Efficient and environment-friendly rubber-powder-modified asphalt waterproof coiled material and preparing method

A technology of modified asphalt and waterproof membrane, which is applied in the direction of chemical instruments and methods, coatings, building components, etc. It can solve the problems of complex process, long production cycle, and large investment in equipment, so as to achieve simple process and reduce cost input , The effect of low equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

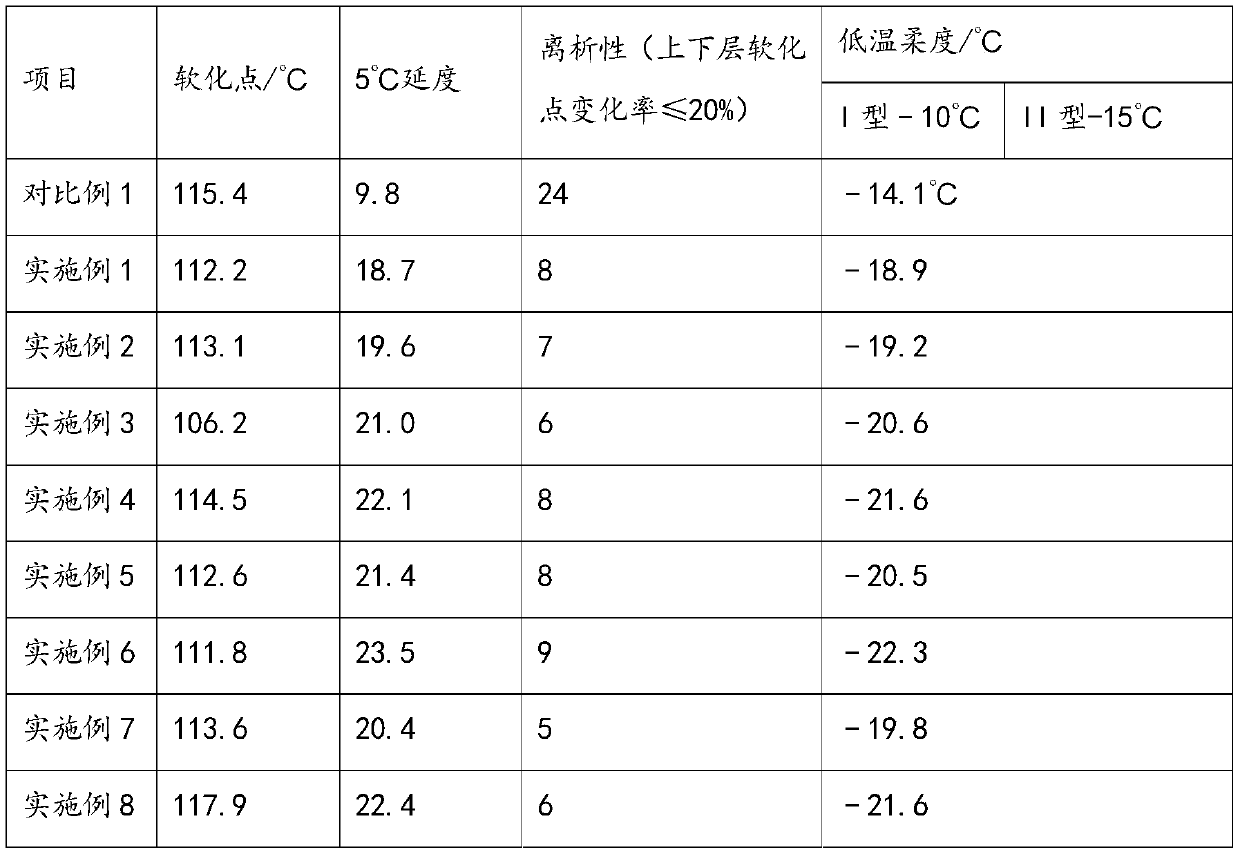

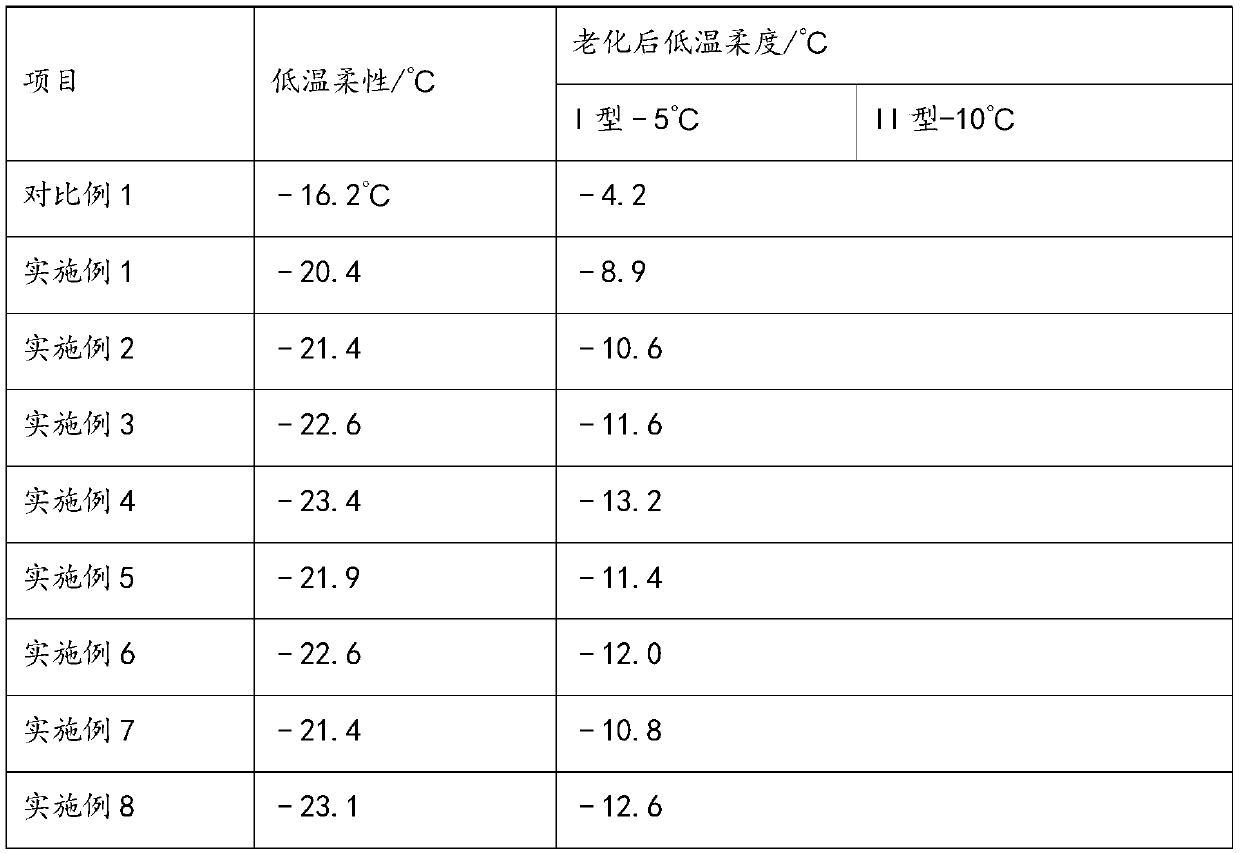

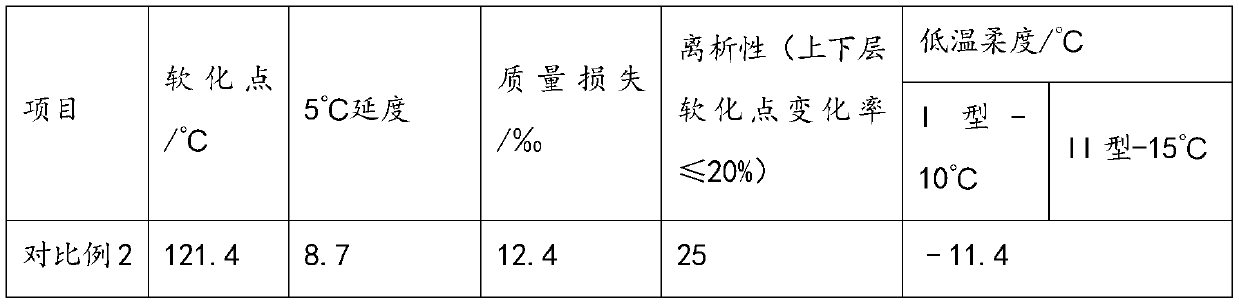

Examples

Embodiment 1

[0033] Put 48 parts of base asphalt and 8 parts of base oil into the development tank and mix them, then raise the temperature to 160°C, add 28 parts of waste rubber powder and 0.2 parts of RV rubber regeneration agent while stirring and raising the temperature, and raise the temperature to 175°C-180°C, Keep the rotation speed at 50r / min and stir for 1h. Use a colloid mill to grind one pass, then add 16 parts of talcum powder, and stir for 0.5 hours to obtain the modified asphalt material. The finished product is obtained by oiling, film coating, cooling and winding.

Embodiment 2

[0035] Put 48 parts of base asphalt and 8 parts of base oil into the development tank and mix them, then raise the temperature to 160°C, add 28 parts of waste rubber powder and 0.08RV rubber regeneration agent while stirring and raising the temperature, raise the temperature to 175°C-180°C, keep Rotate at 200r / min, stir for 1.5h. Use a colloid mill to grind one pass, then add 16 parts of talcum powder, and stir for 0.5 hours to obtain the modified asphalt material. The finished product is obtained by oiling, film coating, cooling and winding.

Embodiment 3

[0037] Put 47.4 parts of base asphalt and 6.6 parts of base oil into the development tank and mix them, then raise the temperature to 160°C, add 30 parts of waste rubber powder and 0.04 parts of 420 rubber desulfurizer while stirring and raising the temperature, and raise the temperature to 175°C-180°C, Keep the rotation speed at 100r / min and stir for 1h. Use a colloid mill to grind one pass, then add 16 parts of talcum powder, and stir for 0.5 hours to obtain the modified asphalt material. The finished product is obtained by oiling, film coating, cooling and winding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com