A kind of preparation method of oil shale semi-coke-based composite water-retaining agent

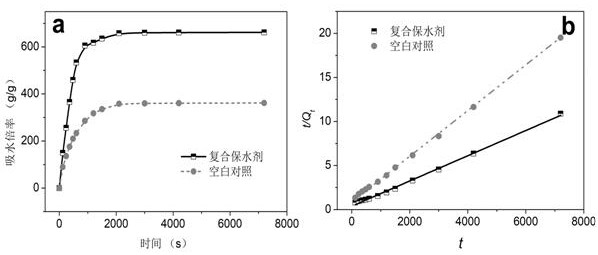

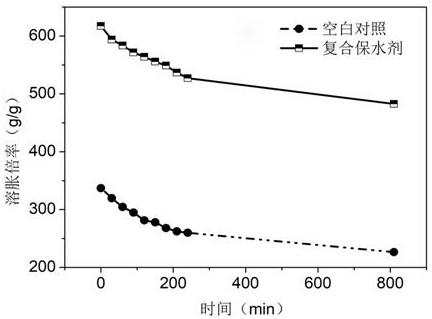

A technology of oil shale semi-coke and water-retaining agent, which is applied in chemical instruments and methods, fertilizer mixtures, applications, etc. It can solve the problems of small market demand and achieve the effects of fast swelling rate, low production cost and strong water retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

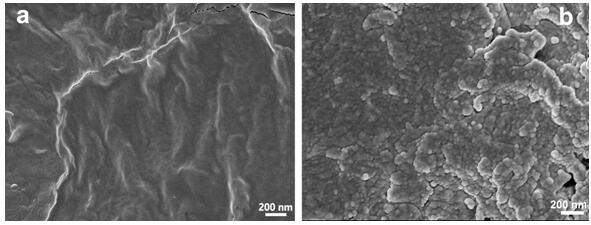

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Add 0.8 g of chitosan into 25 mL of water to form a uniform solution; then add 1 g of semi-coke powder, stir and disperse at 300 rpm for 4 hours to obtain a uniform dispersion; dissolve 0.2 g of ammonium persulfate in 5 mL of water and add dropwise, Incubate at 80°C for 15 min, then slowly add functional monomer and cross-linking agent mixture (dissolve 1g methylene bisacrylamide in 67 g acrylic acid to form a mixed solution), polymerize at 70°C for 3 h; then place Oven-dried at 105°C for 4 hours, and crushed to 200 mesh to obtain a molded composite water retaining agent. The swelling degree of the water retaining agent in pure water is 530 g / g, and the swelling degree in 0.9% sodium chloride solution is 68 g / g.

Embodiment 2

[0029]Example 2: Dissolve 4 g of sodium carboxymethylcellulose in 15 mL of water to form a homogeneous solution; then add 28 g of semi-coke powder, stir and disperse at 1000 rpm for 1 hour to obtain a homogeneous dispersion; dissolve 2.5 g of sodium persulfate in Add 5mL water dropwise, keep warm at 60°C for 5 min, then slowly add functional monomer and crosslinking agent mixture (2.5 g methylenebisacrylamide and 13 g 2-acrylamide-2-methyl-propane Dissolve sulfonic acid in 30 mL of water to form a mixed solution), polymerize at 70°C for 3 h; then place in an oven at 105°C for 4 h, and crush to 200 mesh to obtain a shaped composite water retaining agent. The swelling degree of the water retaining agent in pure water is 520 g / g, and the swelling degree in 0.9% sodium chloride solution is 74 g / g.

Embodiment 3

[0030] Example 3: Dissolve 2.5 g of guar gum in 35 mL of water to form a homogeneous solution; then add 20 g of semi-coke and disperse at 800 rpm for 1.5 h to obtain a homogeneous dispersion; dissolve 1.5 g of azobisisobutylamidine hydrochloride dissolved in 15 mL of water and added dropwise at 80 o C for 10 min, then slowly add functional monomer and cross-linking agent mixture (dissolve 1.0 g methylenebisacrylamide in a mixture of 15 g acrylic acid and 10 g styrene), and polymerize at 80 °C 4 h; then put it in an oven at 105°C for 4 h, and crush it to 200 mesh to obtain a molded composite water retaining agent. The swelling degree of the water retaining agent in pure water is 580 g / g, and the swelling degree in 0.9% sodium chloride solution is 80 g / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com