Coating for sandwich panel and board two-used colorful steel plates and method of use thereof

A technology for color-coated steel plates and sandwich panels, used in polyester coatings, multi-color effect coatings, polyurea/polyurethane coatings, etc., can solve problems such as weak long-term use performance, and achieve stable performance, uniform coating, and corrosion resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

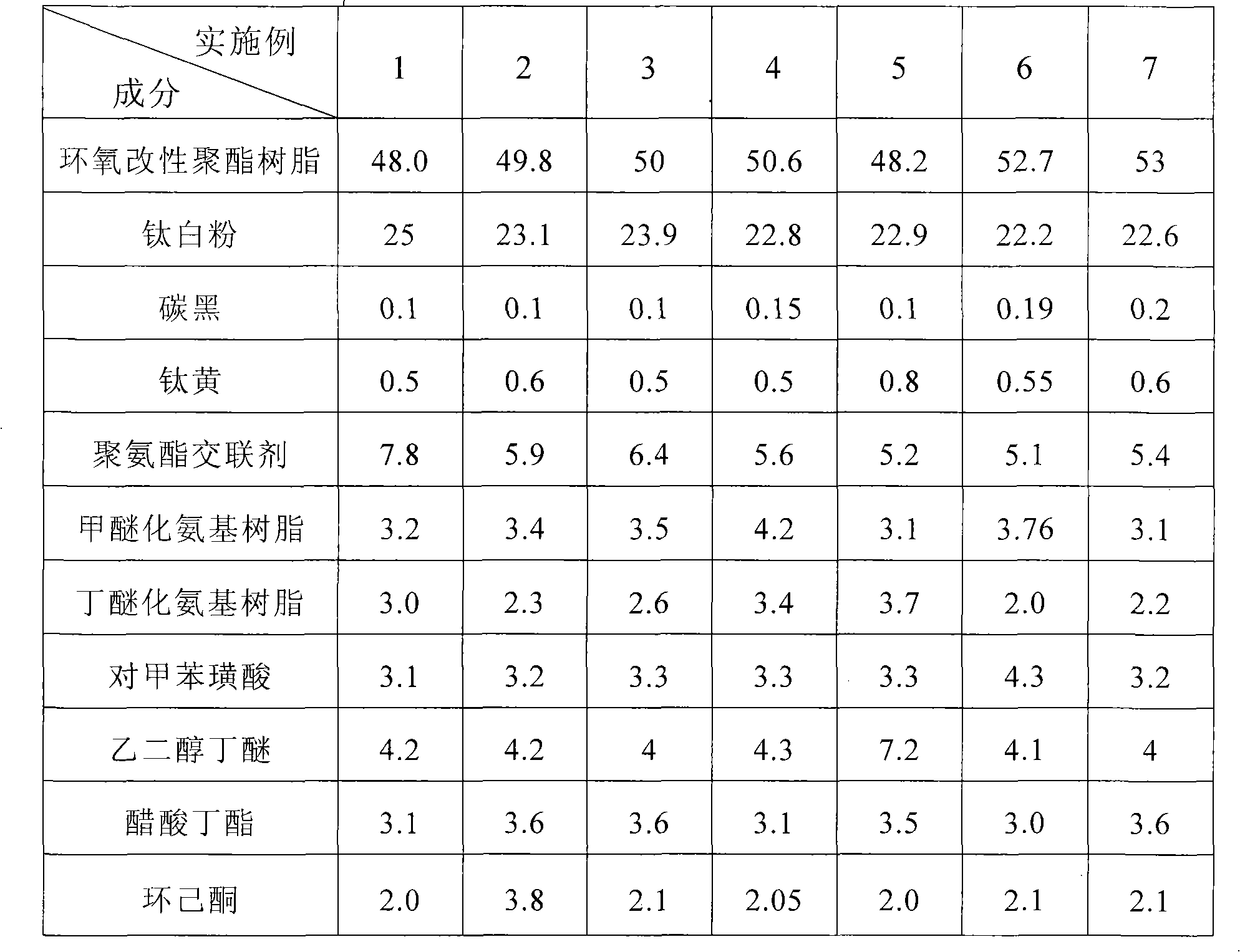

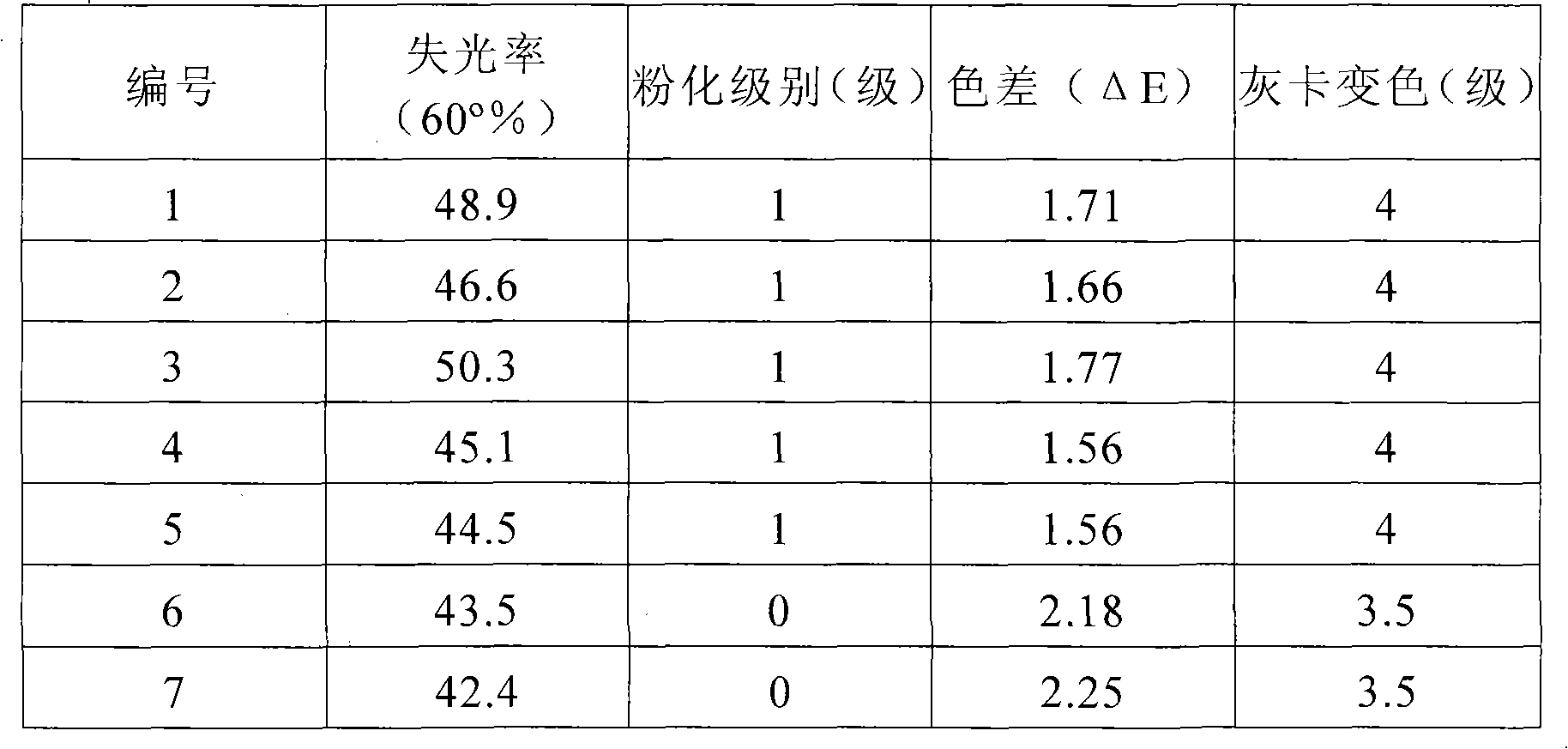

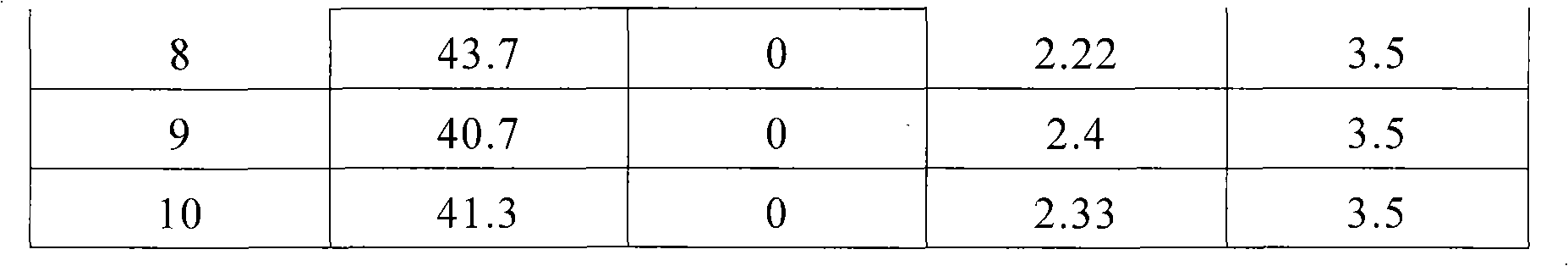

[0056] See Table 1 for examples of the present invention.

[0057] Table 1 Unit: mass percentage

[0058]

[0059] Production process: pretreatment-primary coating back coating-primary coating baking-primary coating cooling-finish coating back coating-finish coating baking-finish coating cooling;

[0060] Sandwich panel of the present invention, the coating method of double-purpose prepainted steel plate of veneer, comprises the following steps:

[0061] 1) Pretreatment and cleaning;

[0062] 2) Front side coating,

[0063] 2.1 Initial coating, coating viscosity (4#ZN cup): 9-18 seconds, coating roller speed: strip steel speed + (8-25) m / min, belt material roller speed: strip steel speed × (0.40-0.60 ), coating roller / belt roller pressure: 1400~2000MPA;

[0064] 2.2 Initial coating baking: baking temperature: 232-249°C, time 18-24 seconds;

[0065] 2.3 Initial coating cooling: water cooling, cooling to room temperature;

[0066] 2.4 Fine coating, coating viscosity (4#...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com