A kind of porcelain type fire door core board

A fire-resistant door core board and porcelain technology, applied in fire-resistant doors, door leaves, windows/doors, etc., can solve the problems of high brittleness and easy fracture, and achieve the effect of no decrease in strength, not easy to break, and excellent heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

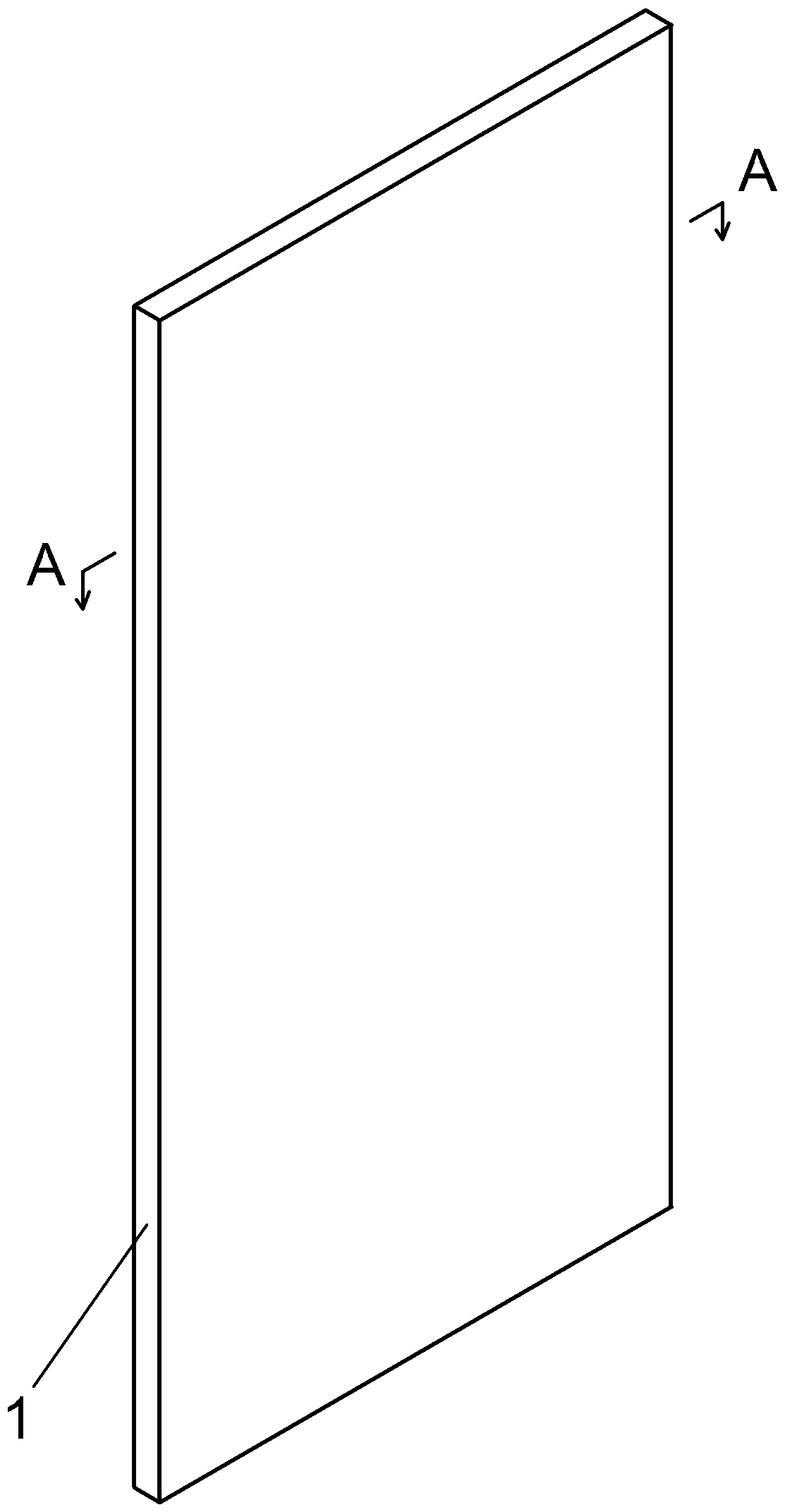

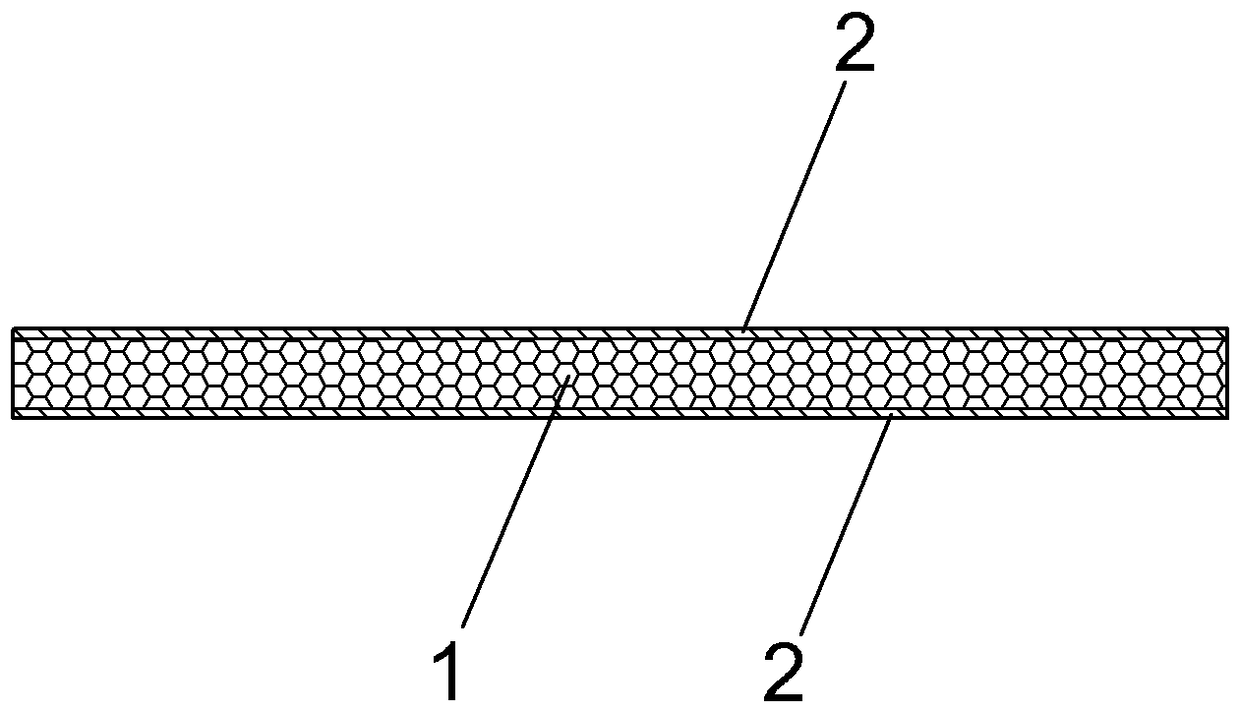

[0011] refer to figure 1 , figure 2 , the overall appearance of the porcelain type fire door core board of the present invention is a cuboid, the middle layer is a foamed cement substrate (1), and a reinforcement layer (2) is arranged on both sides of the foamed cement substrate (1), and the reinforcement layer (2 ) is the mesh bar plus non-fired ceramic covering, and the mesh bar is preferably made of mesh cloth.

[0012] Because the mesh cloth has the characteristics of high strength and light weight, and it can be well combined with the non-fired ceramic cladding material, and forms a firm composite structure board with the foamed cement substrate, so it has advantages over other existing types. Fire door core panels have more and better excellent performance.

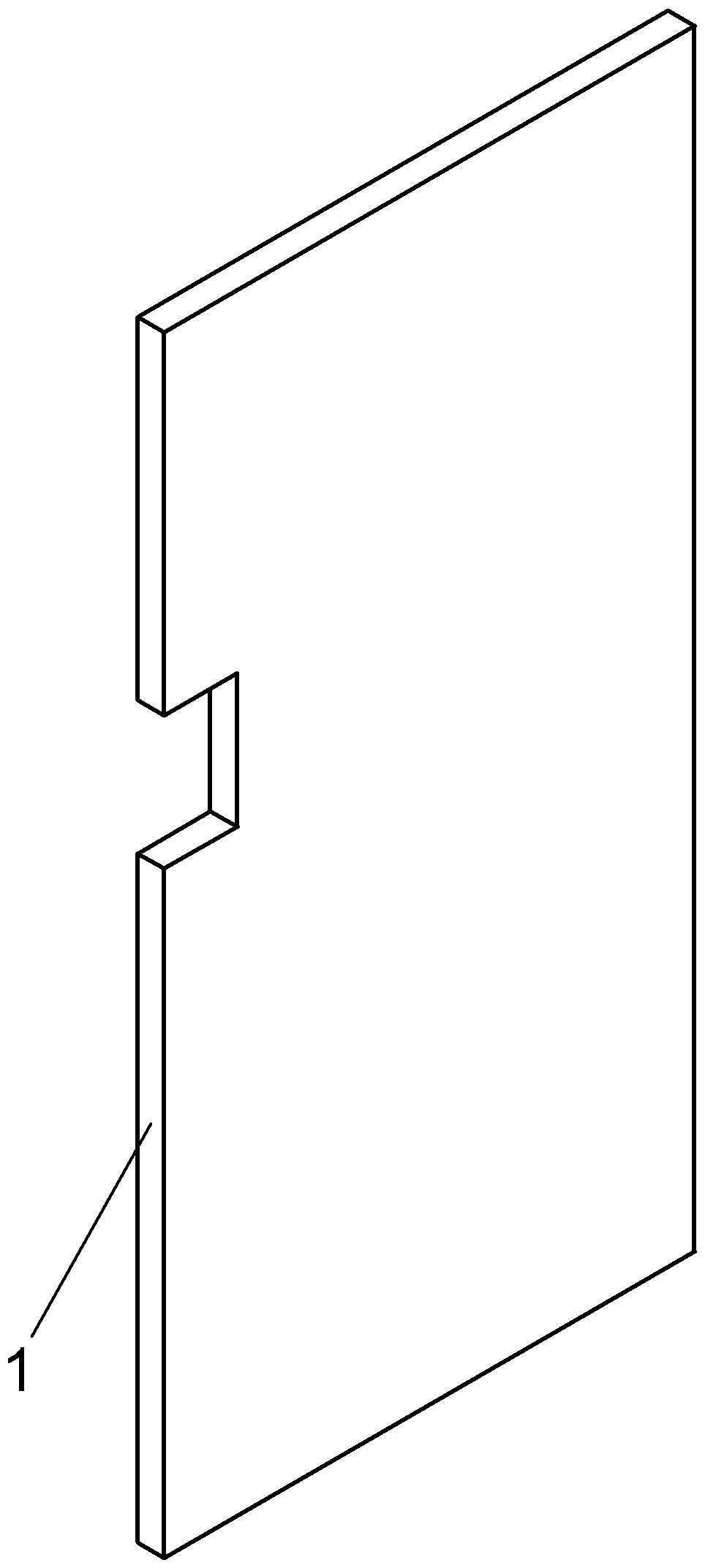

[0013] refer to image 3 , The core plate of the porcelain type fireproof door of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com