Manufacturing method of high-tempered antibacterial glass cup

A manufacturing method and technology for glass cups, applied in the field of glassware, can solve the problems of low tempering strength, low light transmittance, poor antibacterial properties, etc., and achieve the effects of low cost, uniform ion concentration and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

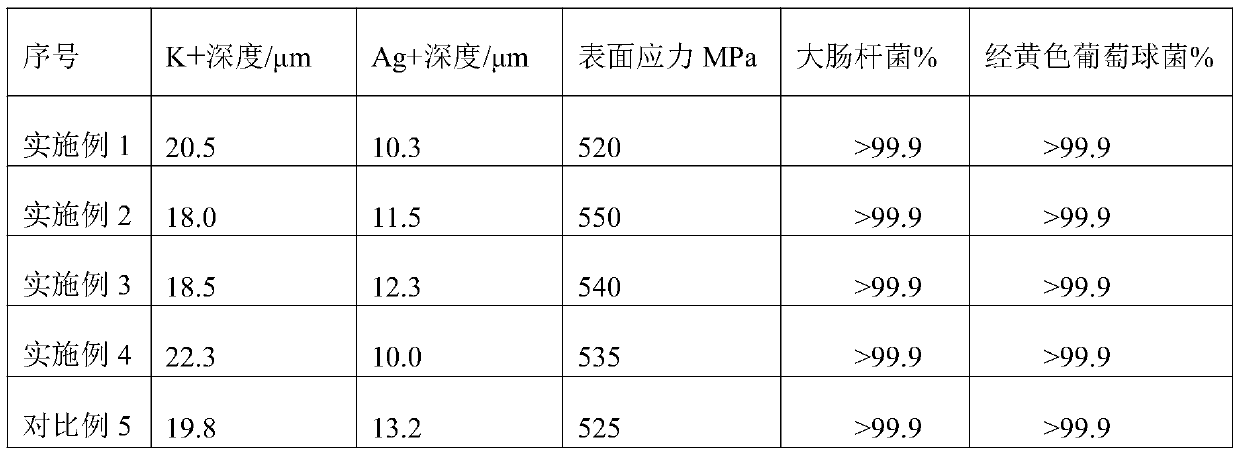

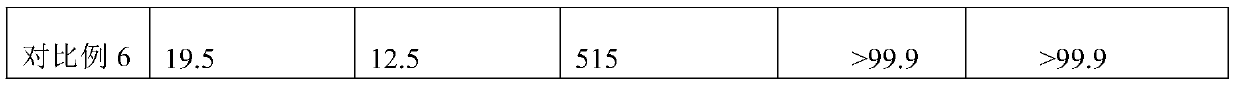

Examples

Embodiment 1

[0036] The present embodiment provides a method for manufacturing a highly tempered antibacterial glass, which specifically includes the following steps:

[0037] (1) Cleaning: ultrasonically clean the semi-finished high silicon boron glass cup;

[0038] (2) Spraying tempering agent: will contain KNO 3 (Potassium nitrate) 1kg / L aqueous solution (70℃) atomized and sprayed on the inner and outer surfaces of the glass, and KNO after drying 3 The adhesion amount is 200g / m 2 ;

[0039] (3) Annealing and tempering: heating the dried glass to 500°C at a rate of 5°C / min, annealing for 8 hours, and air-cooling to room temperature;

[0040] (4) Spraying antibacterial agent: will contain AgNO 3 (Silver nitrate) 100g / L aqueous solution was atomized and sprayed on the surface of the glass after annealing and cooling, and AgNO after drying 3 The adhesion amount is 50g / m 2 ;

[0041] (5) Antibacterial treatment: heat the glass cup containing the antibacterial agent after drying to 380...

Embodiment 2

[0044] The present embodiment provides a method for manufacturing a highly tempered antibacterial glass, which specifically includes the following steps:

[0045] (1) Cleaning: ultrasonically clean the semi-finished high silicon boron glass cup;

[0046] (2) Spraying tempering agent: will contain KNO 3 (Potassium nitrate) 0.4kg / L aqueous solution (50°C) was atomized and sprayed on the inner and outer surfaces of the glass, and KNO was dried after drying. 3 The adhesion amount is 100g / m 2 ;

[0047] (3) Annealing and tempering: heat the dried glass to 600°C at a rate of 10°C / min, keep the temperature for 2 hours, complete annealing and tempering, and air-cool to room temperature;

[0048] (4) Spraying antibacterial agent: will contain AgNO 3 (Silver nitrate) 50g / L aqueous solution is atomized and sprayed on the surface of the glass after annealing and cooling, and AgNO after drying 3 The adhesion amount is 10g / m 2 ;

[0049] (5) Antibacterial treatment: heat the glass cu...

Embodiment 3

[0052] The present embodiment provides a method for manufacturing a highly tempered antibacterial glass, which specifically includes the following steps:

[0053] (1) Cleaning: ultrasonically clean the semi-finished high silicon boron glass cup;

[0054] (2) Spraying tempering agent: will contain KNO 3 (Potassium nitrate) 2kg / L aqueous solution (65°C) atomized and sprayed on the inner and outer surfaces of the glass, and KNO after drying 3 The adhesion amount is 150g / m 2 ;

[0055] (3) Annealing and tempering: heating the dried glass to 540°C at a rate of 8°C / min, annealing for 5h, and air-cooling to room temperature;

[0056] (4) Spraying antibacterial agent: will contain AgNO 3 (Silver nitrate) 75g / L aqueous solution was atomized and sprayed on the surface of the glass after annealing and cooling, and AgNO after drying 3 The adhesion amount is 35g / m 2 ;

[0057] (5) Antibacterial treatment: heat the glass cup containing the antibacterial agent after drying to 400 °C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com