Gasoline and diesel oil additive with power-increasing and energy-saving function

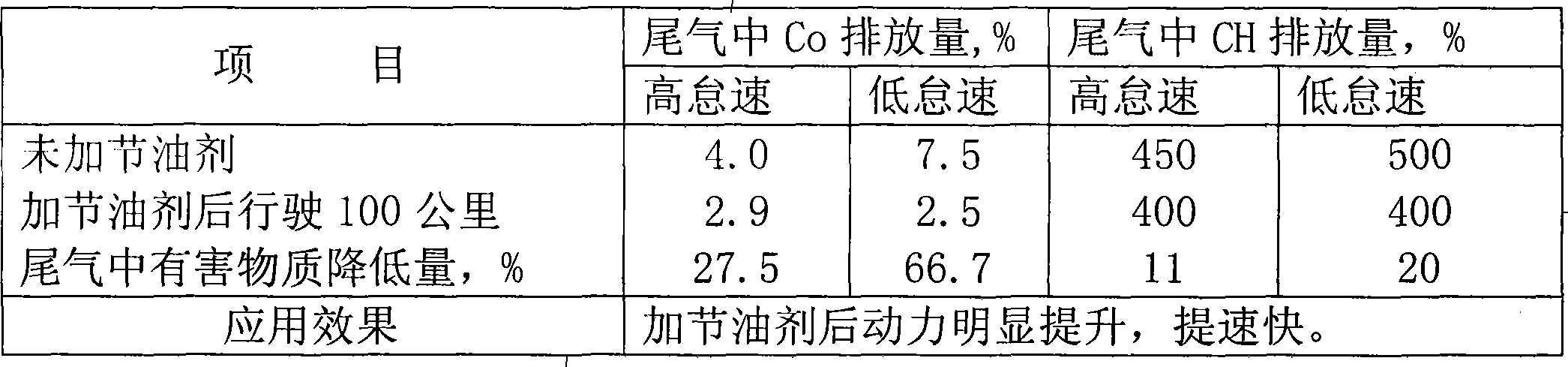

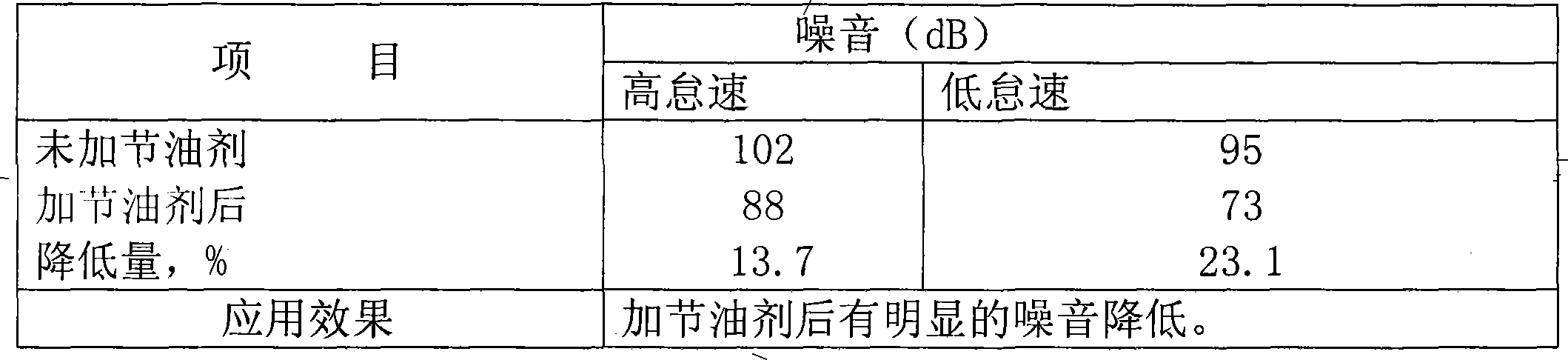

A technology of additives and gasoline, which is applied in the field of engine fuel gasoline, diesel additives, and vehicle fuel additives. It can solve the problems of unobvious reduction of exhaust emissions, metal corrosion, and high cost, so as to avoid harmful gases and black smoke and optimize operation. Conditions, the effect of improving the power function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

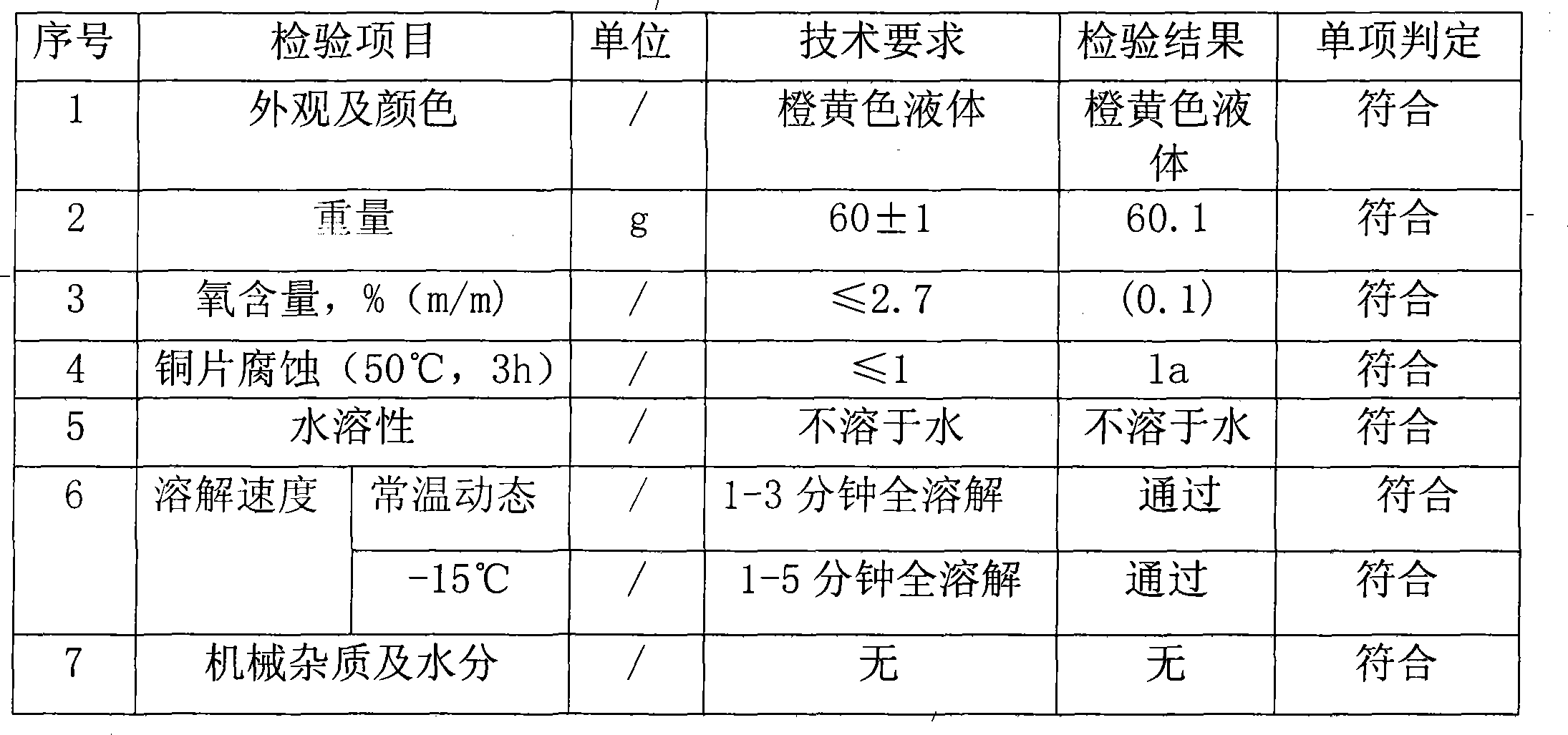

Examples

Embodiment 1

[0037] At room temperature, mix 20g of hydrogenated vegetable oil triglyceride, 3g of biolipase, 180g of dimethylformamide, and 600g of butyl acetate, and stir at 20±5°C. After stirring evenly, the desired finished product is obtained.

Embodiment 2

[0039] At room temperature, mix 30g of hydrogenated vegetable oil triglyceride, 5g of biological lipase, 200g of dimethylformamide, and 650kg of butyl acetate, stir at 20±5°C, and get the desired finished product after stirring evenly.

Embodiment 3

[0041] At room temperature, mix 40g of hydrogenated vegetable oil triglyceride, 4g of biolipase, 210g of dimethylformamide, and 700g of butyl acetate, and stir evenly at 20±5°C, then add 0.1g of oil soluble color to obtain the desired finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com