Method and device for treating liquid sulfur tank tail gas

A technology of tail gas treatment and liquid sulfur pool, which is applied to the device implementing the method, tail gas purification of liquid sulfur pool, and multi-stage desulfurization purification field, which can solve the problems of low cost of the device, unusable use, and easy solidification and blockage of liquid sulfur droplets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

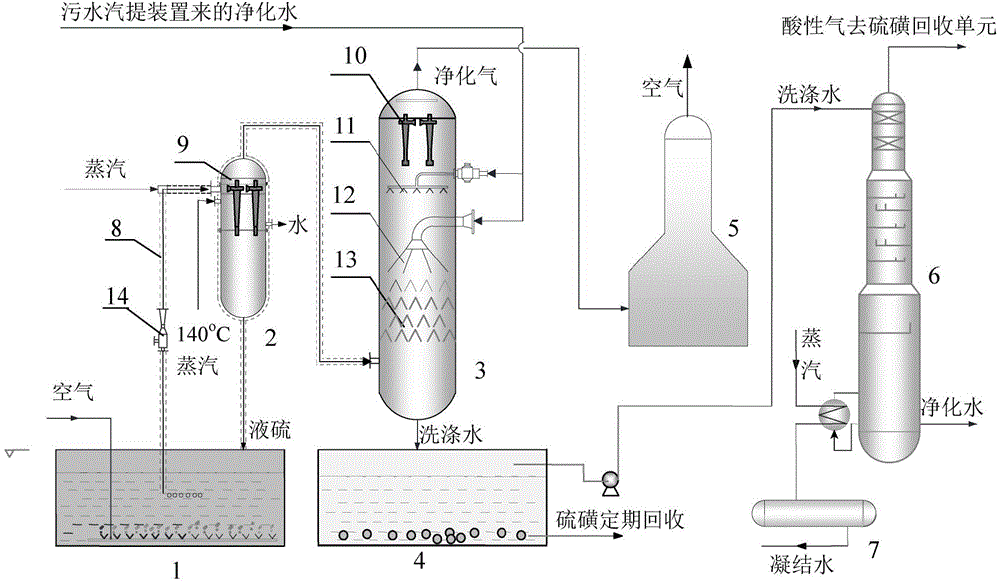

[0078] Embodiment 1: The method of the present invention is applied to 150,000 tons / year of sulfur in a branch of Sinopec Co., Ltd. Liquid sulfur tank tail gas desulfurization system

[0079] 1. Process flow

[0080] Such as figure 1 As shown, the tail gas of the liquid sulfur pool entrains sulfur powder, sulfur droplets, and gases such as hydrogen sulfide, sulfur dioxide, and sulfur mist, and more than 80% of the sulfur exists in the form of sulfur powder and liquid sulfur, while the sulfur in hydrogen sulfide and sulfur dioxide gas Accounting for only 20%, the total content of hydrogen sulfide and sulfur dioxide is 500ppm.

[0081] 2. Key equipment

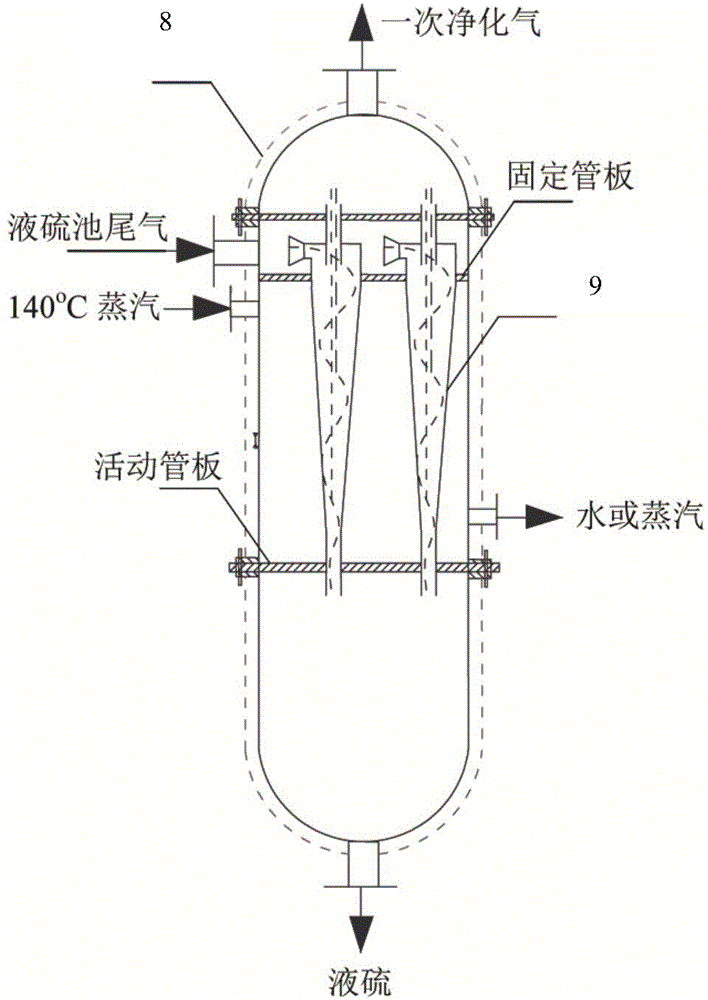

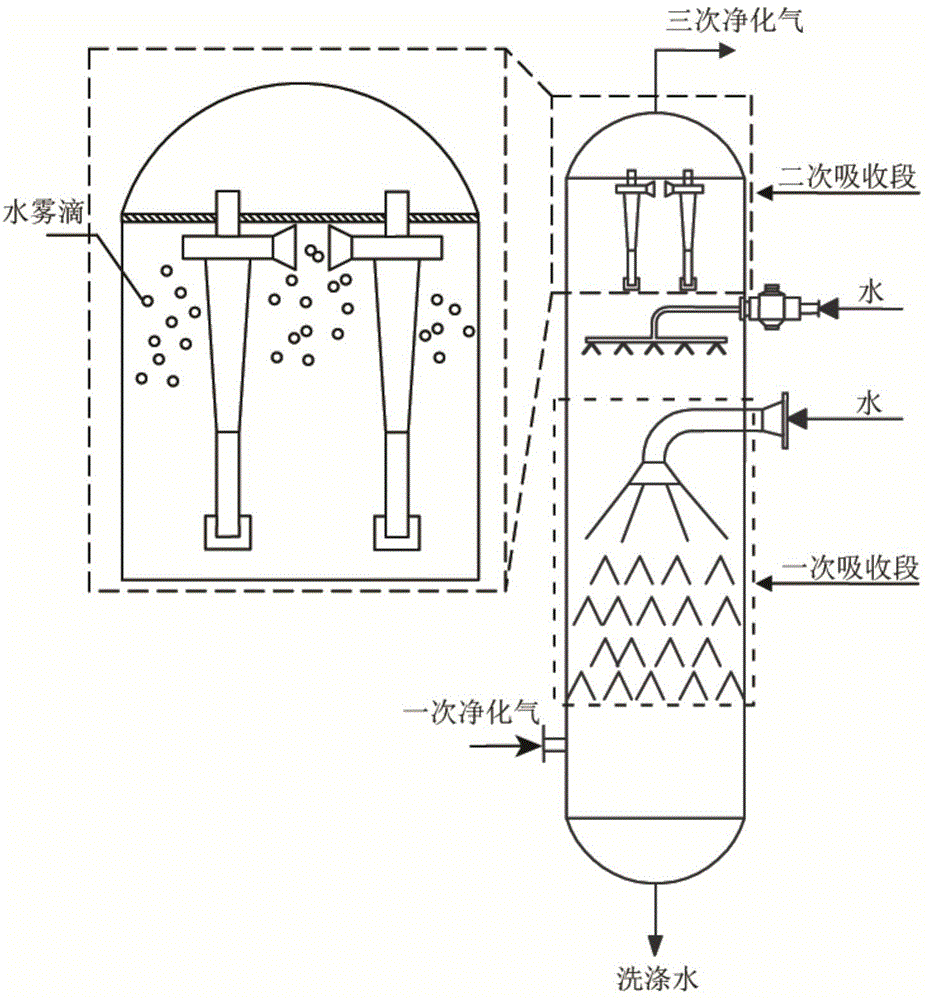

[0082] The key equipment in this process is the heat exchange swirl tank containing the heat exchange swirl core tube and the swirl absorption tower integrating "herringbone" tray, liquid distributor, atomizer and swirl absorber. . Among them, the heat exchange swirl core tube and the swirl absorber are composed of a swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com