Anti-static multifunctional thin film and preparation method thereof

An anti-static, multi-functional technology, applied in the field of anti-static multi-functional film and its preparation, can solve the problem of damage to circuit boards, etc., and achieve the effect of long-lasting performance, high strength, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

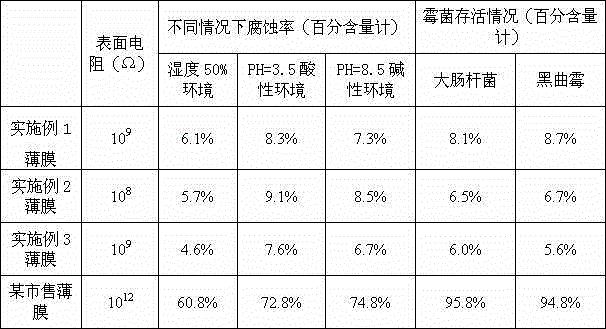

Examples

Embodiment 1

[0038] The antistatic multifunctional film in this embodiment is composed of the following components in parts by mass: 36 parts of PC resin, 38 parts of polyvinyl chloride resin, 34 parts of polythiophene, 38 parts of polyethylene glycol, and 34 parts of polyphenylene vinylene 34 parts, 34 parts of diethylene glycol terephthalate, 40 parts of permethrin, 34 parts of polyethylene grafted maleic anhydride, 38 parts of triphenyl phosphite, 34 parts of polytetramethylene ether glycol, anti 38 parts of electrostatic masterbatch, 34 parts of tetrathiotetracene, 38 parts of polyarylether nitrile, 34 parts of octenyl succinic acid starch ester, 38 parts of polylactic acid, 34 parts of calcium zinc composite stabilizer, erucamide fluorescent powder 38 parts, 34 parts of butyl acetate, 38 parts of lubricant.

[0039] The steps of the above-mentioned antistatic multifunctional film preparation method are as follows:

[0040] (1) The PC resin, polyvinyl chloride resin, polythiophene, po...

Embodiment 2

[0045] The antistatic multifunctional film in this embodiment is composed of the following components in parts by mass: 38 parts of PC resin, 40 parts of polyvinyl chloride resin, 36 parts of polythiophene, 40 parts of polyethylene glycol, 36 parts of polyphenylene vinylene 36 parts, 36 parts of diethylene glycol terephthalate, 42 parts of permethrin, 36 parts of polyethylene grafted maleic anhydride, 40 parts of triphenyl phosphite, 36 parts of polytetramethylene ether glycol, anti 40 parts of electrostatic masterbatch, 36 parts of tetrathiotetracene, 40 parts of polyarylether nitrile, 36 parts of octenyl succinic acid starch ester, 40 parts of polylactic acid, 36 parts of calcium zinc composite stabilizer, erucamide fluorescent powder 40 parts, 36 parts of butyl acetate, 40 parts of lubricant.

[0046] The steps of the above-mentioned antistatic multifunctional film preparation method are as follows:

[0047] (1) The PC resin, polyvinyl chloride resin, polythiophene, polyet...

Embodiment 3

[0052] The antistatic multifunctional film in this embodiment is composed of the following components in parts by mass: 40 parts of PC resin, 42 parts of polyvinyl chloride resin, 38 parts of polythiophene, 42 parts of polyethylene glycol, and 38 parts of polyphenylene vinylene 38 parts, 38 parts of diethylene glycol terephthalate, 44 parts of permethrin, 38 parts of polyethylene grafted maleic anhydride, 42 parts of triphenyl phosphite, 38 parts of polytetramethylene ether glycol, anti 42 parts of electrostatic masterbatch, 38 parts of tetrathiotetracene, 42 parts of polyarylether nitrile, 38 parts of octenyl succinic acid starch ester, 42 parts of polylactic acid, 38 parts of calcium zinc composite stabilizer, erucamide fluorescent powder 42 parts, 38 parts of butyl acetate, 42 parts of lubricant.

[0053] The steps of the above-mentioned antistatic multifunctional film preparation method are as follows:

[0054] (1) The PC resin, polyvinyl chloride resin, polythiophene, po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com