Method for printing by adopting iron printing machine and environment-friendly coating

An environmentally friendly coating and printing method technology, applied in the printing field, can solve the problems of exhaust gas waste heat, high energy consumption of the drying room, environmental impact, etc., and achieve the effects of reducing gas emissions, reducing processes, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

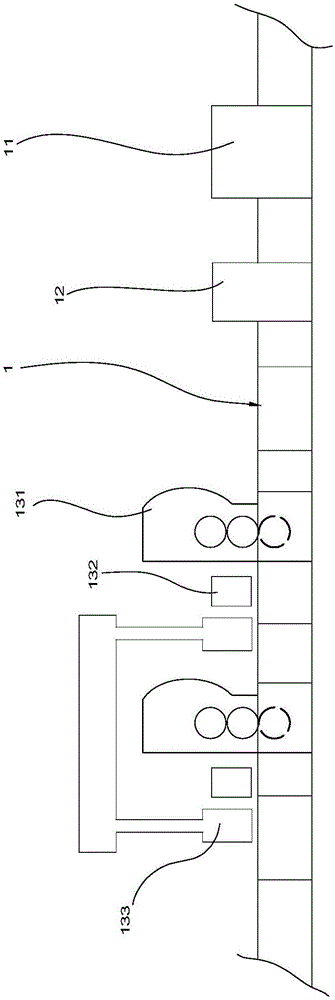

[0020] Such as figure 1 , 2 As shown, the printing method using iron printing machine and environmentally friendly coating in this implementation integrates the laser processor 11 with the traditional iron printing machine. The iron printing machine 1 includes a laser processor 11, a feeding section 12 and a plurality of UV printing units. At the same time, Tinplate with a thickness between 0.12 and 0.40mm is used as the base material, mainly including CC steel grades, large-size rough iron, low tin content or chrome-plated rolled thin steel sheets and secondary cold-rolled thin steel sheets with a thickness of 0.14~0.18mm.

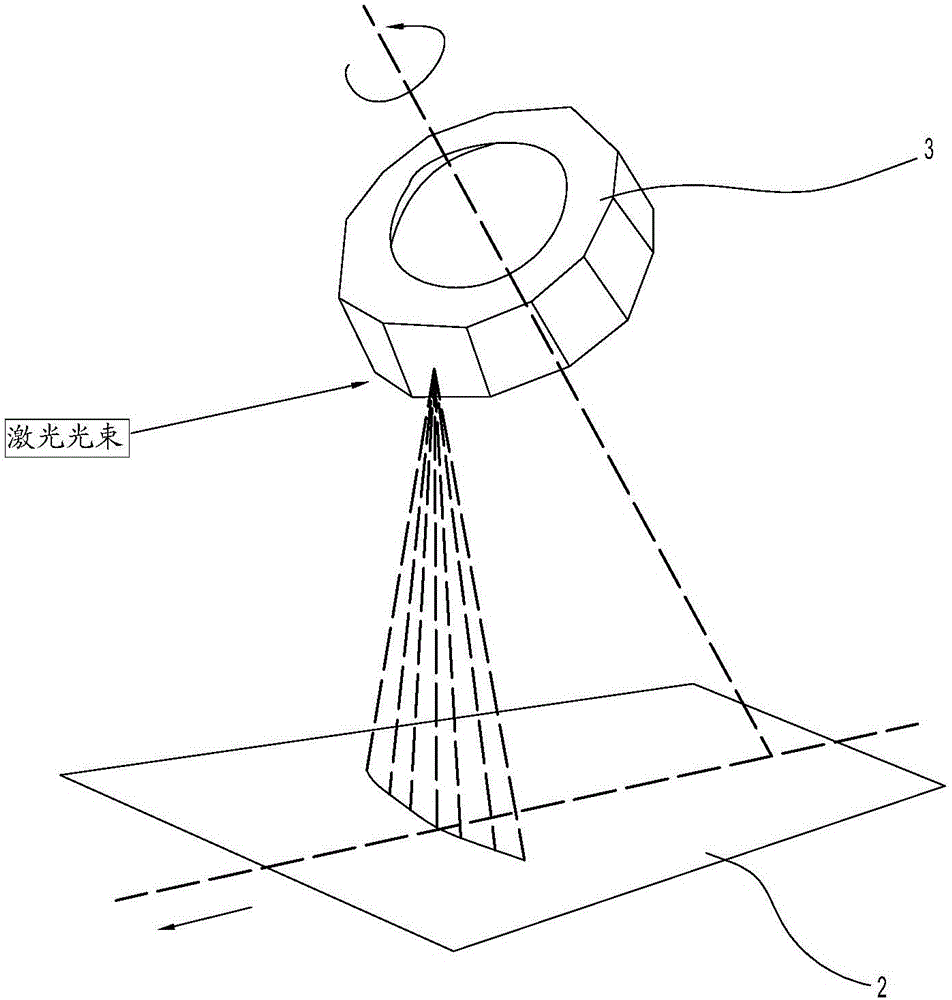

[0021] Wherein, the laser processor 11 is arranged in the feeding section 12 of the iron printing machine 1, and includes a laser generating part for generating a laser beam and a rotating mirror 3 arranged obliquely to reflect the laser beam to the surface of the substrate. The rotating mirror 3 is a polyhedron, The rotation of the rotating mirror 3 is ...

Embodiment 2

[0039] The printing method using iron printing machine and environmental protection coating is the same as in Example 1, wherein the UV ink is made of the following raw materials in parts by weight: 5 parts of fumed white carbon black, 0.5 part of diatomite powder, 25 parts of polyurethane acrylate, polyester acrylate 13 parts, 2 parts of trimethylolpropane triacrylate, 1 part of titanium dioxide, 5 parts of organic pigment, 0.3 part of sodium styrene sulfonate.

[0040] The materials were mixed, heated to 50°C, and stirred for 150 minutes.

Embodiment 3

[0042] The printing method using iron printing machine and environmental protection paint is the same as in Example 1, wherein the UV ink is made of the following raw materials in parts by weight: 10 parts of fumed white carbon black, 1.4 parts of diatomite powder, 28 parts of polyurethane acrylate, polyester acrylate 24 parts, 3 parts of trimethylolpropane triacrylate, 2 parts of titanium dioxide, 10 parts of organic pigments, 0.5 parts of sodium styrene sulfonate.

[0043] The materials were mixed, heated to 56°C, and stirred for 240 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com