Fireproof silicon rubber wallpaper

A technology of silicone rubber and silicone rubber layer, applied in the field of decorative materials, can solve the problems of easy to produce mildew, not easy to scrub, not resistant to stains, etc., and achieve the effects of not easily adhering to stains, improving smoothness, and improving tensile properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Preparation of fireproof silicone rubber wallpaper

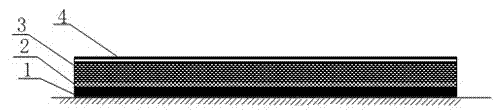

[0048] In order to solve the problems that the wallpaper in the prior art is more or less not fireproof, prone to mildew, not moisture-proof, not resistant to stains, not easy to scrub, etc., this embodiment provides figure 1 The fireproof silicone rubber wallpaper shown includes a base layer 1 attached to the wall by an adhesive and a silicone rubber layer 3 located outside the base layer. The base layer 1 is a fireproof cloth with a thickness of 0.1 mm to 0.5 mm, and the silicone rubber layer 3 is A silicone rubber layer with a thickness of 0.2mm to 2.0mm. Fireproof cloth is also called flame-retardant cloth, specifically glass fiber cloth, basalt fiber fireproof cloth or acrylic cotton fiber fireproof cloth.

[0049] The main structural layer of fire-resistant silicone rubber wallpaper is the silicone rubber layer. Silicone rubber not only has a soft texture, but also makes the wallpaper feel better...

Embodiment 2

[0076] Embodiment 2: Preparation of fireproof silicone rubber wallpaper

[0077] The difference from the above-mentioned Example 1 is that the ratio of parts by weight of raw materials for the preparation of silicone rubber is:

[0078] Polymethylvinylsiloxane raw rubber (molecular weight 650,000-700,000, vinyl content 0.25%-0.35%): 60 parts;

[0079] Fumed silica: 10 parts;

[0080] High temperature resistant agent (silicon carbide): 1 part;

[0081] Flame retardant (magnesium hydroxide): 50 parts;

[0082] Structure control agent (alkoxy terminated small molecule silicone oil): 4 parts;

[0083] Platinum catalyst (chloroplatinic acid tetrahydrofuran solution): 1 part;

[0084] Delayed catalyst (3,7,11-trimethyldodeyn-3-ol): 2 parts;

[0085] Color masterbatch (raw rubber carrier): 15 parts.

[0086] Another difference between this embodiment and embodiment 1 is that when preparing fireproof silicone rubber wallpaper:

Embodiment 3

[0088] Embodiment 3: Preparation of fireproof silicone rubber wallpaper

[0089] The difference from the above-mentioned Example 1 is that the ratio of parts by weight of raw materials for the preparation of silicone rubber is:

[0090] Polymethyl vinyl siloxane raw rubber (molecular weight 600,000-700,000, vinyl content 0.25%-0.35%): 55 parts;

[0091] Fumed silica: 8 parts;

[0092] High temperature resistant agent (silicon carbide): 0.8 parts;

[0093] Flame retardant (aluminum oxide): 45 parts;

[0094] Structure control agent (diphenyldihydroxysilane): 2 parts;

[0095] Platinum catalyst (chloroplatinic acid-divinyltetramethyldisiloxane complex): 0.8 parts;

[0096] Delay catalyst (methyl butynol): 1.6 parts;

[0097] Color masterbatch (raw rubber carrier): 10 parts.

[0098] Another difference between this embodiment and embodiment 1 is that when preparing fireproof silicone rubber wallpaper:

[0099] The thickness of the bridging agent coating is controlled at 0.05...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com