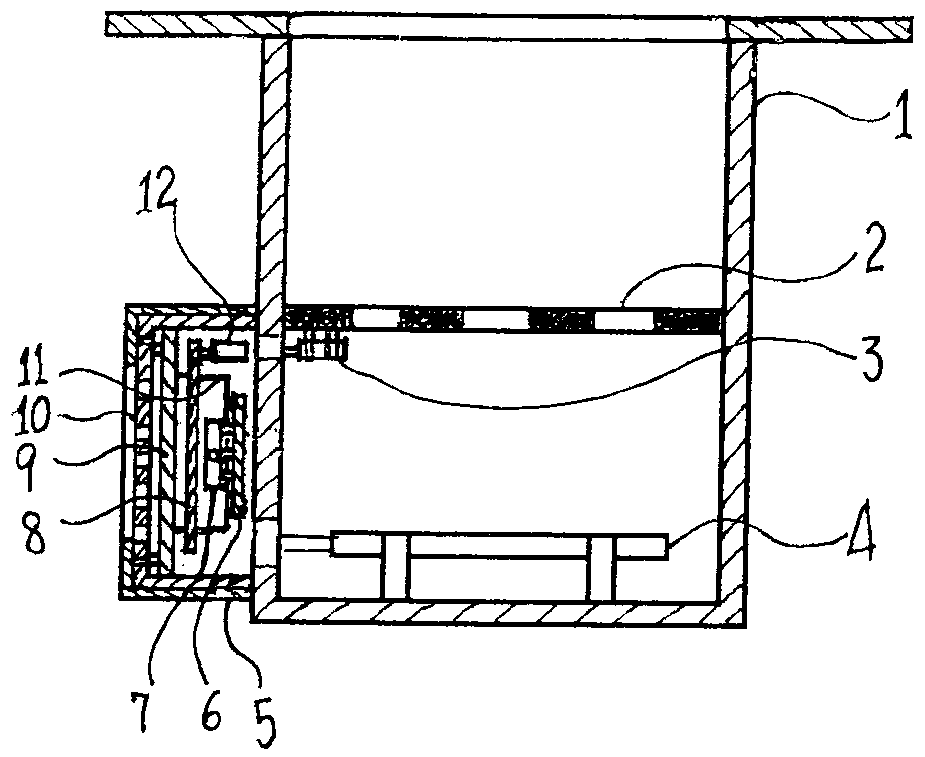

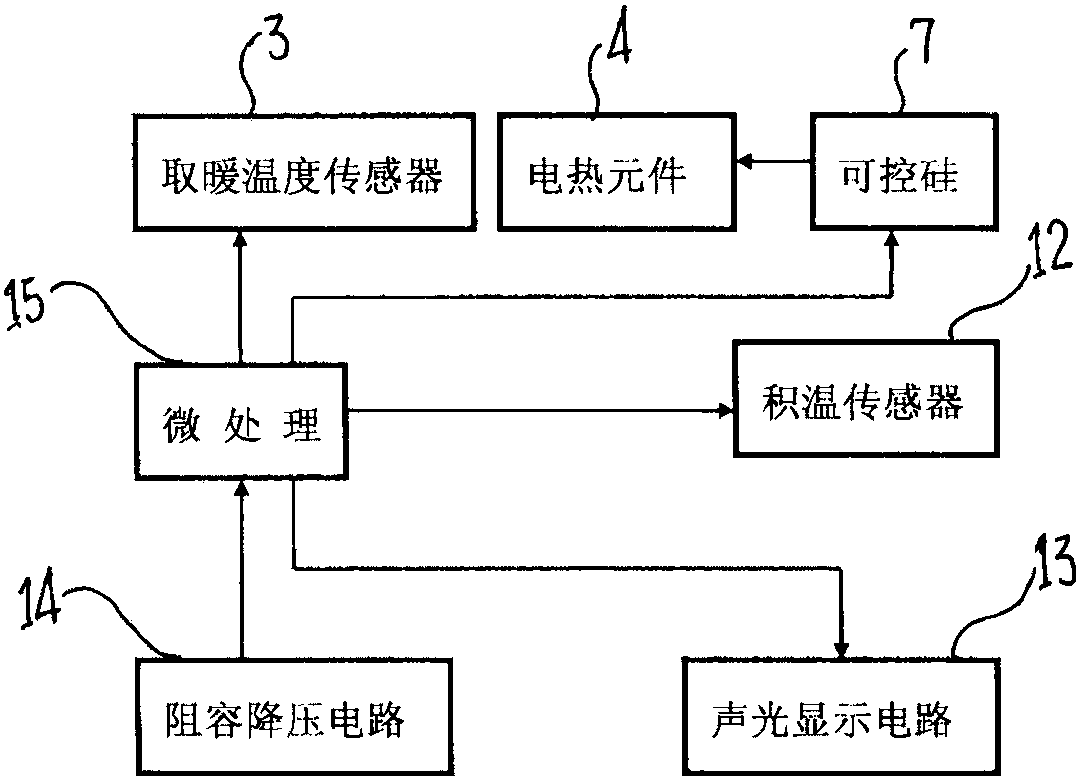

[0035] Such as figure 1 , 2As shown, the ultra-energy-saving and safe intelligent electric heater of the present invention includes a foot rest mechanism 2, an electric heating element 4, and a temperature control device 5 installed in a box body 1. A heating temperature sensor 3 is installed on the foot rest mechanism 2, and a heating temperature sensor 3 is installed on the temperature control device. 5, the accumulated temperature sensor 12 is installed, and the heating temperature sensor 3 and the accumulated temperature sensor 12 are respectively connected with the temperature control device 5.

[0036] The temperature control device 5 has a thyristor 7, and the thyristor 7 is installed on a special thyristor mounting board 6 (a circuit board for installing the thyristor or the thyristor and its related components), and the thyristor mounting board 6 and the circuit board 8 (the circuit board on which electronic components such as microprocessors are installed) are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com