Lithium iron phosphate-based composite positive electrode material as well as preparation method and application thereof

A composite cathode material, lithium iron phosphate technology, applied in battery electrodes, electrical components, electrochemical generators and other directions, can solve the problems of low efficiency, complex and cumbersome graphene synthesis process, and long composite material process, and achieve high process efficiency. , Shorten the synthetic process route, and the effect of good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

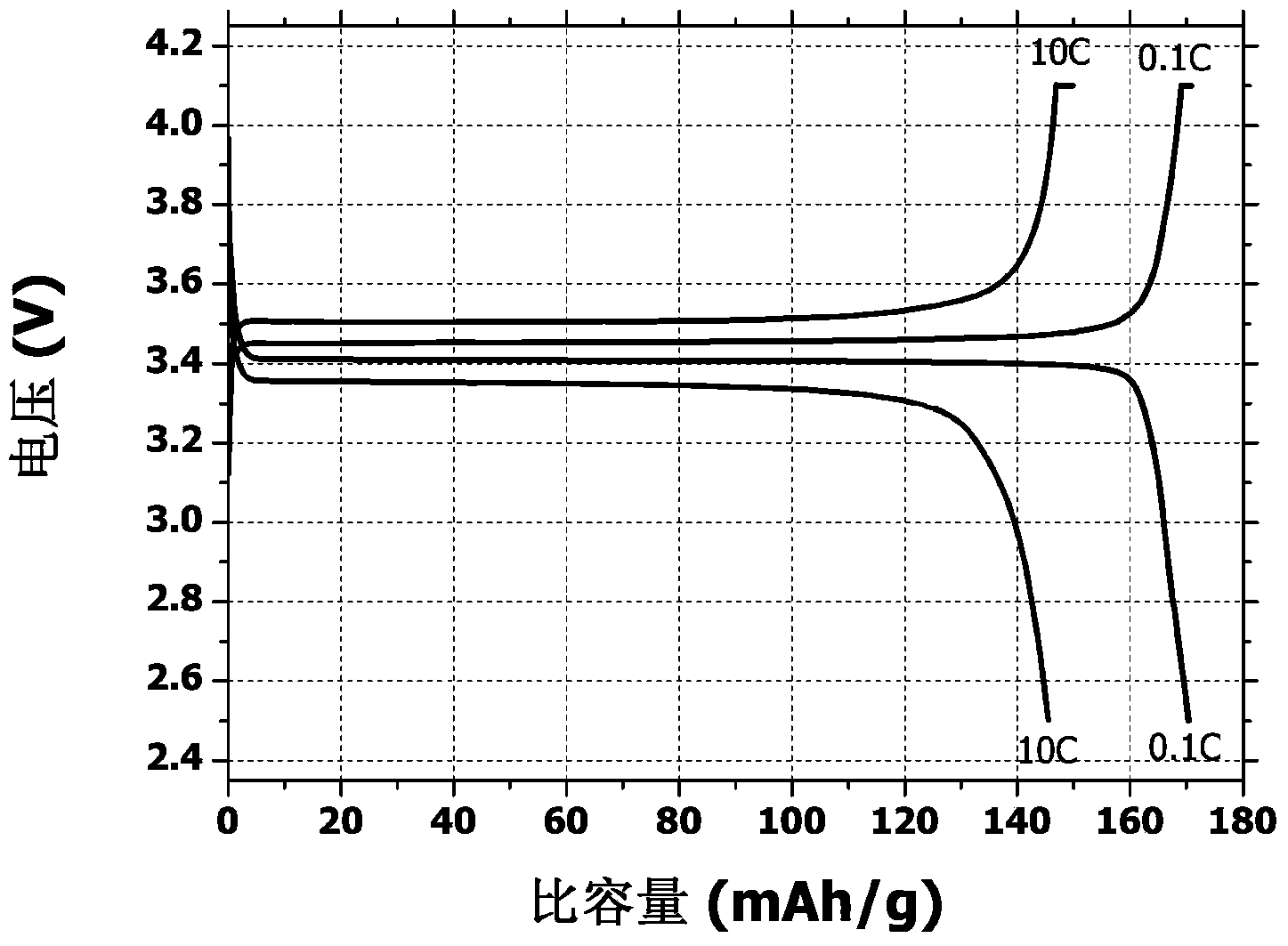

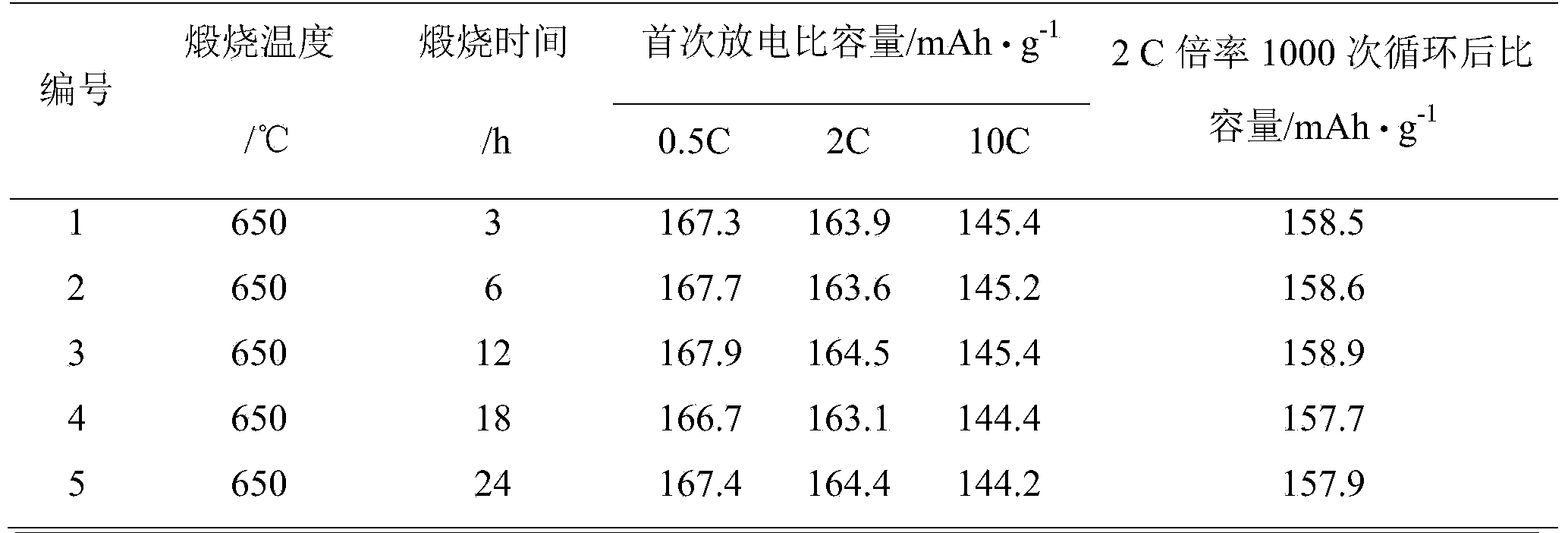

[0027] a kind of like figure 1 The lithium iron phosphate-based composite positive electrode material of the present invention is shown. The composite positive electrode material is mainly composed of lithium iron phosphate and graphene. Crystal, lithium iron phosphate is obtained by converting its precursor, and the precursor of lithium iron phosphate nanocrystal and graphene are simultaneously synthesized through one reaction.

[0028]The preparation method of the lithium iron phosphate-based composite positive electrode material of this embodiment comprises the following steps: mixing lithium oxalate, ferrous oxalate and ammonium dihydrogen phosphate according to the stoichiometric ratio, and then adding nanoscale scales with 15% of the weight of the mixture to the mixture Graphite (the average particle size is about 100nm), adding ethanol as a dispersant, adding fatty alcohol polyoxyethylene ether ammonium sulfate as a foaming agent, and performing high-energy ball milling...

Embodiment 2

[0033] A lithium iron phosphate-based composite positive electrode material of the present invention, the composite positive electrode material is mainly composed of lithium iron phosphate and graphene, the graphene is uniformly dispersed in lithium iron phosphate, and the film formed by graphene is evenly wrapped around lithium iron phosphate nanometer Crystal, lithium iron phosphate is obtained by converting its precursor, and the precursor of lithium iron phosphate nanocrystal and graphene are simultaneously synthesized through one reaction.

[0034] The preparation method of the lithium iron phosphate-based composite positive electrode material in this embodiment comprises the following steps: mixing lithium oxalate, ferrous oxalate and ammonium dihydrogen phosphate according to the stoichiometric ratio, and then adding 0.5% of the mass of the mixture to the mixture of nanoscale scales Graphite (with a diameter of 500nm), adding ethylene glycol as a dispersant, adding rosin...

Embodiment 3

[0039] A lithium iron phosphate-based composite positive electrode material of the present invention, the composite positive electrode material is mainly composed of lithium iron phosphate and graphene, the graphene is uniformly dispersed in lithium iron phosphate, and the film formed by graphene is evenly wrapped around lithium iron phosphate nanometer Crystal, lithium iron phosphate is obtained by converting its precursor, and the precursor of lithium iron phosphate nanocrystal and graphene are simultaneously synthesized through one reaction.

[0040] The preparation method of the lithium iron phosphate-based composite positive electrode material of this embodiment comprises the following steps: mixing lithium oxalate, ferrous oxalate and ammonium dihydrogen phosphate according to the stoichiometric ratio, and then adding nano-scale scales of 8% by weight of the mixture to the mixture Graphite (with a diameter of 200nm), add acetone as a dispersant, add ammonium lauryl sulfat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com