Matte varnish and preparation method thereof

A clear topcoat and topcoat technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems that the degree of crosslinking cannot be designed too high, the paint film becomes yellow and aging, and the hardness is difficult to increase, so as to achieve high hardness, Easy to spray, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

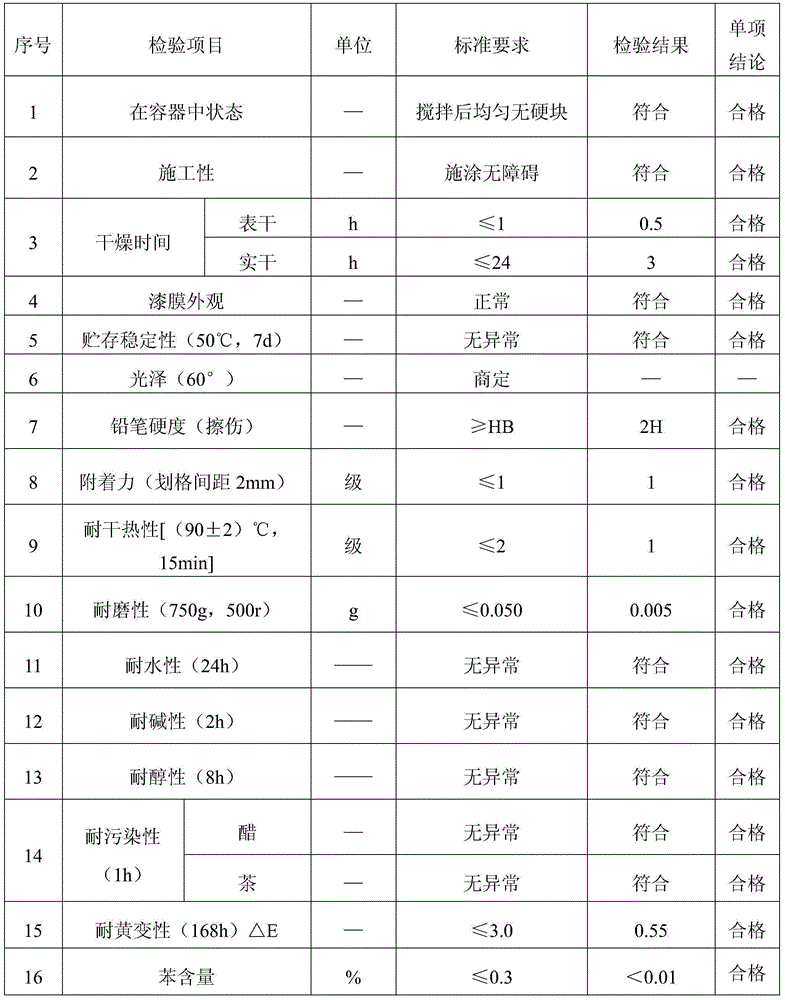

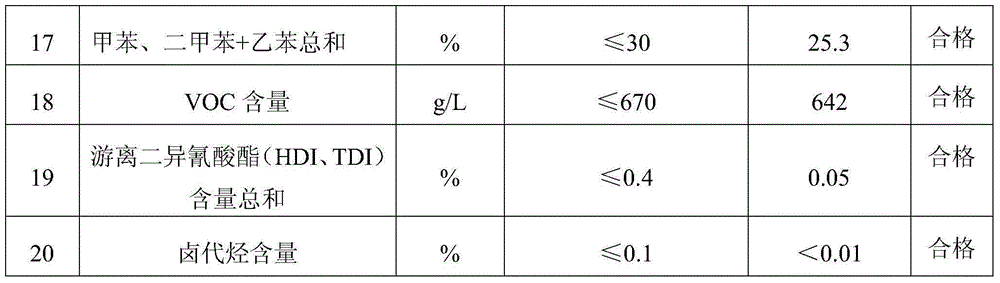

Examples

Embodiment 1

[0030] Cellulose acetate solution: 20% cellulose acetate, 20% methyl ethyl ketone and 60% butyl acetate;

[0031] Component A: 75% acrylic resin, 1% dispersant, 1.5% polyethylene wax slurry, 1% polyamide wax slurry, 1% leveling agent EFKA-3777, 0.2% leveling agent EFKA -3600, 0.1% defoamer, 3% methyl isobutyl ketone, 0.5% wax powder, 4.2% matting powder, 2.5% butyl acetate, 1% UV absorber, 1% Light stabilizer and 8% cellulose acetate solution;

[0032] Component B: 55% dehydrated butyl acetate and 45% HDI trimer curing agent HX-R;

[0033] Component C: 40% xylene, 25% butyl acetate, 15% propylene glycol methyl ether acetate, 10% mesitylene and 10% cyclohexanone.

[0034] Follow the steps below to prepare a matte clear finish:

[0035] 1) Preparation of cellulose acetate solution: mix cellulose acetate, methyl ethyl ketone, and butyl acetate, then disperse and stir until the fineness is ≤15um;

[0036] 2) Preparation of Component A: Select a clean dispersion cylinder that m...

Embodiment 2

[0042] Cellulose acetate solution: 20% cellulose acetate, 20% methyl ethyl ketone and 60% butyl acetate;

[0043] Component A: 85% acrylic resin, 0.6% dispersant, 1% polyethylene wax slurry, 0.5% polyamide wax slurry, 0.5% leveling agent EFKA-3777, 0.05% leveling agent EFKA -3600, 0.05% defoamer, 2% methyl isobutyl ketone, 0.3% wax powder, 2.5% matting powder, 1.5% butyl acetate, 0.5% UV absorber, 0.5% Light stabilizer and 5% cellulose acetate solution;

[0044] Component B: 50% dehydrated butyl acetate and 50% HDI trimer curing agent 3390;

[0045] Component C: 35% xylene, 20% butyl acetate, 20% propylene glycol methyl ether acetate, 15% mesitylene and 10% cyclohexanone.

[0046] Follow the steps below to prepare a matte clear finish:

[0047] 1) Preparation of cellulose acetate solution: mix cellulose acetate, methyl ethyl ketone, and butyl acetate, then disperse and stir until the fineness is ≤15um;

[0048] 2) Preparation of Component A: Select a clean dispersion cylin...

Embodiment 3

[0054] Cellulose acetate solution: 20% cellulose acetate, 20% methyl ethyl ketone and 60% butyl acetate;

[0055] Component A: 79.7% acrylic resin, 0.8% dispersant, 1.2% polyethylene wax slurry, 0.8% polyamide wax slurry, 0.8% leveling agent EFKA-3777, 0.1% leveling agent EFKA -3600, 0.1% defoamer, 2.5% methyl isobutyl ketone, 0.4% wax powder, 3% matting powder, 2% butyl acetate, 0.8% UV absorber, 0.8% Light stabilizer and 7% cellulose acetate solution;

[0056] Component B: 53% dehydrated butyl acetate and 47% HDI trimer curing agent 3390;

[0057] Component C: 39% xylene, 23% butyl acetate, 19% propylene glycol methyl ether acetate, 14% mesitylene and 5% cyclohexanone.

[0058] Follow the steps below to prepare a matte clear finish:

[0059] 1) Preparation of cellulose acetate solution: mix cellulose acetate, methyl ethyl ketone, and butyl acetate, then disperse and stir until the fineness is ≤15um;

[0060] 2) Preparation of Component A: Select a clean dispersion cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com