Method for directly purifying gold from silver anode slime through wet method comprehensive recovery

A silver anode slime, direct technology, applied in the field of wet comprehensive recovery of silver anode slime to directly purify gold, can solve the problems of capital backlog in the production cycle, etc., and achieve the effect of short process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Material composition: gold: 31.33%, silver: 36.04%, palladium: 0.26%;

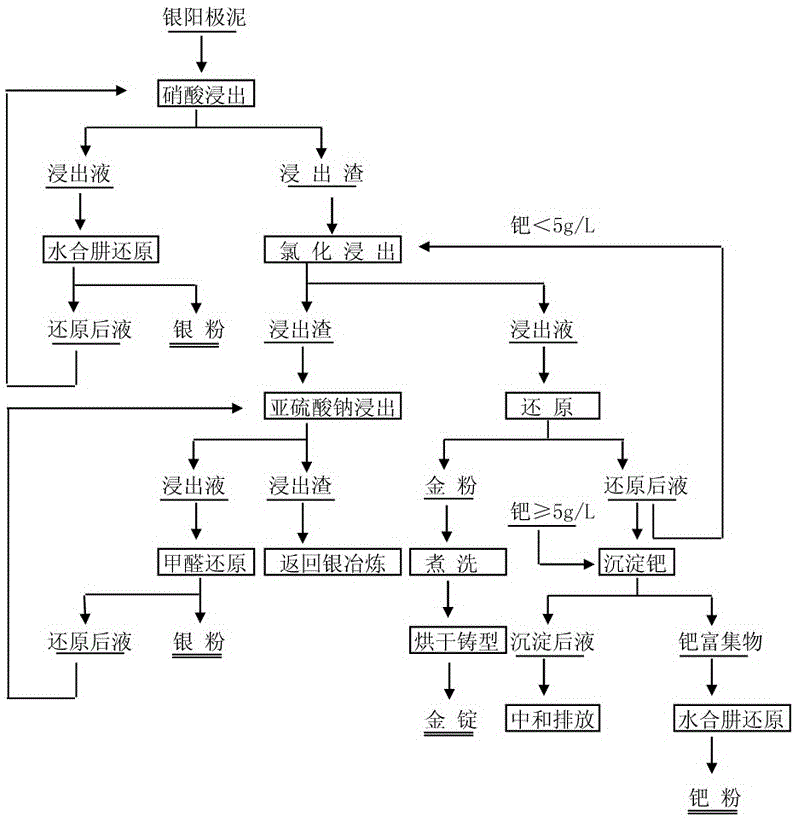

[0025] The implementation of this material adopts the production process such as figure 1 , take 100g of material in nitric acid solution with a mass concentration of 40%, in a 2L laboratory acid-resistant reactor, the liquid-solid volume mass ratio is 5:1 mL / g, the temperature is 70°C, the reaction time is 5h, and after the reaction is completed, cool and filter , slowly add 15g of hydrazine hydrate to the reaction solution, the temperature is 35°C, react for 2 hours, and filter to obtain silver powder. Take the above leaching residue at a liquid-solid volume mass ratio of 6:1 mL / g, hydrochloric acid concentration of 120g / L, sodium chlorate addition of 15g / L, temperature 80°C, and filter after 4 hours of reaction to obtain the chlorinated leaching residue Silver powder was obtained through sodium sulfite leaching and formaldehyde reduction, and 30% lye was slowly added to the chlorination leach so...

Embodiment 2

[0029] Material composition: gold: 37.56%, silver: 41.28%, palladium: 1.37%;

[0030] The implementation of this material adopts the production process such as figure 1 , take 100g of material in nitric acid solution with a mass concentration of 45%, in a 2L laboratory acid-resistant reactor, the liquid-solid volume mass ratio is 5:1 mL / g, the temperature is 75°C, the reaction time is 6h, and after the reaction is completed, cool and filter , slowly add 20g of hydrazine hydrate to the reaction solution, the temperature is 40°C, react for 2 hours, and filter to obtain silver powder. Take the above leaching residue at a liquid-solid volume mass ratio of 5:1 mL / g, hydrochloric acid concentration of 130g / L, sodium chlorate addition of 17g / L, temperature 85°C, and filter after 5 hours of reaction to obtain the chlorinated leaching residue Silver powder was obtained through sodium sulfite leaching and formaldehyde reduction, and 30% lye was slowly added to the chlorination leach so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com