Novel green fireproof door core board and process for manufacturing same

A fire-resistant door core board, green technology, applied to fire-resistant doors, etc., can solve the problems of failing to meet Class A fire-proof standards, incapable of factory production, and complicated production processes, and achieve fire-resistant integrity, easy handling, and easy construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

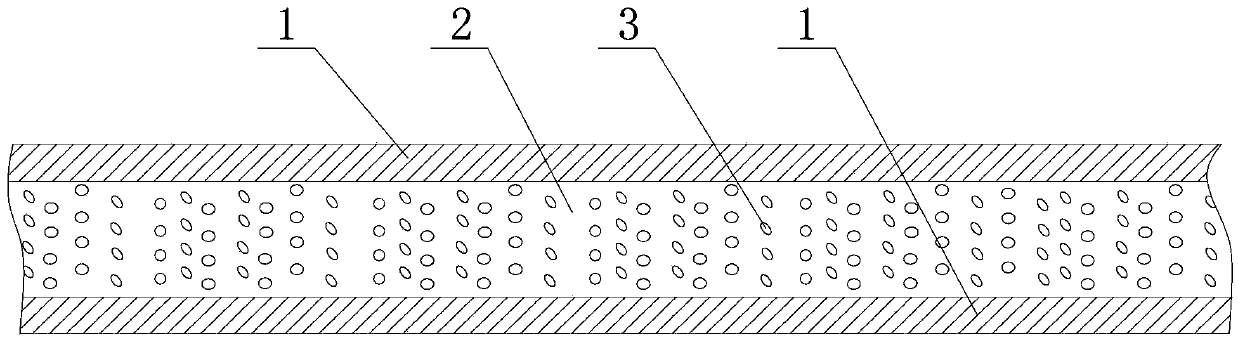

[0023] Such as figure 1 As shown, a novel green fire door core board includes a core board 2 whose thickness is 2-5cm; the upper and lower surfaces of the core board are respectively provided with a surface layer 1 with a thickness of 0.5-1.5cm, and the core board It is a fireproof layer; the components included in the fireproof layer are: cement, expanded particles 3, short filaments, bentonite, light calcium powder, glass water, water, foaming agent and acrylic emulsion.

[0024] In this embodiment, the expanded particles 3 are EPS foam particles. The surface layer is 0.5-1.5cm grid cloth. The thickness of the grid cloth is 0.8cm. The thickness of the core board is 4cm.

[0025] In this embodiment, the mass ratio of the cement, EPS foam particles, short filaments, bentonite, light calcium, glass water, water, foaming agent and acrylic emulsion is: 48-62 parts: 0.1-1.2 parts: 0.1 -1.1 parts: 2-3.5 parts: 1-1.8 parts, 1.5-3 parts: 28-42 parts, 0.1-0.2 parts, 1.3-1.6 parts....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com