Method for purifying acrylic acid

A technology of acrylic acid and acetic acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., which can solve the problems of increasing the difficulty and complexity of extraction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

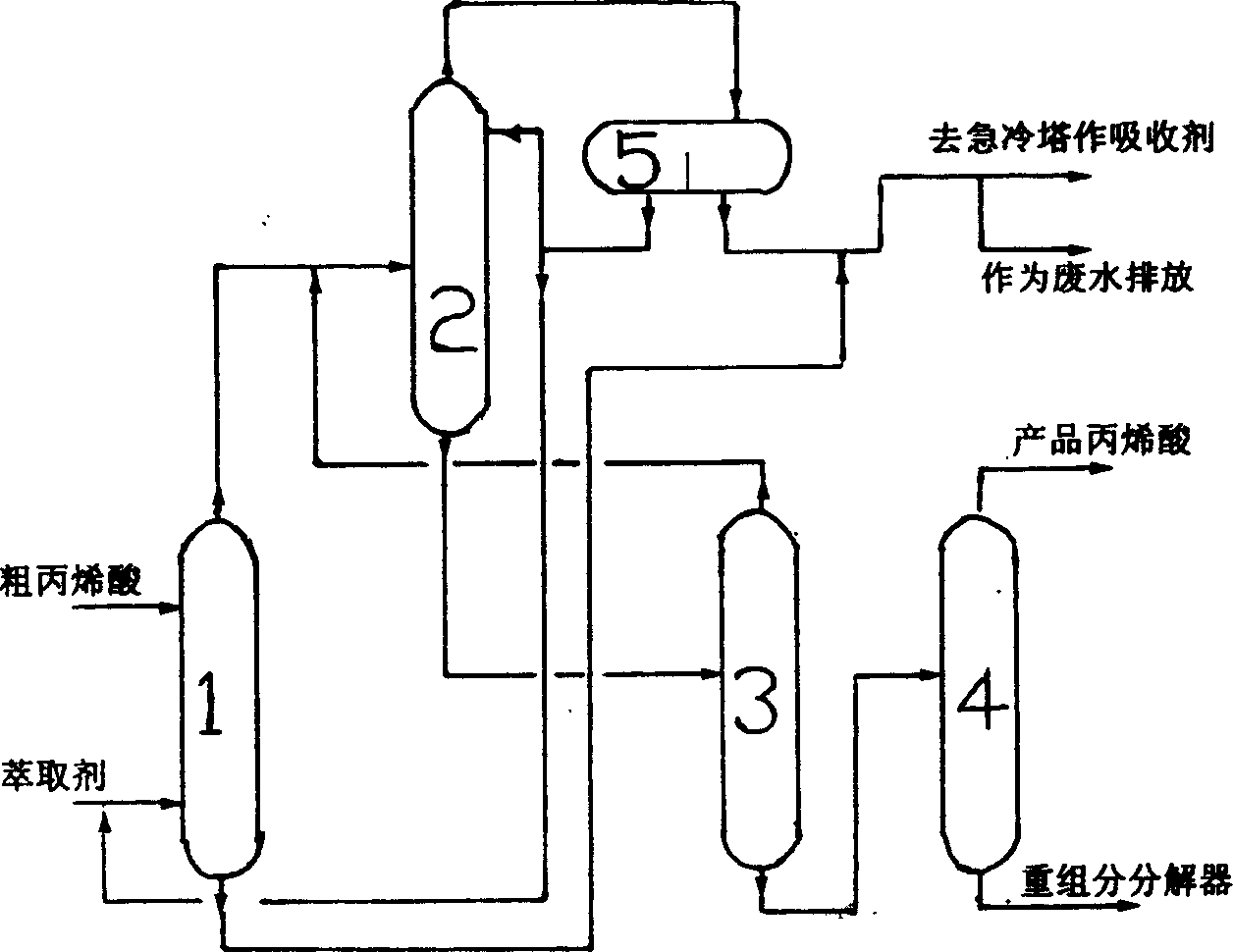

Method used

Image

Examples

Embodiment 1

[0017] Table 1 Extraction effect of each extractant

[0018] No. Extractant Extractant / crude acrylic acid solution (mass ratio) Extraction rate (wt%)

[0019] 1 Isobutyl acetate 1:1 95.55

[0020] 2 isopropyl ether 1:1 94.00

[0021] 3 butyl acetate 1:1 93.98

[0022] 4 Propyl acetate 1:1 93.56

[0023] 5 toluene 1:1 58.58

[0024] As can be seen from Table 1, in the single extractant tested, the extraction effect of isobutyl acetate is the best. Isopropyl ether is next, and butyl acetate is third.

Embodiment 2

[0026] Table 2 Extraction effect of compound extractant

[0027] No. Extractant Extractant / crude acrylic acid solution (mass ratio) Extraction rate (wt%)

[0028] 1 toluene / isobutyl acetate 3:1 98.48

[0029] 2 toluene / butyl acetate 3:1 98.25

[0030] 3 toluene / isopropyl acetate 3:1 97.24

[0031] It can be seen from Table 2 that among the tested compound extractants, the extraction effect of toluene / isobutyl acetate is the best, and the extraction rate can reach 98.48%, which is better than the extraction effect of toluene / butyl acetate.

Embodiment 3

[0033] Table 3 Extraction effect of extractant under different extraction ratio

[0034] Toluene: isobutyl acetate: crude acrylic acid solution (mass ratio) extraction rate (wt%)

[0035] 2:1:1 87.50

[0036] 1.5:1.5:1 96.63

[0037] 1:2:1 98.48

[0038] As can be seen from Table 3, when the extraction ratio is 1:2:1, the extraction effect of toluene / isobutyl acetate is the best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com