Rotational conveying device and conveying line using same

A handling device and rotary shaft technology, applied in the field of conveying lines, can solve the problems of high investment cost, inability to adapt to the flexible industrial production environment, increased control difficulty, etc., to achieve high operational flexibility, wide application range, production adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

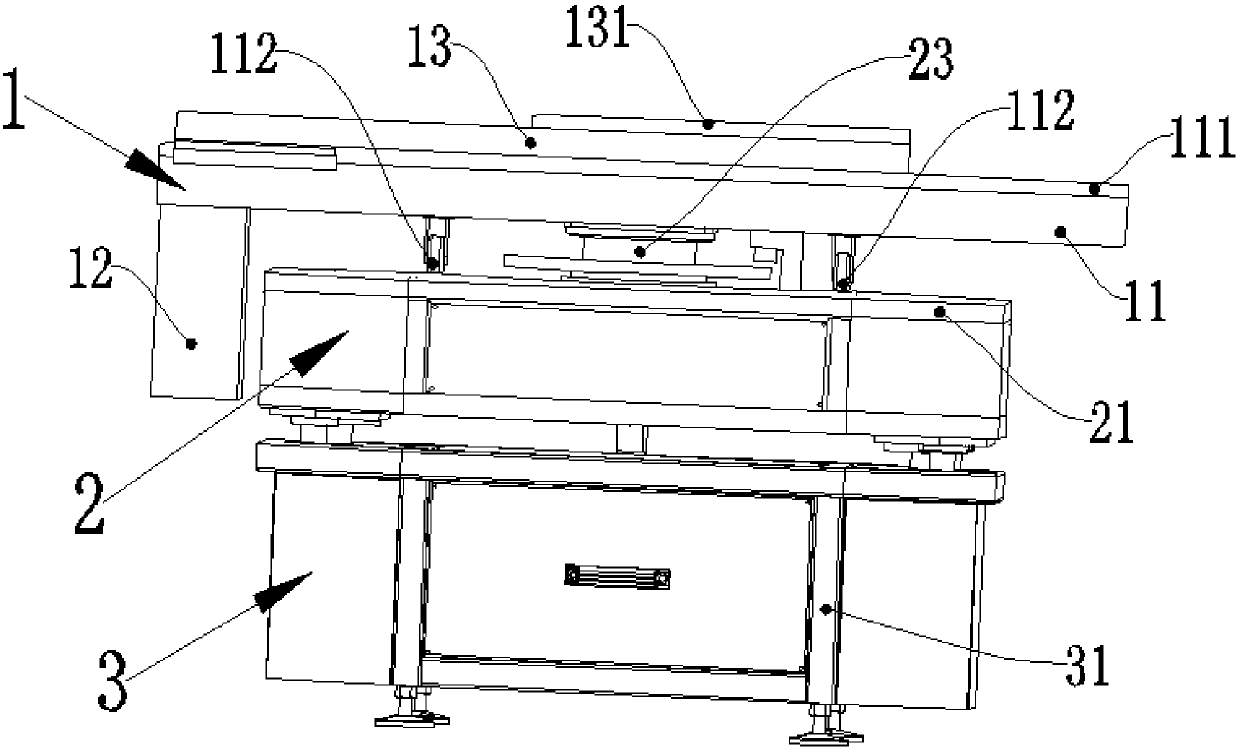

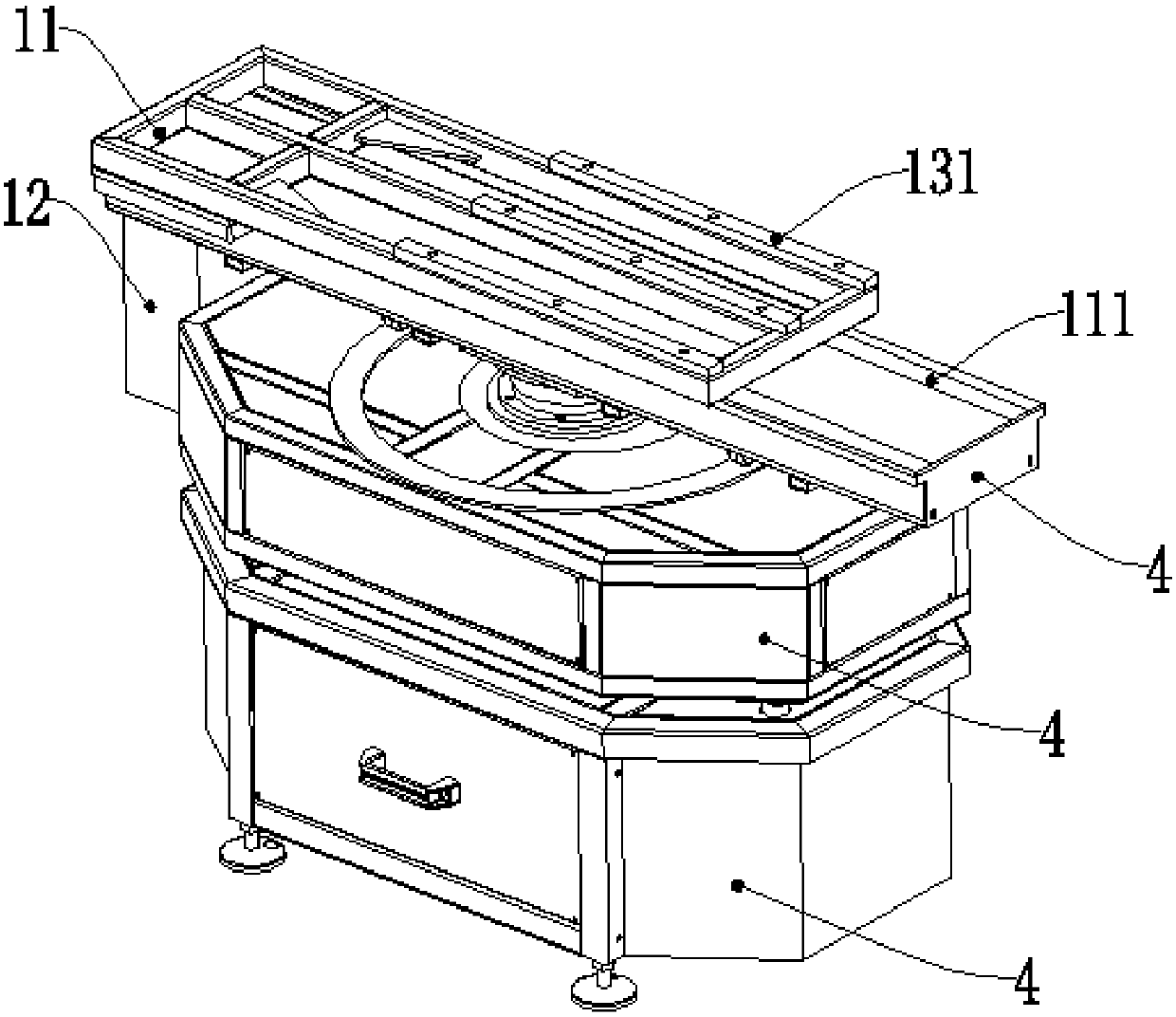

[0038] The rotary transfer device of this embodiment, such as figure 1 As shown, it includes a sliding module 1, a rotary module 2 and a lifting module 3, and the rotary module 2 is arranged between the sliding module 1 and the lifting module 3;

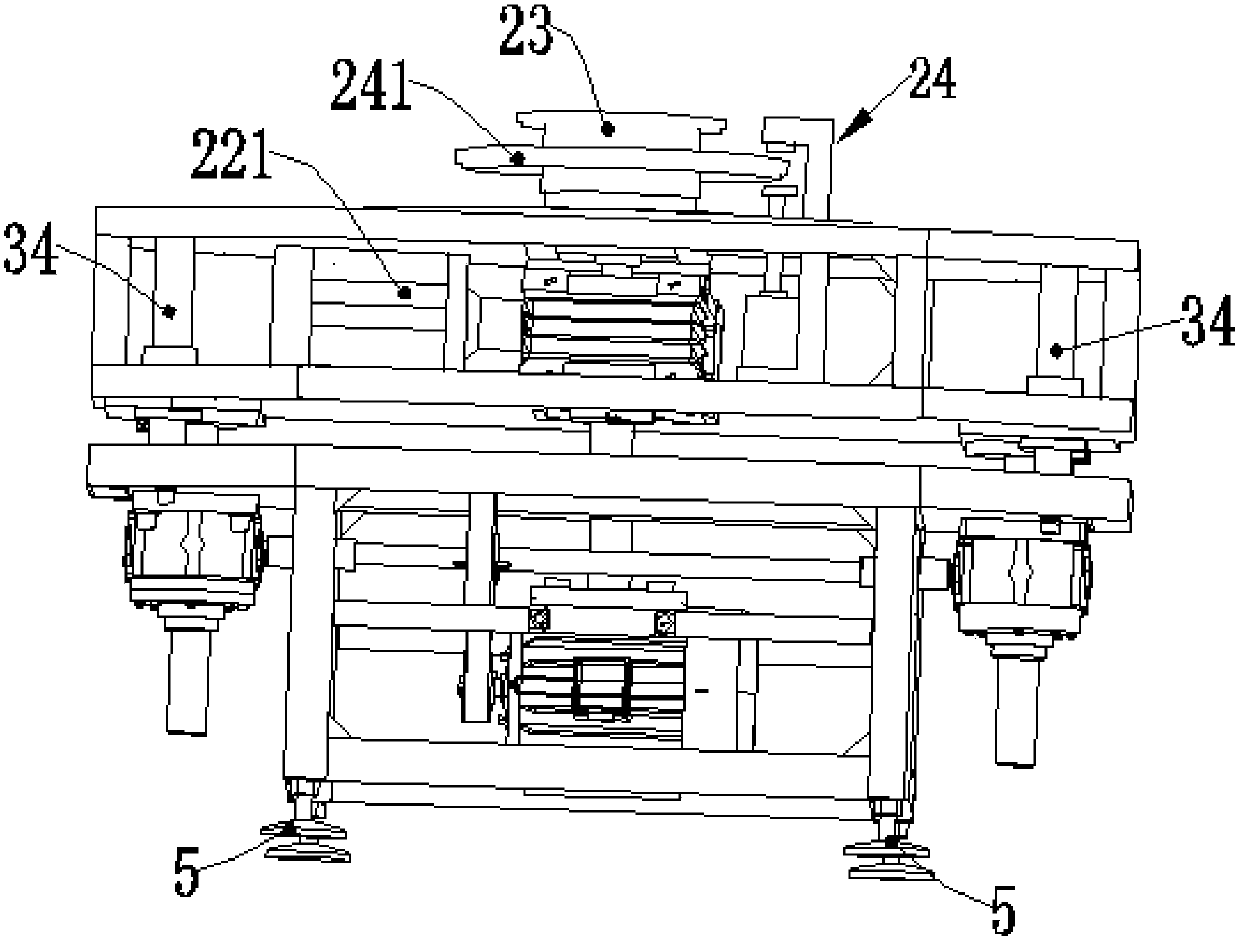

[0039] The lifting module 3 includes a lifting shaft 33, such as Figure 7 As shown, the rotary module 2 is connected to the lifting module 3 through the lifting shaft 33, and the lifting module 3 drives the rotary module 2 to lift;

[0040] The sliding module 1, the rotary module 2 and the lifting module 3 are detachable combined structures;

[0041] The rotary module 2 includes a rotary base 21, a rotary shaft 23 and a locking mechanism 24, such as image 3 , Figure 4 As shown, the sliding module 1 is connected to the rotary module 2 through the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com