High-solid chrome-free acrylic polyurethane finish paint

An acrylic polyurethane, high-solid technology, applied in the field of coatings, can solve problems such as inability to meet requirements, and achieve the effects of low volatile organic compounds, high decorative properties, and high initiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A high solids chrome-free acrylic polyurethane topcoat made by mixing components A and B in a ratio of 100:25.

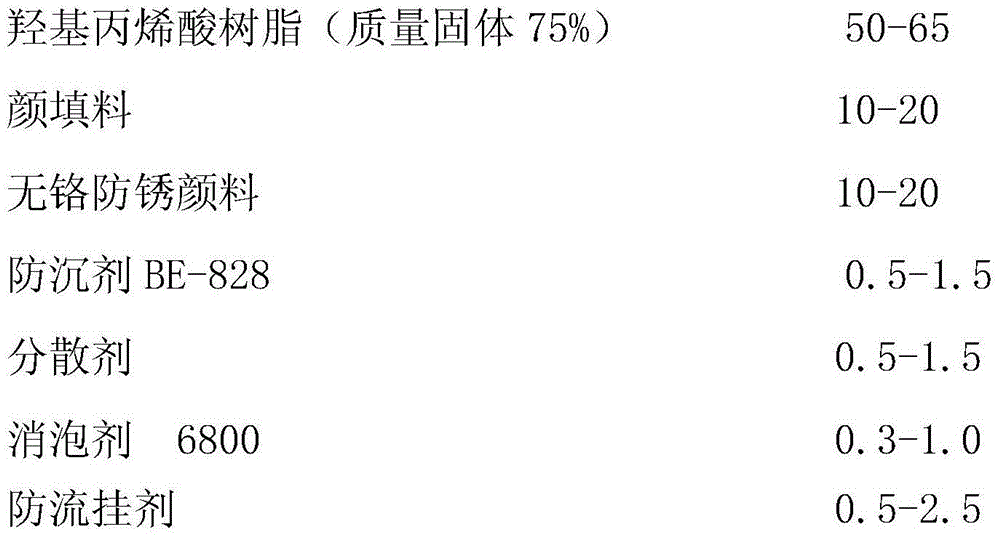

[0029] Among them, the first component is composed of the following components:

[0030] Self-made tertiary carbonic acid glycidyl ester modified high solid

[0031]

[0032]

[0033] Component B is calculated in parts by weight: 50Kg of aliphatic diisocyanate and 30Kg of butyl acetate.

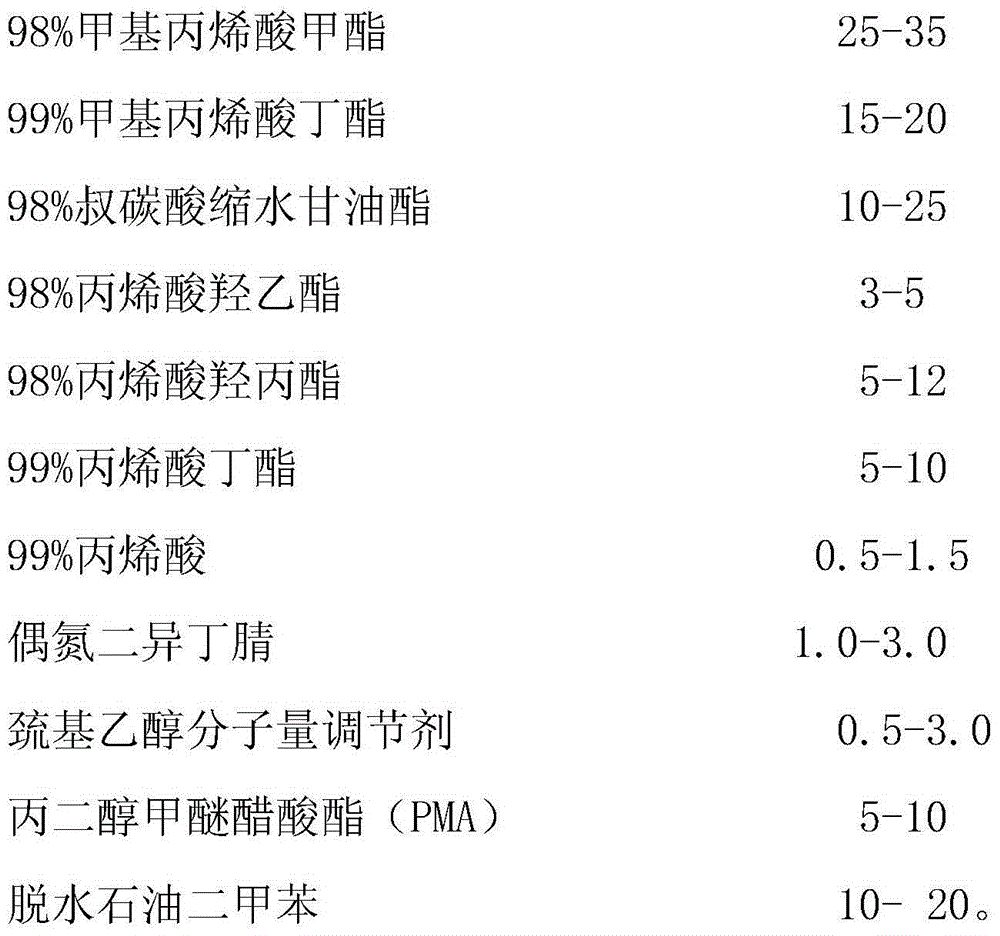

[0034] The self-made tertiary carbonic acid glycidyl ester modified high-solid hydroxyl acrylic resin (mass solid 75%) consists of the following components:

[0035]

[0036] The preparation method of the above-mentioned self-made tertiary carbonic acid glycidyl ester modified high-solid hydroxyl acrylic resin (mass solid 75%) is carried out according to the following steps,

[0037] ⑴ Add methyl methacrylate, butyl methacrylate, hydroxyethyl acrylate, hydroxypropyl acrylate, butyl acrylate, and acrylic acid to the dripping tank according to the formula amount, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com