A kind of seawater-based instant fracturing fluid and preparation method thereof

A fracturing fluid and base velocity technology, applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problems of serious water production in offshore formations, limited large-scale fracturing, and high fracturing control fractures, so as to reduce costs and reduce costs. Construction risks, promotion of large-scale applications, and overall cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

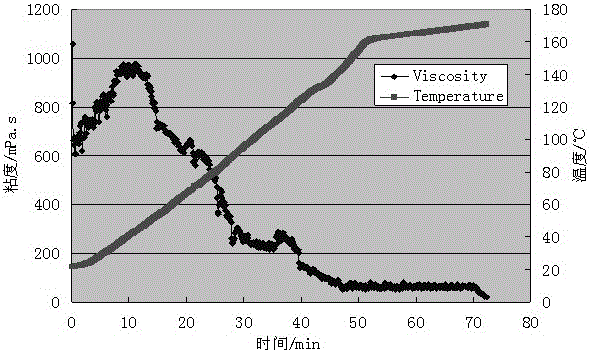

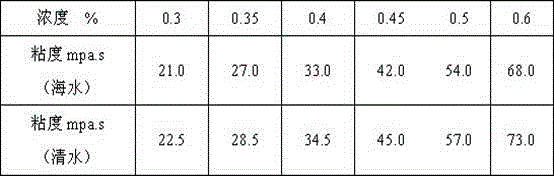

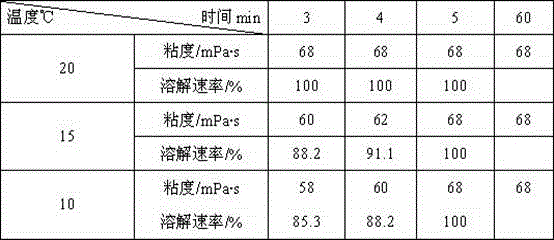

Method used

Image

Examples

Embodiment 1

[0028] A seawater-based instant fracturing fluid is composed of 97 parts of base fluid and 3 parts of cross-linking fluid; the base fluid is composed of 98.1 parts of water, 0.2 parts of thickening agent, 1.0 part of colloidal protective agent, 0.2 parts of synergist and 0.1 part of demulsification and drainage aid; the cross-linking liquid is composed of 49.6 parts of water, 50 parts of cross-linking agent and 0.4 part of gel breaker.

[0029] The preparation method of this fracturing fluid, the steps are as follows:

[0030] 1) Preparation of base liquid: Add the formula thickener, colloid protective agent, demulsification aid and synergist into the powder tank of the continuous mixing vehicle used on site, mix and pour into the formula In the water tank with a large amount of water, the mixing vehicle adjusts the powder feeding speed of the powder tank according to the construction requirements. The speed is 6-12kg / min and the suction speed of the water base material suctio...

Embodiment 2

[0040] Basically the same as Example 1, the difference is:

[0041] The fracturing fluid is composed of 97 parts of base fluid and 3 parts of crosslinking fluid; the base fluid is composed of 98.5 parts of water, 0.6 parts of thickener, 1.0 part of colloidal protective agent, 0.2 part of synergist and 0.1 part of demulsifier Drainage aid composition; The cross-linking solution is composed of 49.6 parts of water, 50 parts of cross-linking agent and 0.4 part of gel breaker.

[0042]The colloidal protective agent used in this example is an organic phosphine series scale inhibitor, specifically 2-phosphonic acid butane-1,2,4-tricarboxylic acid PBTCA; the crosslinking agent used in this example is zirconium oxychloride. What the gel breaking agent of present embodiment adopts is potassium persulfate; Described demulsification aid drainage agent is made of water, fluorocarbon surfactant FC-211, sodium dodecyl sulfate SDS, nonylphenol polyoxyethylene ether OP -10 is compounded accor...

Embodiment 3

[0044] Basically the same as Example 1, the difference is:

[0045] The fracturing fluid is composed of 97 parts of base fluid and 3 parts of cross-linking fluid; the base fluid is composed of 98.3 parts of water, 0.4 parts of thickener, 1.0 part of colloidal protective agent, 0.2 parts of synergist and 0.1 part of Composition of demulsification and drainage aids; the cross-linking liquid is composed of 49.6 parts of water, 50 parts of cross-linking agent and 0.4 part of gel breaker.

[0046] The colloidal protective agent used in this example is a polycarboxylic acid scale inhibitor dispersant, specifically polyepoxysuccinic acid (sodium) PESA; the crosslinking agent used in this example is tetrabutyl zirconate. The breaker used in the present embodiment is ammonium persulfate; the demulsification and drainage aid is composed of water, fluorocarbon surfactant FC-211, sodium dodecyl sulfate SDS, nonylphenol polyoxyethylene ether OP -10 is compounded according to the mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com