Efficient heterojunction solar cell and preparation method thereof

A solar cell and heterojunction technology, which is applied in the field of solar cells, can solve the problems of increased loading and unloading and handling labor, high cell manufacturing costs, cumbersome process flow, etc., and achieves improved cell yield, concentrated efficiency distribution, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

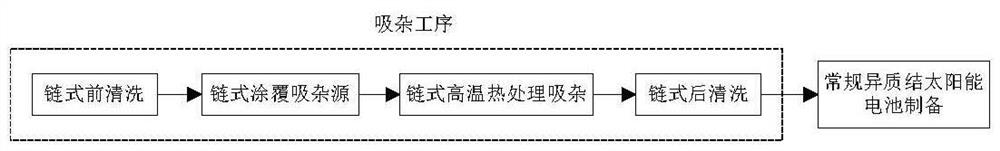

[0043] A method for preparing a high-efficiency heterojunction solar cell, specifically comprising the following steps:

[0044] (1) Full-chain gettering for N-type silicon wafers, including:

[0045] Chain-type pre-cleaning: Silicon wafers are transported by conveyor rollers into the chain-type pre-cleaning functional area, first cleaned by NaOH solution with a concentration of 1% by mass percentage, washed with water, and then cleaned by HF solution with a concentration of 5% by mass percentage, washed with water and then baked Dry, used to remove organic matter, damaged layer, metal impurities and oxide layer on the surface of the silicon wafer;

[0046] Chain coating gettering source: After drying, the silicon wafer is transported into the functional area of the chain coating gettering source through the conveying roller. The phosphorus-containing slurry on the surface of the silicon wafer is evenly coated, and the excess phosphorus-containing slurry is removed, and dri...

Embodiment 2

[0055] A method for preparing a high-efficiency heterojunction solar cell, specifically comprising the following steps:

[0056] (1) Full-chain gettering for N-type silicon wafers, including:

[0057] Chain pre-cleaning: Silicon wafers are transported by conveyor rollers into the chain pre-cleaning functional area, first cleaned by KOH solution with a concentration of 1% by mass percentage, washed with water, and then cleaned by HF solution with a concentration of 1% by mass percentage, washed with water and then baked Dry, used to remove organic matter, damaged layer, metal impurities and oxide layer on the surface of the silicon wafer;

[0058] Chain coating gettering source: After drying, the silicon wafer is transported into the functional area of the chain coating gettering source by the conveyor roller. The surface of the silicon wafer is coated with a layer of phosphoric acid solution through the coating device, and the silicon wafer is squeezed by the conveyor roller t...

Embodiment 3

[0067] A method for preparing a high-efficiency heterojunction solar cell, specifically comprising the following steps:

[0068] (1) Full-chain gettering for N-type silicon wafers, including:

[0069] Chain-type pre-cleaning: Silicon wafers are transported into the chain-type pre-cleaning functional area by conveying rollers, firstly cleaned by NaOH solution with a concentration of 3% by mass percentage, washed with water, and then washed by HF solution with a concentration of 10% by mass percentage, washed with water and then baked Dry, used to remove organic matter, damaged layer, metal impurities and oxide layer on the surface of the silicon wafer;

[0070] Chain-type coating gettering source: After drying, the silicon wafer is transported into the functional area of the chain-type coating gettering source through the conveying roller. The boron-containing slurry on the surface of the silicon wafer is evenly coated, the excess boron-containing slurry is removed, and drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com